Method for treating waste residue by using arsenious wastewater in clean mode

A technology for waste water treatment and waste residue, applied in the fields of metallurgy and gold smelting, can solve the problems of low recovery rate and poor comprehensive recovery effect of arsenic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

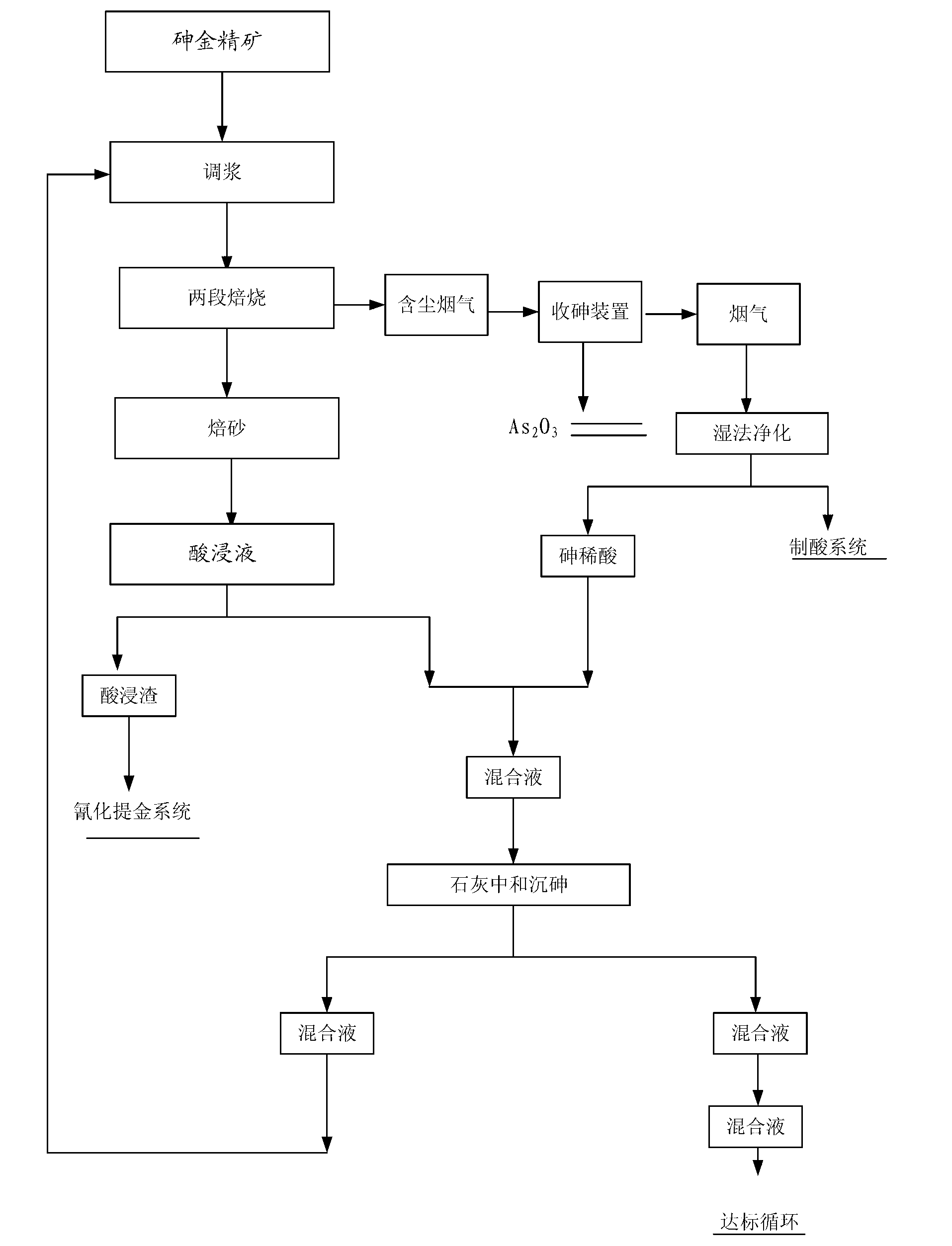

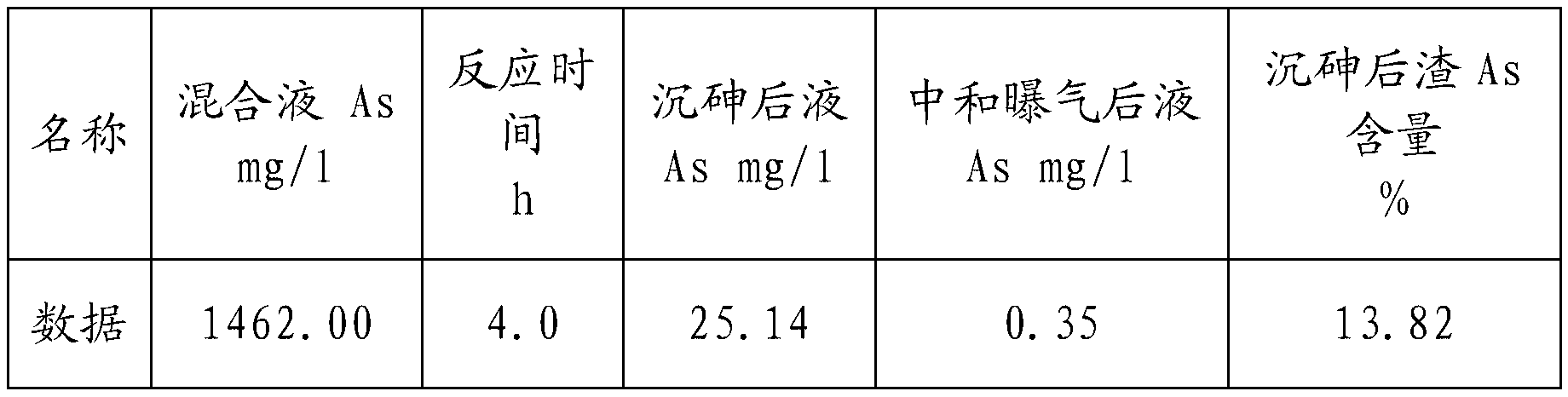

[0019] A method for cleanly utilizing arsenic-containing wastewater to treat waste residues, comprising the following steps: the arsenic-containing gold concentrate is subjected to ore blending and slurry adjustment, and then undergoes two-stage roasting pretreatment at a roasting temperature of 630°C to 650°C to generate dust-containing flue gas And baked sand, dusty flue gas namely arsenic, carbon, sulfur and As 2 o 3 , CO 2 , SO 2 The gaseous form enters the flue gas and recovers As through the bag arsenic collection device 2 o 3 , and then carry out wet purification through the acid system to produce dilute arsenic acid, wherein the dilute arsenic acid contains 1235.00 mg / l of arsenic; the baked sand is leached out of arsenic and copper by 5% sulfuric acid solution to produce arsenic acid leaching solution, The leaching time was 1.5 hours, and the arsenic content in the acid leaching solution was 1689.00mg / l, wherein the mass ratio of baked sand to 5% sulfuric acid sol...

Embodiment 2

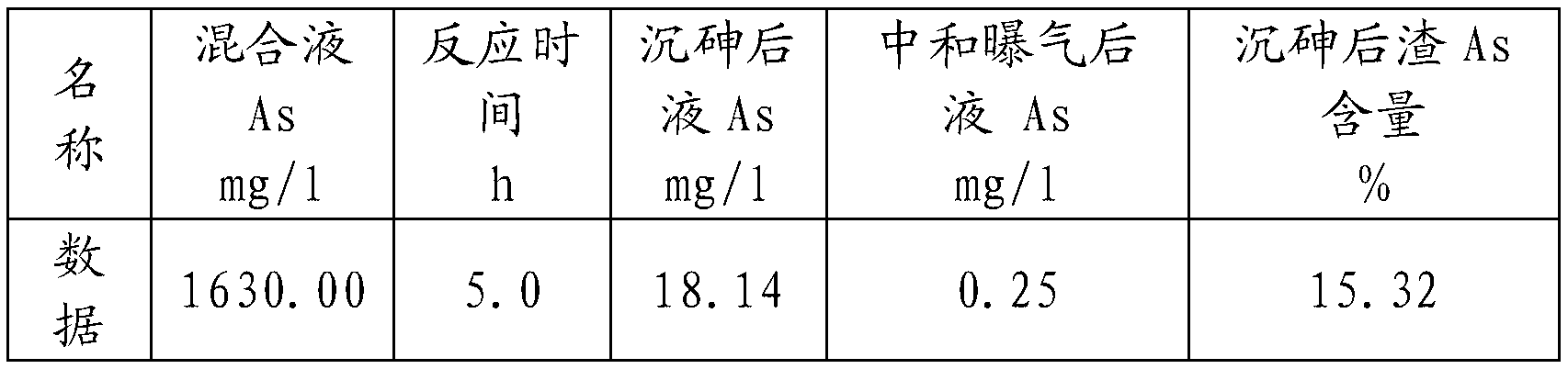

[0023] A method for cleanly utilizing arsenic-containing wastewater to treat waste residues, comprising the following steps: the arsenic-containing gold concentrate is subjected to ore blending and slurry adjustment, and then undergoes two-stage roasting pretreatment at a roasting temperature of 630°C to 650°C to generate dust-containing flue gas And baked sand, dusty flue gas namely arsenic, carbon, sulfur and As 2 o 3 , CO 2 , SO 2 The gaseous form enters the flue gas and recovers As through the bag arsenic collection device 2 o 3 , and then carry out wet purification through the acid system to produce dilute arsenic acid, wherein the arsenic content of dilute arsenic acid is 1535.00mg / l; the baked sand is leached out of arsenic and copper by 10% sulfuric acid solution to produce arsenic acid leaching solution. The leaching time is 2.5 hours, the amount of arsenic in the acid leaching solution is 1726.00 mg / l, the mass ratio of baked sand to 10% sulfuric acid solution is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com