Squeeze casting method for aluminum piston of internal combustion engine

A squeeze casting and internal combustion engine technology, applied in the direction of pistons, mechanical equipment, engine components, etc., can solve the problems of loose structure of castings, low product qualification rate, high casting cost, etc., and achieve high scrap rate, low process cost and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A method for casting an aluminum piston of an internal combustion engine, comprising the steps of:

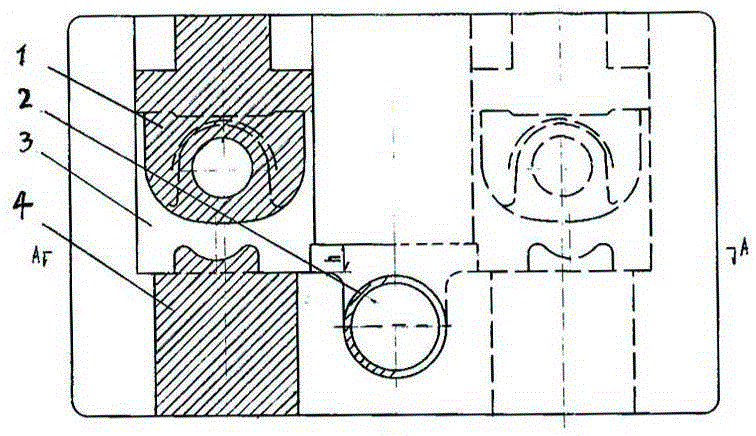

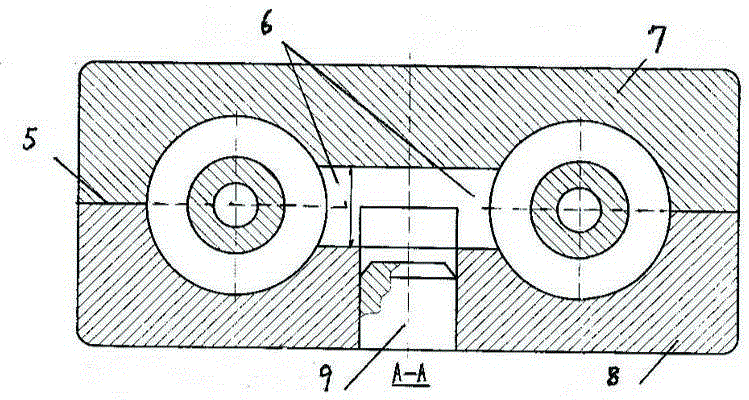

[0018] (1) Design and produce such as figure 1 , figure 2 The mould, which adopts H13 or 3Cr2W8V alloy steel, consists of a moving mold body 7, a static mold body 8, an upper core 1, a lower core 4, a piston cavity 3, an injection chamber 2 and an injection head 9; The shape of the gate of the piston cavity is an arc gate 6 similar to the shape of the piston. The length L of the gate is 1 / 2 of the diameter of the cast piston, and the height h of the gate is the height of the head of the cast piston. One-half of that; use the method of changing the diameter of the injection chamber to achieve the best compressive stress of 1100MPa-1300MPa required for the solidification of the molten aluminum in the most suitable piston cavity;

[0019] (2) Install the extrusion die: press the prepared extrusion die figure 2 As shown, it is installed on a horizontal cold chamber die-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com