Preparation method of surface-grafted modified nanocellulose crystal

A surface graft modification and nanocellulose technology is applied in the field of preparation of surface graft modified nanocellulose crystals, which can solve the problems of easy agglomeration interface compatibility and the like, and achieves low cost, abundant raw material sources and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

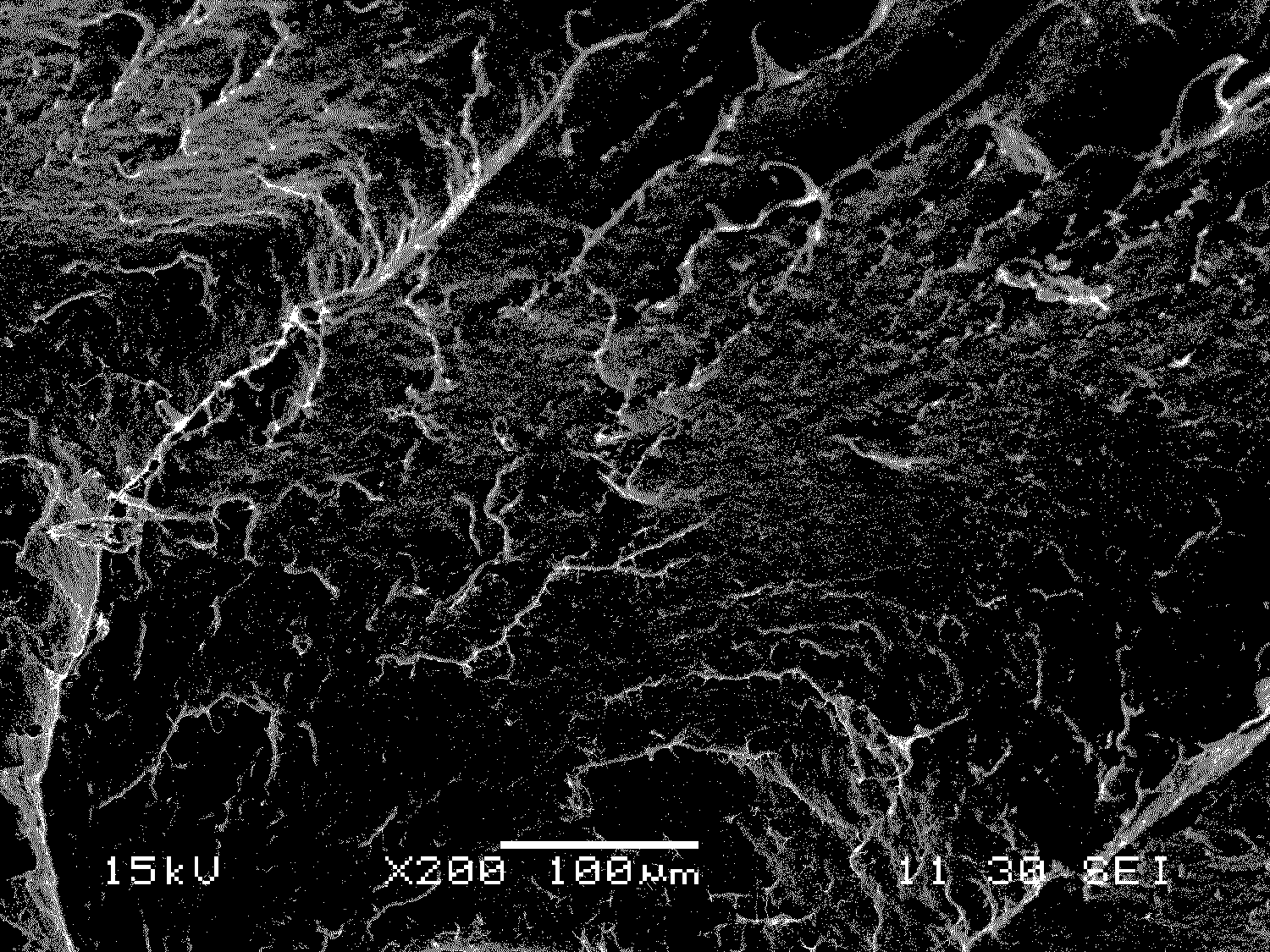

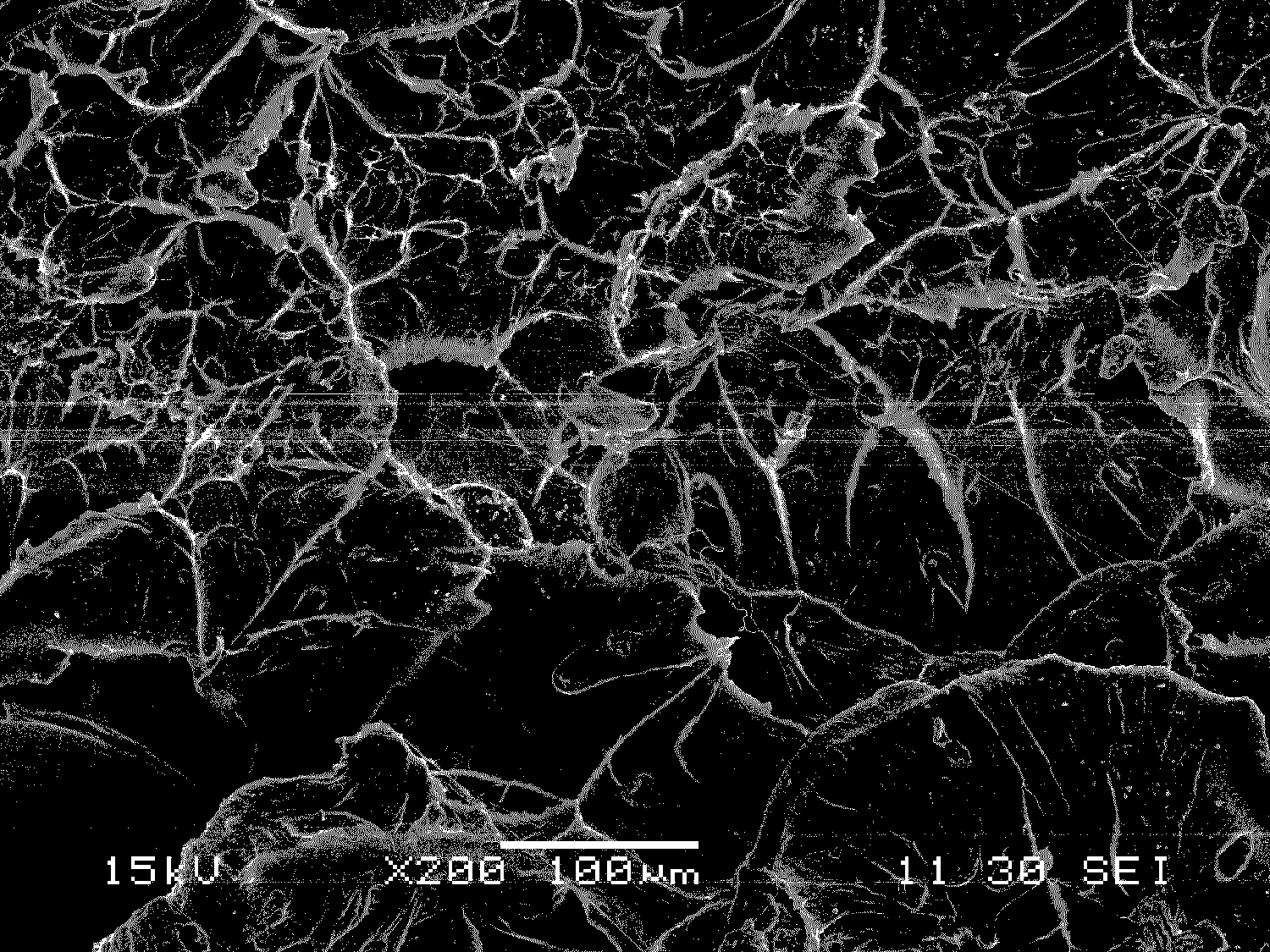

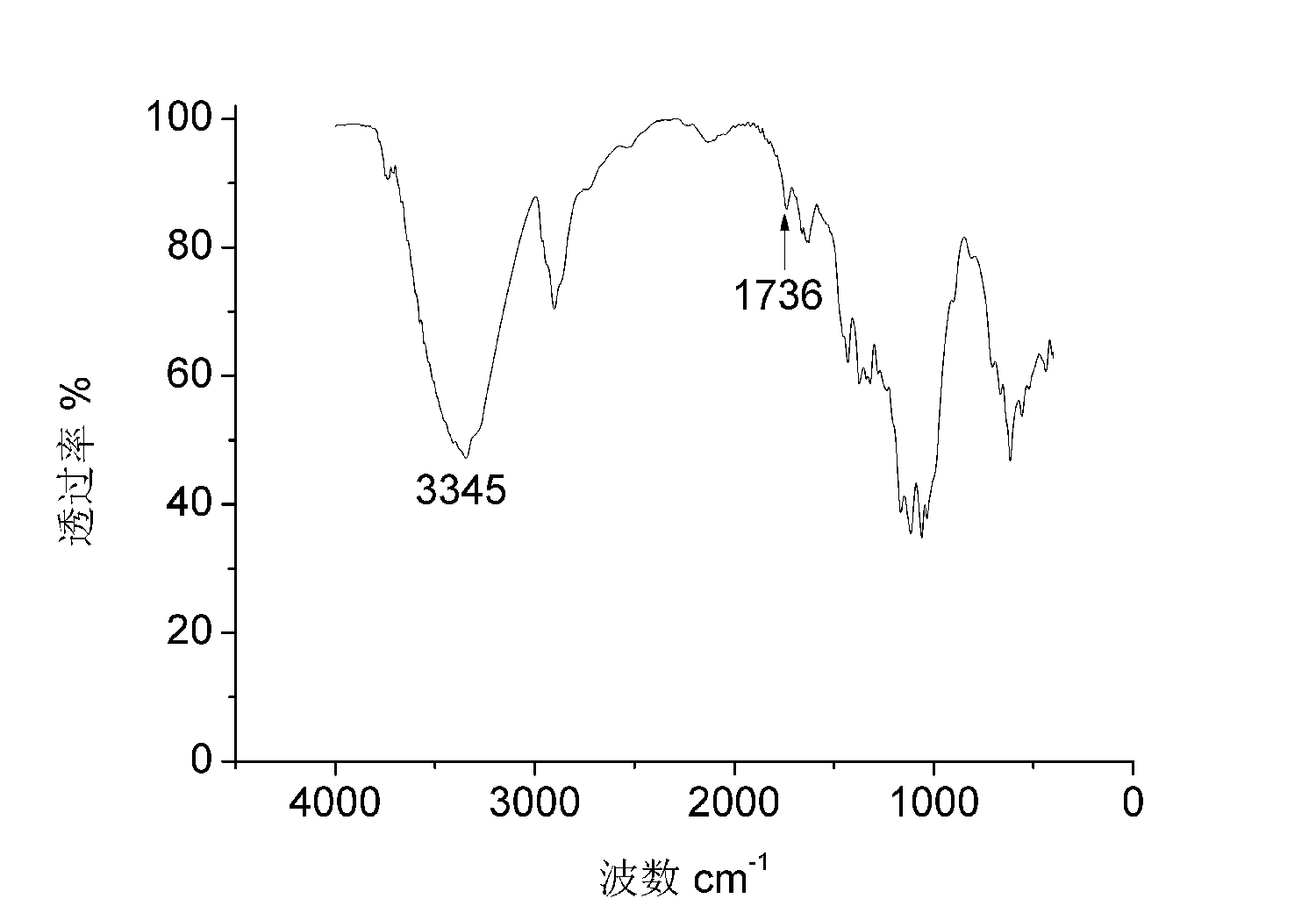

[0023] Add 120ml of toluene and 6g of nano-cellulose crystals to a 250ml four-necked bottle. After ultrasonic dispersion for 30 minutes, add 4g of maleic anhydride and 0.1g of 4-dimethylaminopyridine, and install a stirrer, condenser, thermometer and dripping liquid Funnel, stirred at 50°C for 3 hours, then heated up to 72-73°C, added 0.03g of BPO, 30 minutes later, added 6g of vinyl acetate dropwise with a dropping funnel, added dropwise within 2 hours, and continued to react for 8 hours. The reaction solution is centrifuged three times, washed with acetone, and freeze-dried to obtain surface-grafted modified nano-cellulose crystals. The nanocomposite material was prepared by mixing grafted modified nanocellulose crystals and polylactic acid through a solution, and the content of grafted nanocellulose crystal powder was 6%. The tensile strength and elongation at break of the composite material were measured, which were 41.7MPa and 21.4%, respectively, compared with the unmodi...

Embodiment 2

[0025] Add 120ml of toluene and 6g of nano-cellulose crystals to a 250ml four-necked bottle. After ultrasonic dispersion for 30 minutes, add 4g of maleic anhydride and 0.1g of 4-dimethylaminopyridine, and install a stirrer, condenser, thermometer and dripping liquid Funnel, react at 50°C for 3 hours under stirring, then heat up to 72-73°C, add 0.03g of BPO, after 30 minutes, drop a mixed solution of 4.5g of vinyl acetate and 1.5g of butyl acrylate with the dropping funnel, for 2 hours After the internal dropwise addition, the reaction was continued for 8 hours, the reaction solution was centrifuged three times, washed with acetone, and freeze-dried to obtain surface-grafted modified nanocellulose crystals. The nanocomposite material was prepared by mixing the grafted modified nano-cellulose crystal powder and polylactic acid through a solution method, and the content of the grafted nano-cellulose crystal powder was 2%. The tensile strength and elongation at break of the compos...

Embodiment 3

[0027] The preparation method of surface graft modified nanocellulose crystals is the same as that in Example 2. The nano-composite material was prepared by mixing grafted modified nano-cellulose crystals and polylactic acid through a solution method, and the content of grafted nano-cellulose crystal powder was 4%. The tensile strength and elongation at break of the composite were measured, and they were 34.2MPa and 26.1%, respectively, compared with the unmodified nanocellulose / polylactic acid composite prepared by the same method and ratio (26MPa and 15.2%, respectively) An increase of 31.5% and 71%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation at break | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com