Preparation method of high-temperature resistant hot-melt pressure-sensitive adhesive

A hot-melt pressure-sensitive adhesive, high-temperature technology, applied in the direction of adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc., can solve the problems of adverse effects of hot-melt adhesive use temperature, etc., and achieve simple and easy raw material addition process Good, easy to process, high transparency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

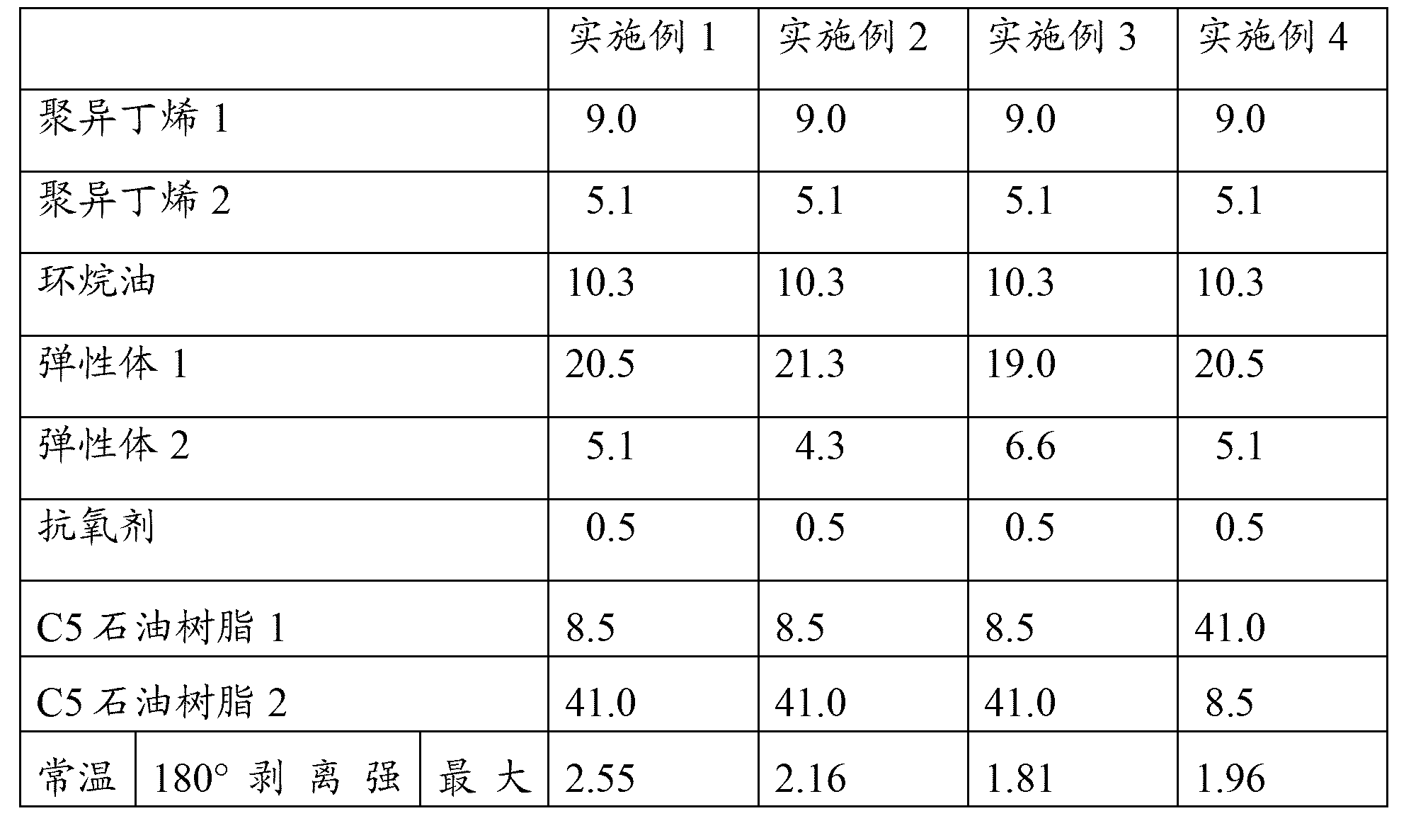

Embodiment 1

[0015] Heat the equipment to 160°C, add 9.0kg of polyisobutylene 1, 10.3kg of naphthenic oil and 5.1kg of polyisobutylene 2, start stirring, add 20.5kg of elastomer 1 and 5.1kg of elastomer 2, add 0.5kg of antioxidant, and then Add 8.5kg C5 petroleum resin 1 and 41.0kg C5 petroleum resin 2, keep the temperature and stir for 2 hours. Measure its performance. See Table 1.

Embodiment 2

[0017] Heat the equipment to 160°C, add 9.0kg of polyisobutylene 1, 10.3kg of naphthenic oil and 5.1kg of polyisobutylene 2, start stirring, add 21kg of elastomer 1 and 4.3kg of elastomer 2, add 0.5kg of antioxidant, and then add 8.5kg C5 petroleum resin 1 and 41.0kg C5 petroleum resin 2, keep the temperature and stir for 2 hours. Measure its performance. See Table 1.

Embodiment 3

[0019] Heat the equipment to 160°C, add 9.0kg of polyisobutylene 1, 10.3kg of naphthenic oil and 5.1kg of polyisobutylene 2, start stirring, add 19.0kg of elastomer 1 and 6.6kg of elastomer 2, add 0.5kg of antioxidant, and then Add 8.5kg C5 petroleum resin 1 and 41.0kg C5 petroleum resin 2, keep the temperature and stir for 2 hours. Measure its performance. See Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com