Collecting system of core gas in core gas hydrate drilling field

A collection system and hydrate technology, applied in the direction of sampling devices, etc., can solve the problems of large influence of ambient temperature, mixing, low efficiency, etc., achieve the effect of simple and convenient gas sampling process, avoid air mixing, and overcome complex operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]The following is a detailed description of the hydrocarbon gas acquisition system in the natural gas hydrate drilling site of the present invention in conjunction with the accompanying drawings, so that those skilled in the art can understand the solution of the present invention more clearly, but it does not limit the protection of the present invention. scope.

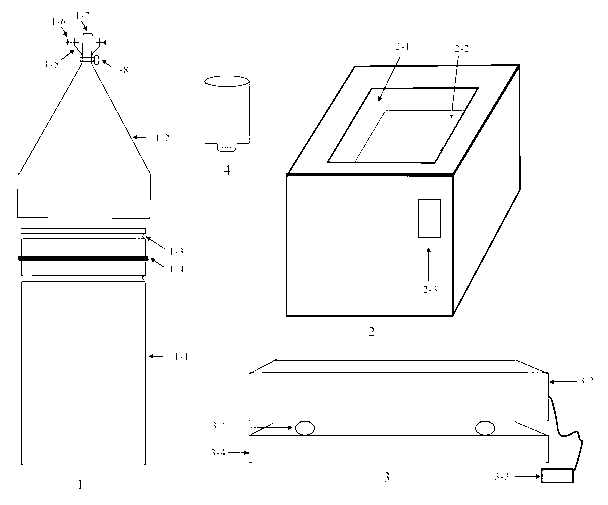

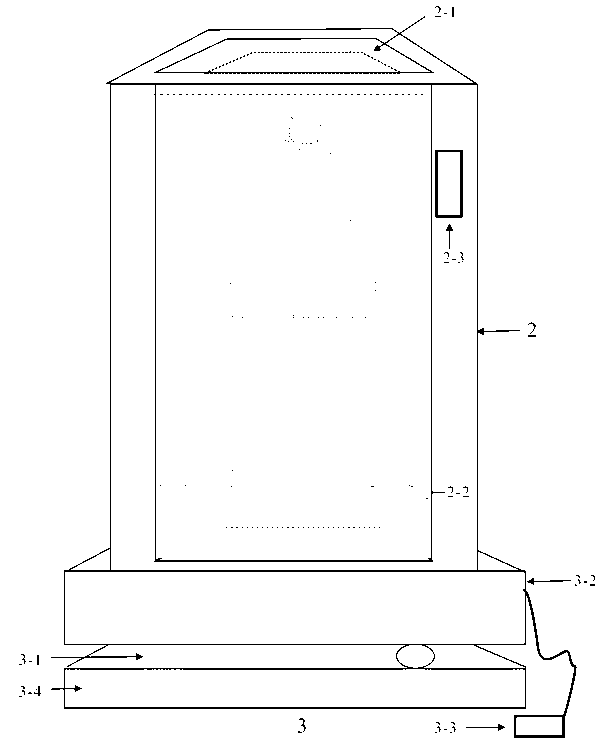

[0041] as attached figure 1 As shown, the hydrocarbon gas collection system in the natural gas hydrate drilling site of the present invention generally includes four parts: a gas collection tank 1, a water bath constant temperature box 2, a shaking table 3 and a gas collection bottle 4 ( figure 1 ). Wherein, the gas collecting tank 1 comprises a tank body 1-1, a tank body cover 1-2, a sealing ring slot 1-3, a sealing ring 1-4, a gas collecting bottle bracket 1-5, a fixing screw 1-6, Gas collection conduit 1-7, gas collection conduit switch 1-8; water bath constant temperature box 2 specifically includes water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com