Dual-wavelength mould laser welding machine

A laser welding machine, laser welding technology, applied in laser welding equipment, lasers, welding equipment and other directions, can solve the problems of laser welding and processing, unable to form a stable molten pool, hinder the application of laser welding technology, etc., and achieve good welding effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings.

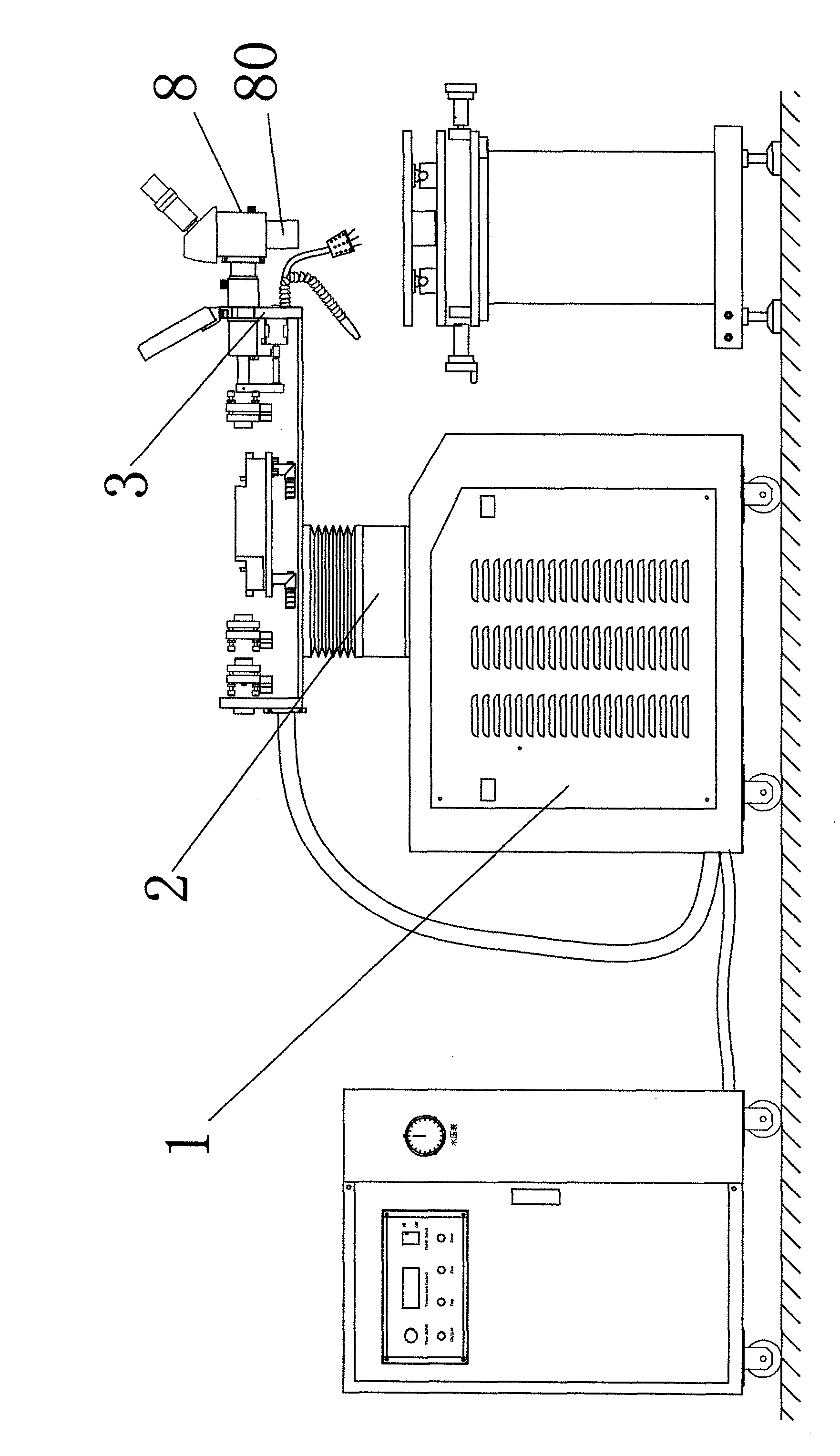

[0010] Please refer to figure 1 Shown is a preferred embodiment of the present invention. In this preferred embodiment, in order to achieve the above-mentioned purpose, the articulated optical fiber transmission mold laser welding machine of the present invention adopts the following technical scheme: comprising a main chassis 1, a laser generator 8, and a laser welding arm 2 arranged on the main frame , the main machine box 1 is provided with a main machine, the end of the laser welding arm 8 has a welding head 80 with a laser generator, the laser generator includes a laser resonator, and the dual-wavelength mold laser welding machine also includes a wavelength switching module group, the wavelength switching module includes a frequency doubling crystal insertion device 3 arranged at the laser resonator for inserting a frequency doubling crystal into the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com