Preparation method of sodium chondroitin sulfate

A technology of sodium chondroitin sulfate and cartilage, applied in the biological field, can solve the problems of heavy metals, nitrogen content, residue on ignition exceeding the standard, failing to meet standards and export standards, low content of sodium chondroitin sulfate, etc., to reduce production costs , The dry matter yield increases, and the effect of enhancing the added value of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

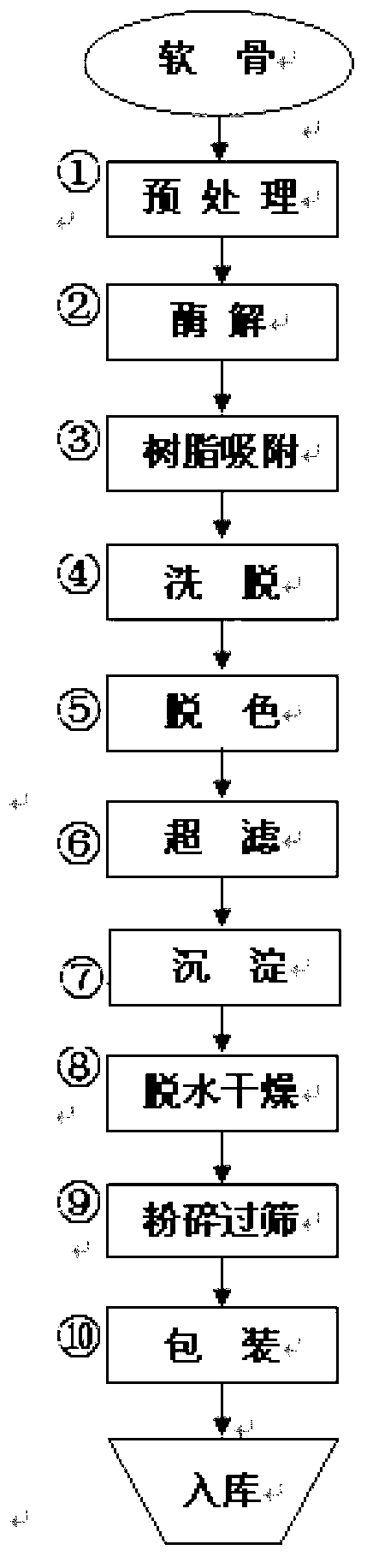

Image

Examples

Embodiment 1

[0023] Embodiment 1, preparation sodium chondroitin sulfate

[0024] One, prepare sodium chondroitin sulfate according to the following steps:

[0025] (1) Raw material pretreatment: Put cartilage tissues such as throat bones, nasal middle bones, and trachea of pigs and cattle into washing jars, soak them in water until they are completely submerged, raise the temperature to about 80°C, stir and wash repeatedly, and remove meat residues, floating Oil, impurities, until the raw materials are washed.

[0026] Put the washed raw materials into the digestion tank, add purified water until the cartilage is completely submerged, and then heat the ingredients. After boiling, turn off the steam and simmer the oil for 2 hours. After the raw materials are cooked, remove all the slick oil.

[0027] (2) Enzymolysis: Cool the cooked raw materials to 30°C, add salt with 1% cartilage weight, and adjust the pH value to 8 with dilute alkali solution (40% NaOH aqueous solution: 100ml water ...

Embodiment 2

[0061] Embodiment 2, preparation sodium chondroitin sulfate

[0062] One, prepare sodium chondroitin sulfate according to the following steps:

[0063] (1) Raw material pretreatment: Put cartilage tissues such as throat bones, nasal middle bones, and trachea of pigs and cattle into washing jars, soak them in water until they are completely submerged, raise the temperature to about 80°C, stir and wash repeatedly, and remove meat residues, floating Oil, impurities, until the raw materials are washed.

[0064] Put the washed raw materials into the digestion tank, add purified water until the cartilage is completely submerged, and then heat the ingredients. After boiling, turn off the steam and simmer the oil for 3 hours. After the raw materials are cooked, remove all the slick oil.

[0065] (2) Enzymolysis: Cool the cooked raw materials to 40°C, add salt with 3.5% cartilage weight, and adjust the pH value to 11 with dilute alkali solution (40% NaOH aqueous solution: 100ml wat...

Embodiment 3

[0091] Embodiment 3, preparation sodium chondroitin sulfate

[0092] One, prepare sodium chondroitin sulfate according to the following steps:

[0093] (1) Raw material pretreatment: Put cartilage tissues such as throat bones, nasal middle bones, and trachea of pigs and cattle into washing jars, soak them in water until they are completely submerged, raise the temperature to about 80°C, stir and wash repeatedly, and remove meat residues, floating Oil, impurities, until the raw materials are washed.

[0094] Put the washed raw materials into the digestion tank, add purified water until the cartilage is completely submerged, and then heat the ingredients. After boiling, turn off the steam and simmer the oil for 2.5 hours. After the raw materials are cooked, remove all the slick oil.

[0095] (2) Enzymolysis: Cool the cooked raw materials to 35°C, add salt with 2% cartilage weight, and adjust the pH value to 10 with dilute alkali solution (40% NaOH aqueous solution: 100ml wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com