Dye monomer and preparation method and application thereof, and chromatic polymer emulsion and preparation method and application thereof

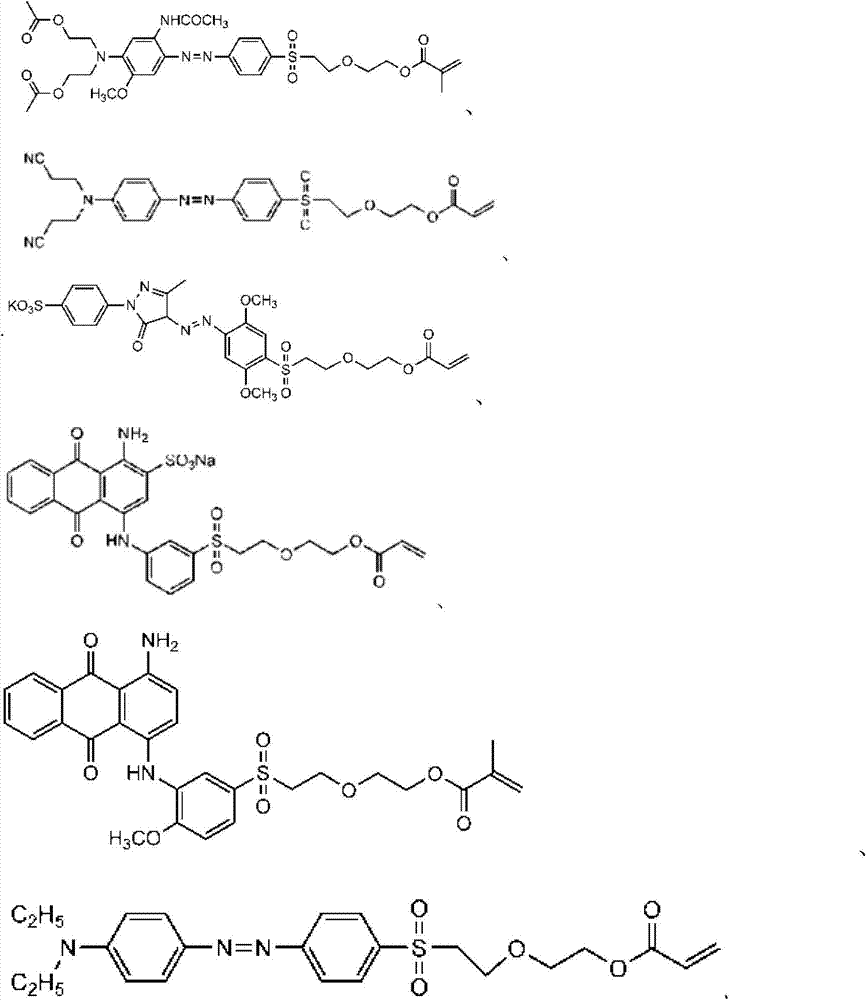

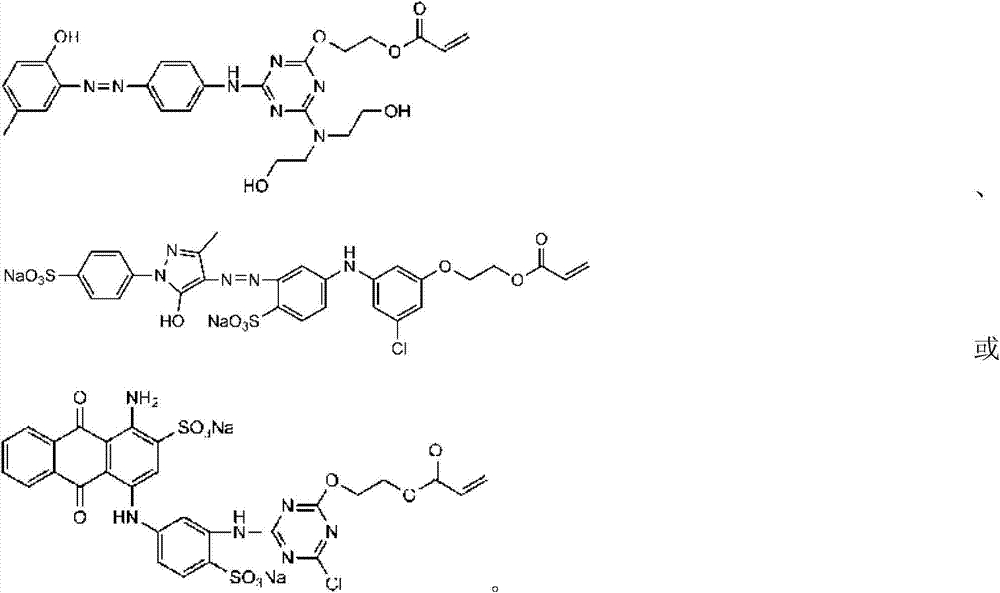

A technology of dye monomers and monomers, applied in the fields of application, reactive dyes, azo dyes, etc., which can solve the problems of preparing covalently bonded colored polymer emulsions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

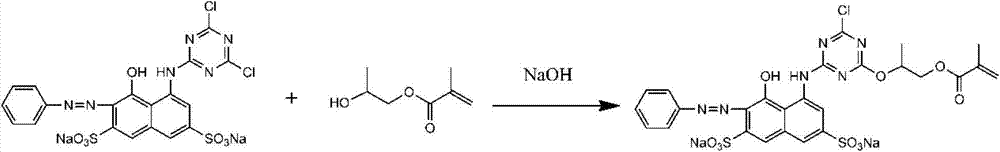

[0070] The preparation of embodiment 1, red dye monomer (I)

[0071] 6.15 grams of reactive dye reactive brilliant red X-3B (615g / mol), 30 grams of organic solvent tetrahydrofuran and 7.2 grams of double bond functionalization reagent hydroxypropyl methacrylate are added in the there-necked flask, and then 0.8 grams of mass percent concentration is added. 10% aqueous solution of accelerator sodium hydroxide, stirred and mixed and heated up to 60°C, replaced for 8 hours, added 400 ml of water to the flask after completion, filtered after standing, washed the filter cake with water until the filtrate was colorless, collected the filtered Cake, after drying, the red dye monomer (I) was obtained.

[0072] The reaction equation of above-mentioned preparation dye monomer is as follows:

[0073]

Embodiment 2

[0074] The preparation of embodiment 2, red polymer emulsion (I) (method one)

[0075] 1) Prepare gained red dye monomer (I) with 0.4 gram embodiment 1, 1.5 gram cross-linking monomer diacetone acrylamide, 0.3 gram main monomer methacrylic acid, 19 gram main monomer styrene and 19 gram main monomer Bulk butyl acrylate was mixed and stirred to fully dissolve to obtain mixed monomers.

[0076] 2) Dissolve 0.3 g of initiator ammonium persulfate in 10 milliliters of water to obtain an aqueous solution of initiator ammonium persulfate.

[0077] 3) Mix 6 grams of mixed monomers obtained in step 1), 50 milliliters of water, 0.3 grams of emulsifier nonylphenol polyoxyethylene ether (OP-10), 0.6 grams of emulsifier sodium lauryl sulfate and 0.15 grams of buffer carbonic acid Add ammonium hydrogen into the three-necked flask, stir and mix, and when the temperature rises to 70°C, add 4 ml of the aqueous solution of ammonium persulfate obtained in step 2) to the system, start timing from...

Embodiment 3

[0079] Embodiment 3, the preparation of red dye monomer (II)

[0080] Add 6.66 grams of reactive disperse red GR (666g / mol) reactive dyes, 30 grams of dimethyl sulfoxide organic solvent and 6.5 grams of hydroxyethyl methacrylate double bond functionalization reagent into the one-mouth bottle, then add 1.59 grams of mass percent Concentration is 20% saturated aqueous solution of sodium carbonate promoter, stir and mix and heat up to 70 ° C, replace reaction for 12 hours, add a large amount of water to the flask after the end, filter after standing, wash the filter cake with water until the filtrate is colorless, collect The filter cake was dried to obtain the red dye monomer (II).

[0081] The reaction equation of above-mentioned preparation dye monomer is as follows:

[0082]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com