Rubber Composition For Tire, And Pneumatic Tire

A rubber composition, a technology for pneumatic tires, applied in special tires, tire parts, wheels, etc., can solve the problems of changing the resistance time of carbon black dispersion tires and other problems, and achieve excellent fuel economy, prevent The effect of static electricity accumulation, excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0087] Here, it is more preferable that the rubber composition is produced by a production method further comprising a re-kneading step of re-kneading the kneaded product obtained by the basic kneading step 2 before the final kneading step . By carrying out the re-kneading step, the dispersibility of carbon black can be further improved and fuel economy and durability can be further improved, as well as contributing to suppression of an increase in tire resistance over time.

[0088] In the rubber composition, the dispersion ratio (measured by the SPM method) of carbon black in the phase of the diene rubber having the highest SP value is preferably 1 or more. Furthermore, the dispersion ratio thereof is preferably 5 or less, more preferably 3 or less, even more preferably 2 or less, and particularly preferably 1.5 or less. When the dispersion ratio thereof is within the above range, it indicates that the carbon black is well dispersed in the rubber composition containing two ...

Embodiment

[0213] The present invention is described in detail by way of examples, but the present invention is not limited thereto.

[0214] Various chemicals used in Examples and Comparative Examples are summarized below.

[0215]

[0216] NR (Natural Rubber): RSS#3 (SP value: 7.9)

[0217] BR (butadiene rubber): BR150B manufactured by Ube Industries, Ltd. (cis content: 95% by mass, SP value: 8.4)

[0218] ENR25 (epoxidized natural rubber): ENR25 (epoxidized natural rubber having a degree of epoxidation of 25 mol %, SP value: 9) produced by Kumpulan Guthrie Berhad (Malaysia)

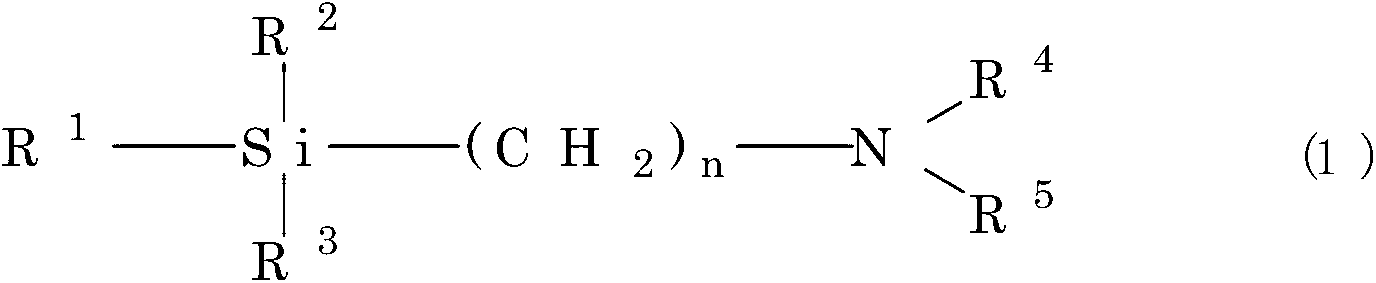

[0219] SBR: HPR340 produced by Nippon Synthetic Rubber Co., Ltd. (modified S-SBR, styrene binding amount: 10% by mass, Tg: -60°C; coupled with alkoxysilane and terminated, and a compound represented by formula (1) Modification; SP value: 8.1)

[0220] Silica: Ultrasil VN3 (N 2 SA: 175m 2 / g)

[0221] Silane coupling agent: Si69 (bis(3-triethoxysilylpropyl) tetrasulfide) produced by Degussa

[0222] Carbo...

Embodiment and comparative example 8

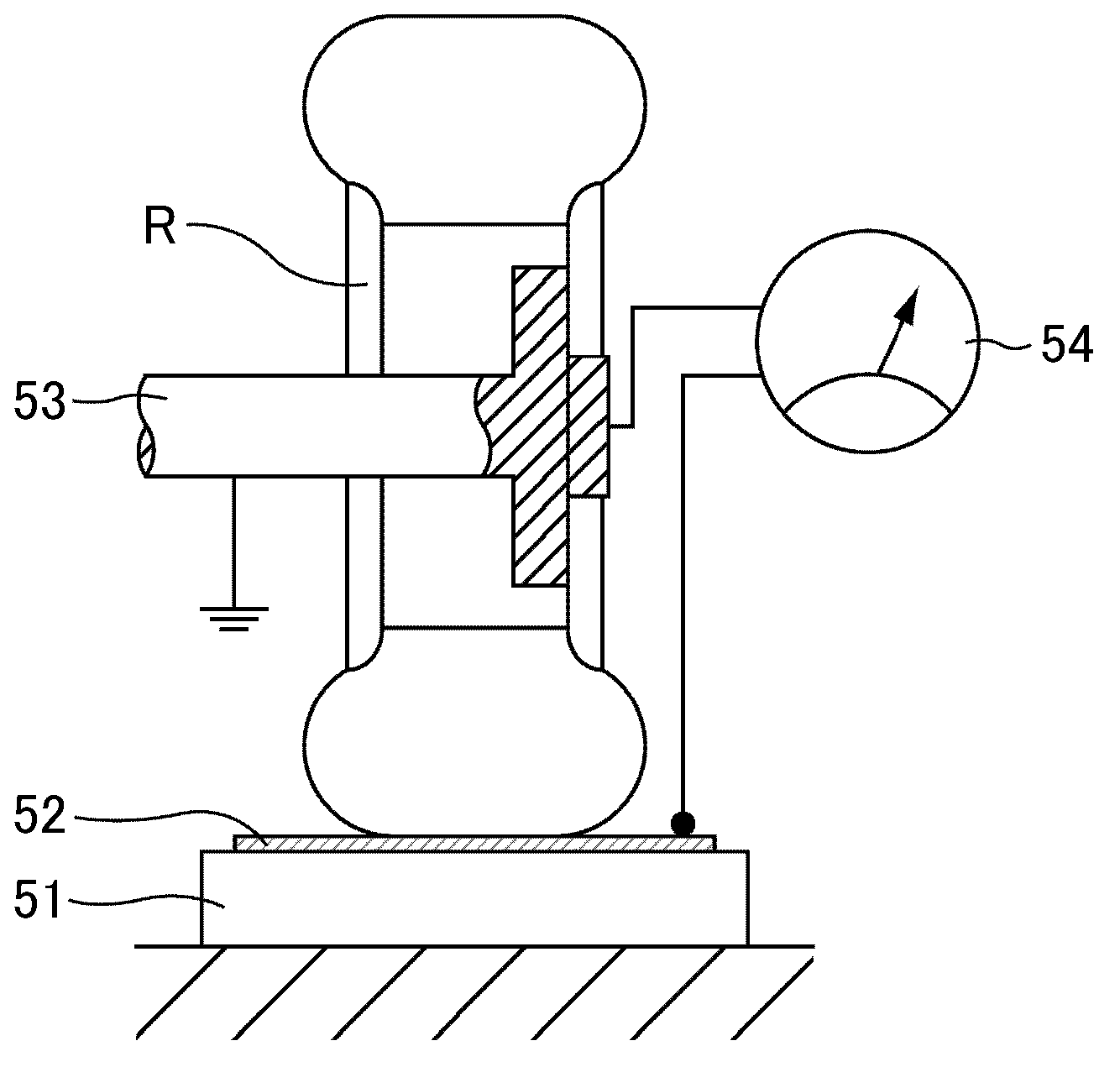

[0242] Of the mixed components shown in Table 1, the components shown in step 1 were kneaded for 4 minutes using a Banbury mixer so that the discharge temperature (Discharge temperature) was 150° C. (basic kneading step 1). Thereafter, the kneaded product obtained by the basic kneading step 1 and the components shown in step 2 were kneaded for 3 minutes using a Banbury internal mixer so that the discharge temperature was 150° C. (basic kneading step 2). In addition, in Examples 3 to 6 and Comparative Example 8, the kneaded material obtained in the basic kneading step 2 was kneaded for 3 minutes using a Banbury internal mixer so that the discharge temperature was 140° C. (the re-kneading step ). Subsequently, sulfur and a vulcanization accelerator were added to the kneaded product obtained by the basic kneading step 2 or the kneaded product obtained by the re-kneading step, and the obtained kneaded product was further kneaded for 3 minutes to discharge The temperature was 100°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com