Suture reinforcing material being for use in automatic suturing devices and containing hydrophilic polymer

The technology of a hydrophilic polymer and automatic suture device is applied in the field of suture reinforcement materials to achieve the effect of reducing the risk of air leakage and the risk of tissue rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

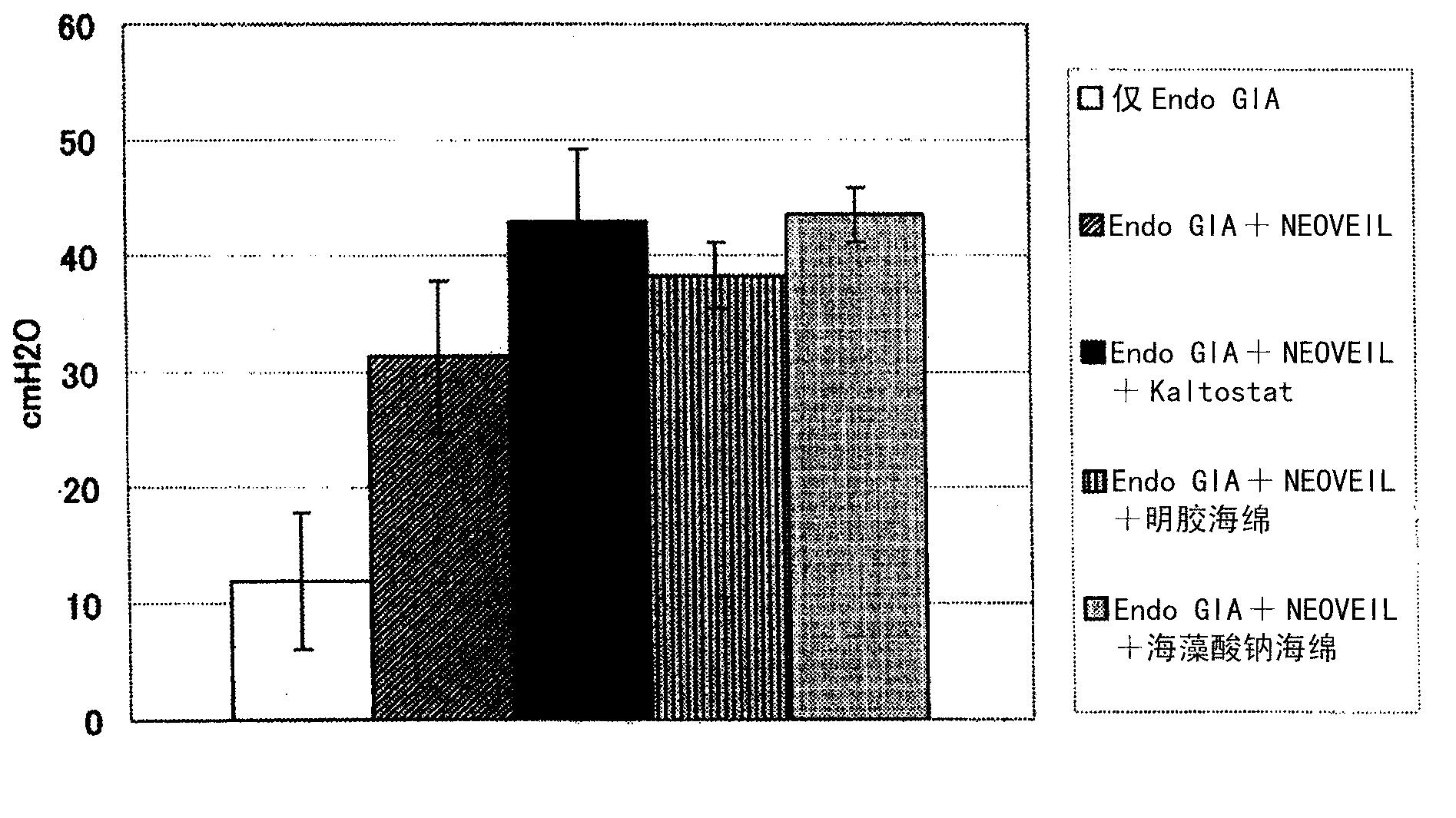

Embodiment 1

[0141] (1) Production of suture reinforcement materials for automatic suturers

[0142] The suture reinforcing material for an automatic suture device of the present invention was produced as follows.

[0143] [Production Method]

[0144] (i) A sheet that is a mixture of calcium salt and sodium salt of alginic acid ("Kaltostat" (registered trademark); Convatec Japan K.K.; hereinafter, also referred to as "alginic acid-Ca / Na salt sheet.") is cut Into a 3.5 × 7cm square.

[0145] (ii) A 2% sodium alginate solution was applied to the entire circumference of the cut alginic acid-Ca / Na salt sheet.

[0146] (iii) The alginic acid-Ca / Na salt sheet coated with a 2% sodium alginate solution was frozen at -80°C, and then dried with a freeze dryer to form a sponge (porosity).

[0147] (iv) A spongy alginic acid-Ca / Na salt sheet was superimposed on a felt made of polyglycolic acid ("NEOVEIL" (trade name); GUNZE Co., Ltd.) cut into approximately the same size.

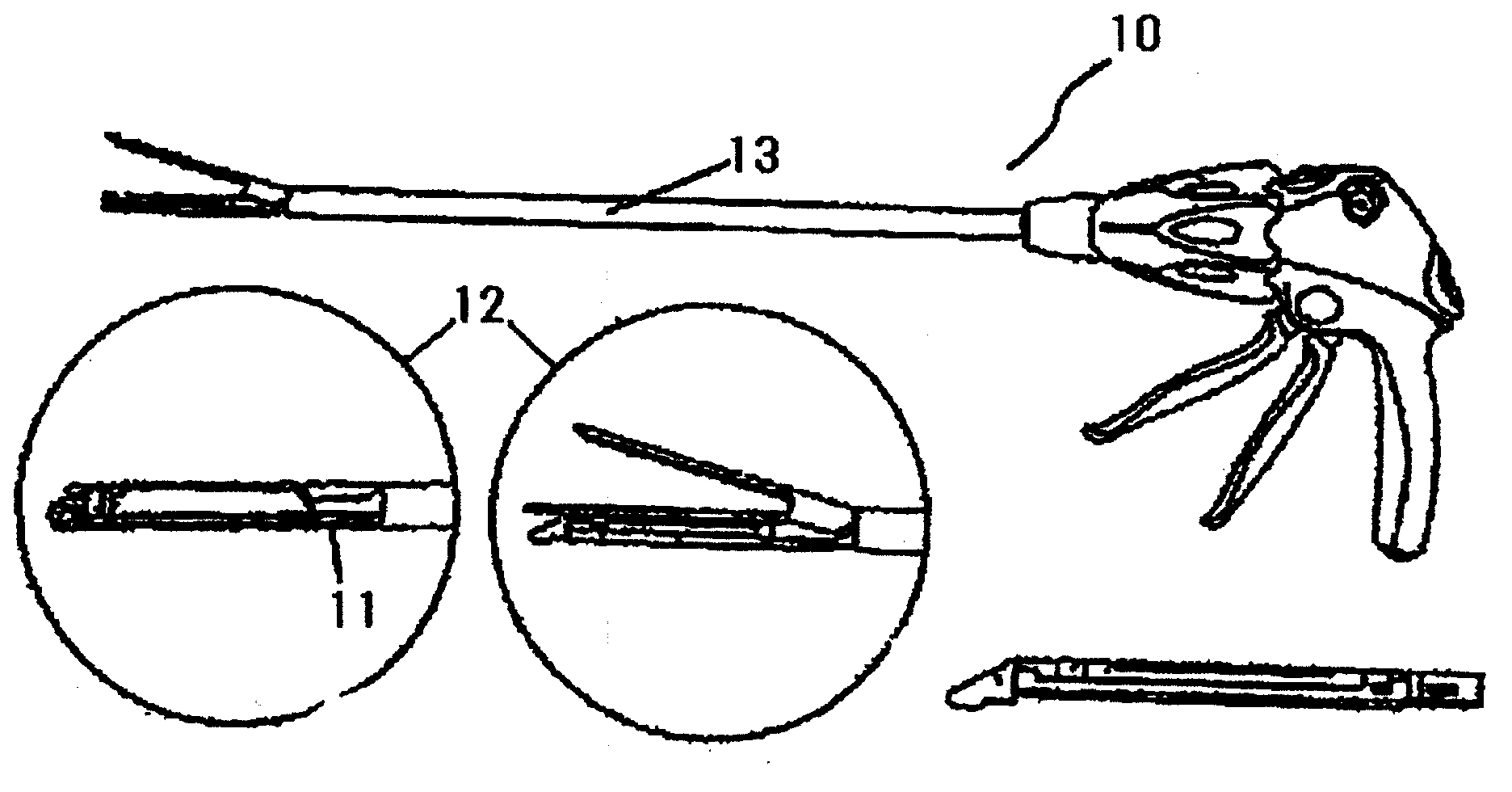

[0148] (2) Suturing...

Embodiment 2

[0166] (1) Production of suture reinforcement materials for automatic suturers

[0167] The suture reinforcing material for an automatic suture device of the present invention was produced as follows.

[0168] [Production Method]

[0169] (i) Sodium alginate aqueous solution (2%, 10mL) was poured into a plastic tray (5.3×8.3cm 2 ).

[0170] (ii) Freezing at -80°C.

[0171] (iii) Load into a freeze dryer, and carry out vacuum freeze drying (24 hours).

[0172] (iv) Cut the resulting sponge into 3.5 x 7.0 cm squares.

[0173] (v) A sponge-formed sodium alginate sheet was superimposed on a felt made of polyglycolic acid ("NEOVEIL" (trade name); GUNZE Co., Ltd.) cut into approximately the same size.

[0174] (vi) The neoveil part of the Neoveil tube type (manufactured by GUNZE Co., Ltd.) was replaced with the sheet-like material produced above to produce the suture reinforcing material for automatic suturing device of the present invention. Specifically, cut the sheet mate...

Embodiment 3

[0180] (1) Production of suture reinforcement materials for automatic suturers

[0181] The suture reinforcing material for an automatic suture device of the present invention was produced as follows.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com