Two-component water-based coating composition

A water-based paint and composition technology, applied in the direction of coating, can solve the problem of water resistance reduction of the coating film, and achieve the effect of reducing the content, excellent long-term storage, and reducing the discharge amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041]In the preparation of an acrylic emulsion having a carboxyl group, the emulsion polymerization in an aqueous medium can be carried out by, for example, dissolving an emulsifier in water or an aqueous medium containing a hydrophilic organic solvent such as alcohol, glycol, etc., under heating and stirring , a mixture of α,β-ethylenically unsaturated monomers used as raw materials and a polymerization initiator are added dropwise. A mixture obtained by mixing α,β-ethylenically unsaturated monomers used as raw materials may be previously emulsified using an emulsifier and water.

[0042] Examples of polymerization initiators that can be suitably used for emulsion polymerization include azo-based oily compounds (for example, azobisisobutyronitrile, 2,2'-azobis(2-methylbutyronitrile) and 2 ,2'-azobis(2,4-dimethylvaleronitrile), etc.), and aqueous compounds (for example, anionic 4,4'-azobis(4-cyanovaleric acid), 2,2 -Azobis(N-(2-carboxyethyl)-2-methylpropionamidine and cation...

preparation example 1

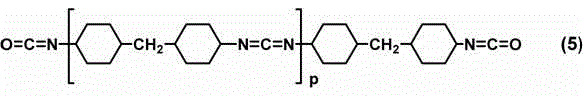

[0109] Preparation Example 1: Preparation of Carbodiimide Compounds Having Isocyanate Groups at Both Terminals

[0110] In 2500 parts of 4,4-dicyclohexylmethane diisocyanate, add 25 parts of 3-methyl-1-phenyl-phosphorol-2-ene-1-oxide as a carbodiimidation catalyst, It was made to react at 170 degreeC until the isocyanate equivalent weight became 436, and the carbodiimide compound 1 which has isocyanate group at both terminals was prepared. Carbodiimide compound 1 has 2.8 carbodiimide groups per molecule.

preparation example 2

[0111] Preparation Example 2: Preparation of Aqueous Dispersion of Carbodiimide Compound

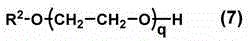

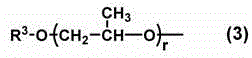

[0112] As shown in Table 1, in 872 parts of the carbodiimide compound 1 prepared in Preparation Example 1, 567 parts of Neupore LB-65 (polypropylene glycol monobutyl ether number average repeat number 5 manufactured by Sanyo Chemical Industry) and MPG-081 ( Polyethylene glycol monomethyl ether manufactured by Nippon Emulsifier (Number average repeat number 15) 225 parts, reacted at 160°C until the absorption from isocyanate group in IR disappeared. It was further cooled to 60°C, and 2496 parts of deionized water was slowly added for emulsification to obtain a milky white carbodiimide aqueous dispersion 1 with a solid content of 40%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com