Method for preventing conveying errors of filter rods for filter rod conveying machine

A transmitter and error prevention technology, applied in applications, special data processing applications, instruments, etc., can solve the problems of physical information verification, increase quality accidents, etc., and achieve the effect of preventing production accidents and quickly identifying and recording

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

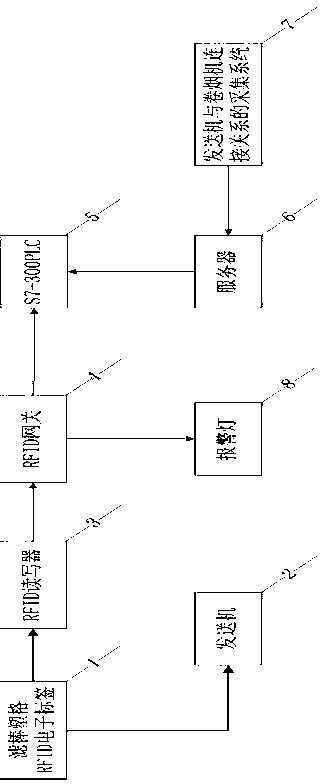

[0017] Such as figure 1 As shown, an anti-error device for filter rods includes filter rod plastic lattice RFID electronic label 1, transmitter 2, RFID reader-writer 3, RFID gateway 4, S7-300PLC5, server 6, and the connection system between the transmitter and the cigarette making machine Acquisition system7.

[0018] The filter rod plastic grid RFID electronic tag 1 is used to record the information of the filter rod material, including: material code, production machine, production shift, production shift, and production time. And the internal code of each electronic tag is unique.

[0019] The filter rod plastic grid RFID electronic tag 1 stops when it is transported to the transmitter 2 by a belt, and the RFID reader 3 installed on the transmitter 2 automatically reads the filter rod plastic grid RFID electronic tag information 1. The RFID reader-writer 3 transmits the read information to the RFID gateway 4, and the RFID network 4 stores the received RFID tag informatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com