Acidic lasting wall built-up type toilet bowl cleaner and preparation method thereof

A cleaning agent and long-lasting technology, which is applied in the field of acidic and long-lasting wall-mounted toilet bowl cleaning agent and its preparation, can solve the problems of reduced cleaning frequency, poor corrosion inhibition effect, and single function, and achieve ideal product cost performance and good thixotropic properties , strong antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

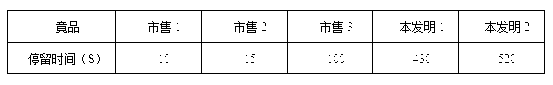

Image

Examples

Embodiment 1

[0078] Step 1: Prepare raw materials according to the following mass percentages:

[0079] Fatty amine polyoxyethylene ether 1%;

[0080] Fatty alcohol polyoxyethylene ether 0.01%;

[0081] Acid 1%;

[0082] Acrylic polymer 0.1%;

[0083] Inorganic salt 1%;

[0084] Hydroxyethylidene diphosphonic acid 0.1%;

[0085] Fragrance 0.1%;

[0086] Pigment 0.00001%;

[0087] water balance ;

[0088] Step 2: Add water, colorant and acrylic polymer into the configuration tank, and stir, then add acid, and stir until completely dissolved;

[0089] Step 3: While stirring, add fatty amine polyoxyethylene ether until it dissolves completely;

[0090] Step 4: Add fatty alcohol polyoxyethylene ether, inorganic salt, hydroxyethylidene diphosphonic acid and essence under continuous stirring;

[0091] Step five: semi-finished products are subjected to aging treatment;

[0092] Step 6: Sampling inspection, finished product packaging.

[0093] in:

[0094] The fatty amine polyoxyethyl...

Embodiment 2

[0102] Step 1: Prepare raw materials according to the following mass percentages:

[0103] Fatty amine polyoxyethylene ether 4%;

[0104] Fatty alcohol polyoxyethylene ether 0.4%;

[0105] Acid 4%;

[0106] Acrylic polymer 0.4%;

[0107] Inorganic salt 2%;

[0108] Hydroxyethylidene diphosphonic acid 0.4%;

[0109] Flavor 0.2%;

[0110] Pigment 0.004%;

[0111] water balance ;

[0112] Step 2: Add water, colorant and acrylic polymer into the configuration tank, and stir, then add acid, and stir until completely dissolved;

[0113] Step 3: While stirring, add fatty amine polyoxyethylene ether until it dissolves completely;

[0114] Step 4: Add fatty alcohol polyoxyethylene ether, inorganic salt, hydroxyethylidene diphosphonic acid and essence under continuous stirring;

[0115] Step five: semi-finished products are subjected to aging treatment;

[0116] Step 6: Sampling inspection, finished product packaging.

[0117] in:

[0118] The fatty amine polyoxyethylene et...

Embodiment 3

[0126] Step 1: Prepare raw materials according to the following mass percentages:

[0127] Fatty amine polyoxyethylene ether 6%;

[0128] Fatty alcohol polyoxyethylene ether 0.6%;

[0129] Acid 6%;

[0130] Acrylic polymer 0.6%;

[0131] Inorganic salt 3%;

[0132] Hydroxyethylidene diphosphonic acid 0.6%;

[0133] Fragrance 0.3%;

[0134] Colorant 0.006%;

[0135] water balance ;

[0136] Step 2: Add water, colorant and acrylic polymer into the configuration tank, and stir, then add acid, and stir until completely dissolved;

[0137] Step 3: While stirring, add fatty amine polyoxyethylene ether until it dissolves completely;

[0138] Step 4: Add fatty alcohol polyoxyethylene ether, inorganic salt, hydroxyethylidene diphosphonic acid and essence under continuous stirring;

[0139] Step five: semi-finished products are subjected to aging treatment;

[0140] Step 6: Sampling inspection, finished product packaging.

[0141] in:

[0142] The fatty amine polyoxyethylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com