Universal device of initial breaking of structural member of structural coherence collapse experiment

A technology of structural components and general devices, which is applied in the field of progressive collapse test research and the field of general devices for the initial fracture of structural components in progressive collapse experiments, which can solve problems such as impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. The components of this device

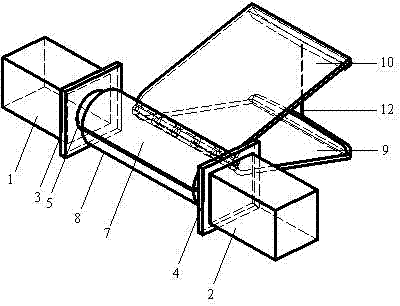

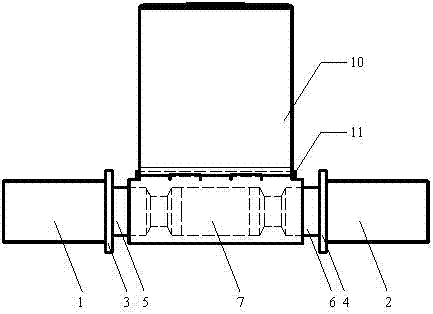

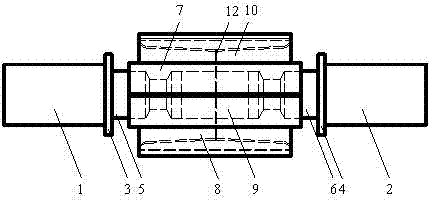

[0025] Figure 1-Figure 6 , Figure 7 (a) and Figure 7 (b) is the view and schematic diagram of each direction of the present invention (including the intended breaking member installed with the device). The present invention consists of 3 main components:

[0026] ① Two double-slope steel heads and steel head connecting end plates (left end plate 3 in the figure, right end plate 4, left double-slope steel head 5 and right double-slope steel head 6); left double-slope steel The head 5 is welded to the left end plate 3, and the other side of the left end plate 3 is fixed to the left part 1 of the component to be broken by welding or fastener connection, and the right double-slope steel head 6 is connected to the right end plate 4 Welding connection, the other side of the right end plate 4 is fixed to the left part 2 of the component to be broken by means of welding or fastener connection;

[0027] ② The scissor clamp hoop consists...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com