Touch screen and production method thereof

A manufacturing method and touch screen technology, which are applied in the fields of instruments, electrical digital data processing, and data processing input/output processes, can solve the problems of complex manufacturing process and high cost, and achieve the effect of simplifying the manufacturing process, low cost, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in combination with the accompanying drawings and specific embodiments.

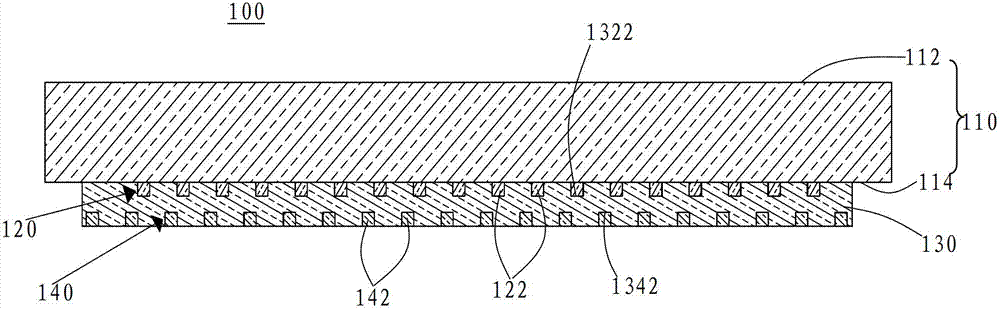

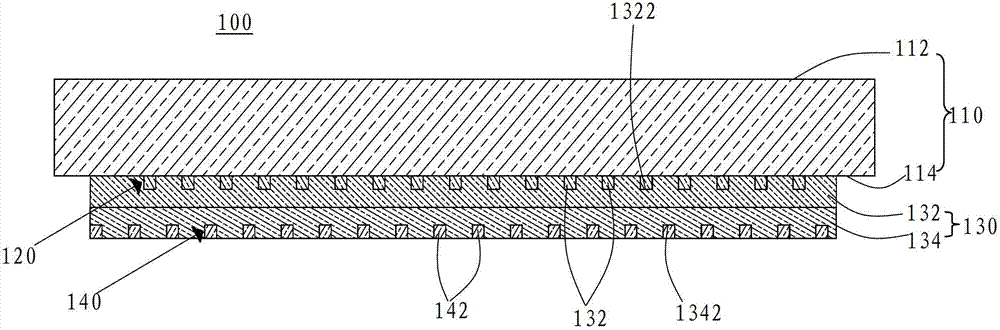

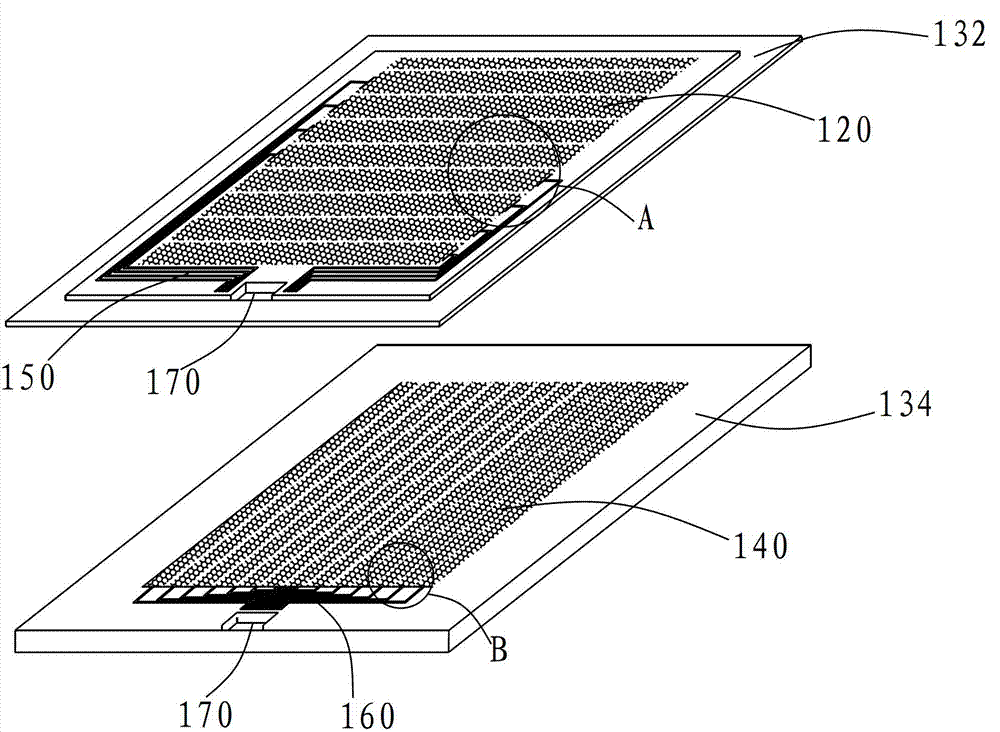

[0043] see figure 1 , a touch screen 100 comprising a glass substrate 110 , a first conductive layer 120 , an insulating glue layer 130 and a second conductive layer 140 . The glass substrate 110 includes a first surface 112 and a second surface 114 , and the first surface 112 and the second surface 114 are disposed opposite to each other. The metal coating is formed by electroless plating, electroplating, vacuum sputtering or vapor deposition, and then the metal coating is patterned and etched to obtain the first conductive layer 120 directly attached to the surface of the glass substrate 110 . The first conductive layer 120 includes a plurality of first conductive pattern regions 122 , the first conductive pattern regions 122 include a metal grid formed by crossing metal lines, and the plurality of first conductive pattern regions 122 are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com