Method for treating waste residue by using arsenious wastewater in clean mode

A waste water treatment and waste residue technology, applied in metallurgy and gold smelting fields, can solve the problems of poor arsenic comprehensive recovery effect and low recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

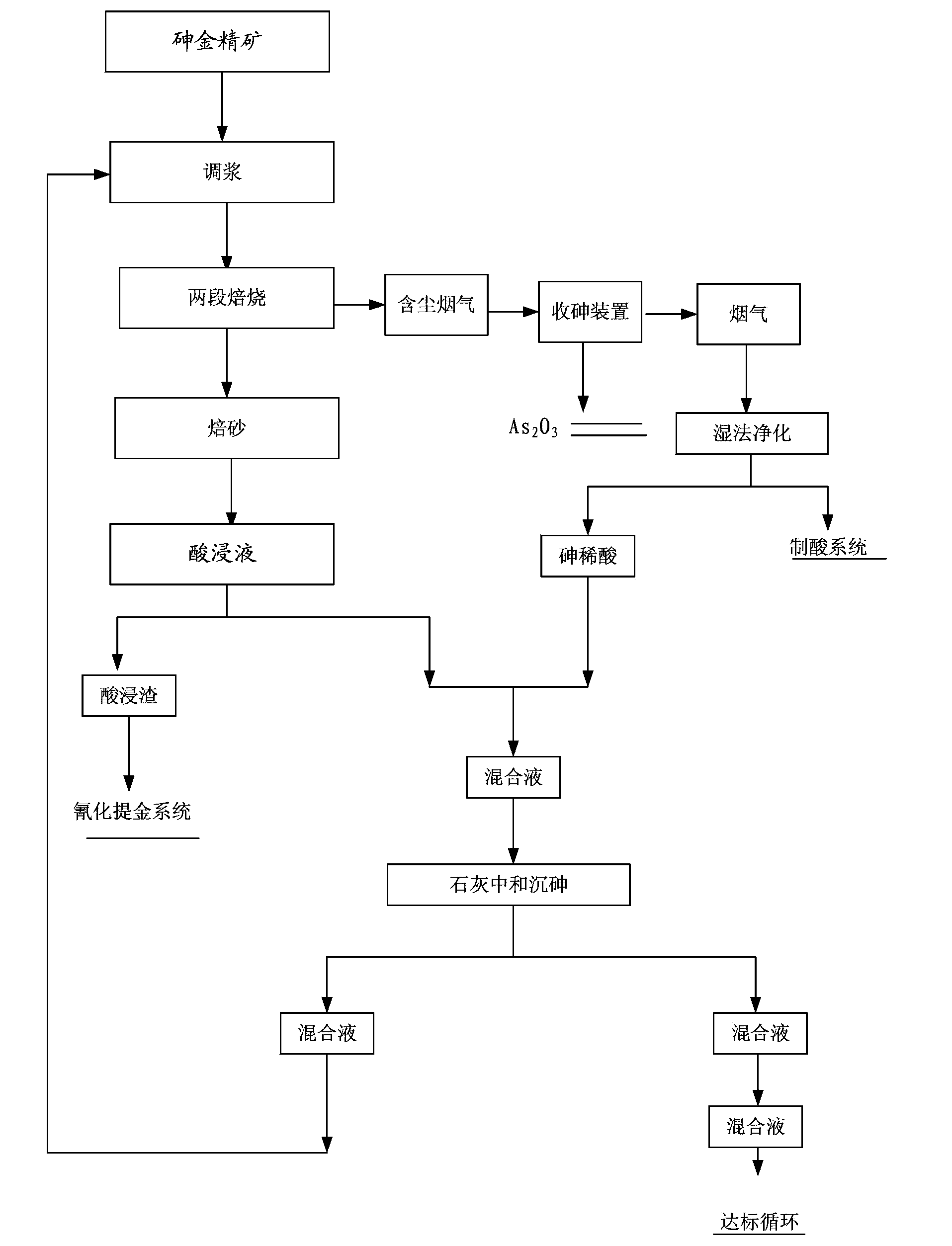

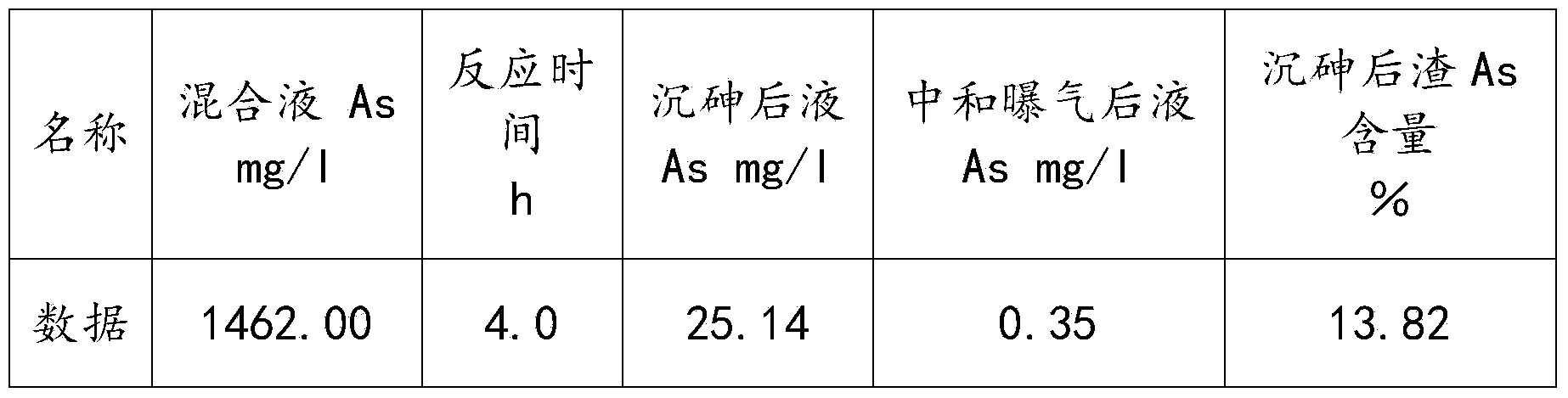

[0019] A method for cleanly utilizing arsenic-containing wastewater to treat waste residues, comprising the following steps: the arsenic-containing gold concentrate is subjected to ore blending and slurry adjustment, and then undergoes two-stage roasting pretreatment at a roasting temperature of 630°C to 650°C to generate dust-containing flue gas And baked sand, dusty flue gas namely arsenic, carbon, sulfur and As 2 o 3 , CO 2 , SO 2 The gaseous form enters the flue gas and recovers As through the bag arsenic collection device 2 o 3 , and then carry out wet purification through the acid system to produce dilute arsenic acid, wherein the dilute arsenic acid contains 1235.00 mg / l of arsenic; the baked sand is leached out of arsenic and copper by 5% sulfuric acid solution to produce arsenic acid leaching solution. The leaching time was 1.5 hours, and the arsenic content in the pickling solution was 1689.00mg / l, wherein the mass ratio of baked sand to 5% sulfuric acid solution...

Embodiment 2

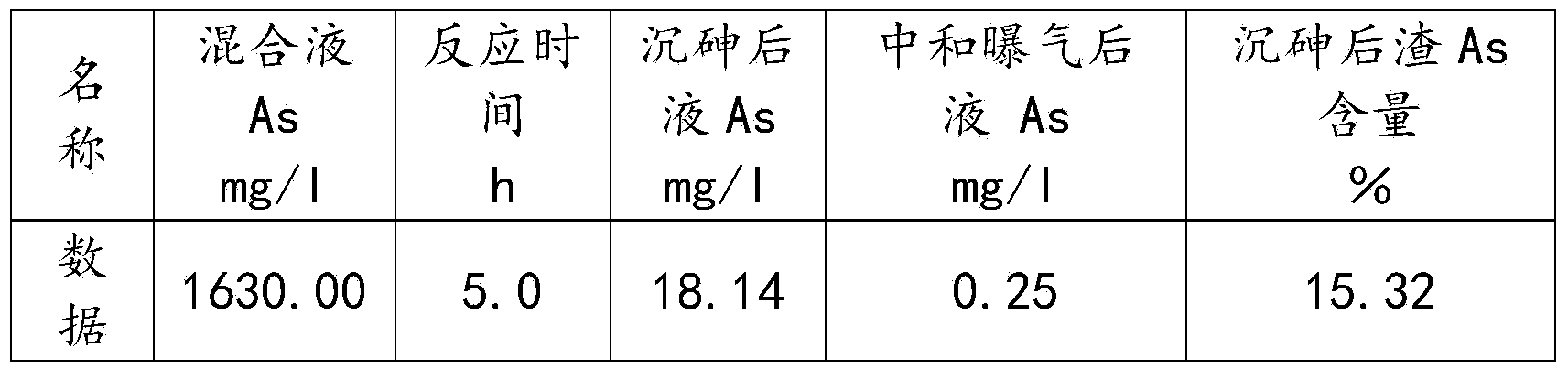

[0023] A method for cleanly utilizing arsenic-containing wastewater to treat waste residues, comprising the following steps: the arsenic-containing gold concentrate is subjected to ore blending and slurry adjustment, and then undergoes two-stage roasting pretreatment at a roasting temperature of 630°C to 650°C to generate dust-containing flue gas And baked sand, dusty flue gas namely arsenic, carbon, sulfur and As 2 o 3 , CO 2 , SO 2 The gaseous form enters the flue gas and recovers As through the bag arsenic collection device 2 o 3 , and then carry out wet purification through the acid system to produce dilute arsenic acid, wherein the dilute arsenic acid contains 1535.00 mg / l of arsenic; the baked sand is leached out of arsenic and copper by 10% sulfuric acid solution to produce arsenic acid leaching solution. The leaching time is 2.5 hours, the arsenic content of the acid leaching solution is 1726.00mg / l, the mass ratio of baked sand to 10% sulfuric acid solution is 3:1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com