Follow-up device of coal mine fully-mechanized coal winning machine belt support

A belt support and follow-up device technology is applied in the direction of slitting machinery, earth-moving drilling and mining, etc., which can solve the problems of not being able to go up and down, and the support of the excavation can move forward synchronously, so as to achieve the effect of improving safety production and improving safety production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is further described below in conjunction with embodiment; The following embodiment is not for the limitation of the present invention, only as the mode of supporting the realization of the present invention, any equivalent structural replacement within the technical framework disclosed in the present invention, all is the present invention. the scope of protection of the invention;

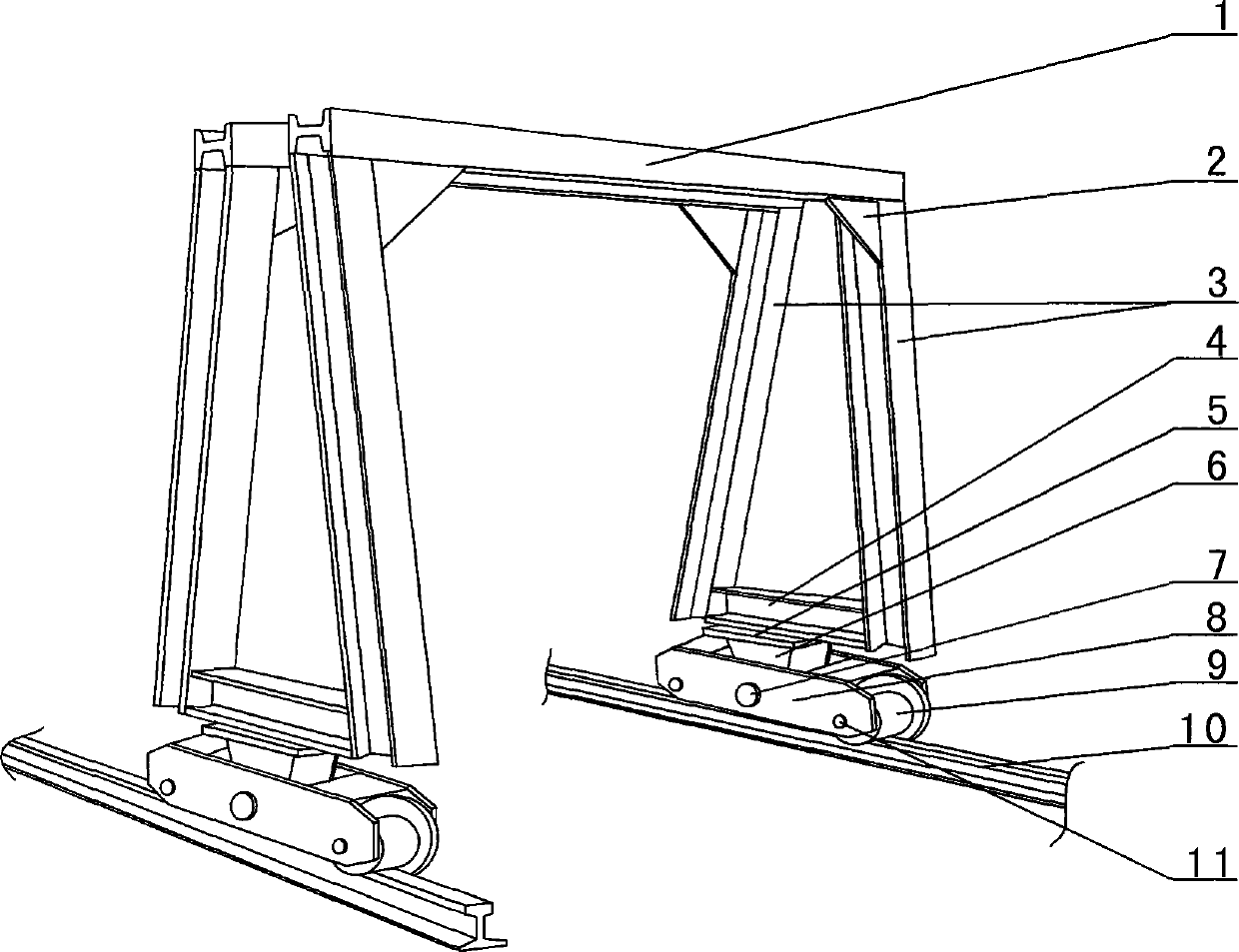

[0017] combined with figure 1 Or the follower device of the belt bracket of the fully mechanized excavator in coal mine described in 2, comprising an upper supporting frame body, a connecting plate 5, a shock absorbing mechanism, a shaft 7, a guard plate 8 and a wheel 9, the upper supporting frame body is two, and the working The two ends of the beam 1 are fixed on the upper ends of the two upper supporting frame bodies, the upper supporting frame body includes the I-shaped steel supporting beam 1, the I-shaped steel oblique support 3 and the bottom connecting I-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com