Air-flowing type tobacco shred perfuming device

A flavoring device and air-flow technology, which is applied in the field of cut tobacco processing, can solve the problems of limited throwing space, short flavoring area, uneven flavoring, etc., achieve uniform spraying and absorption, avoid damage, and avoid loss of spices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

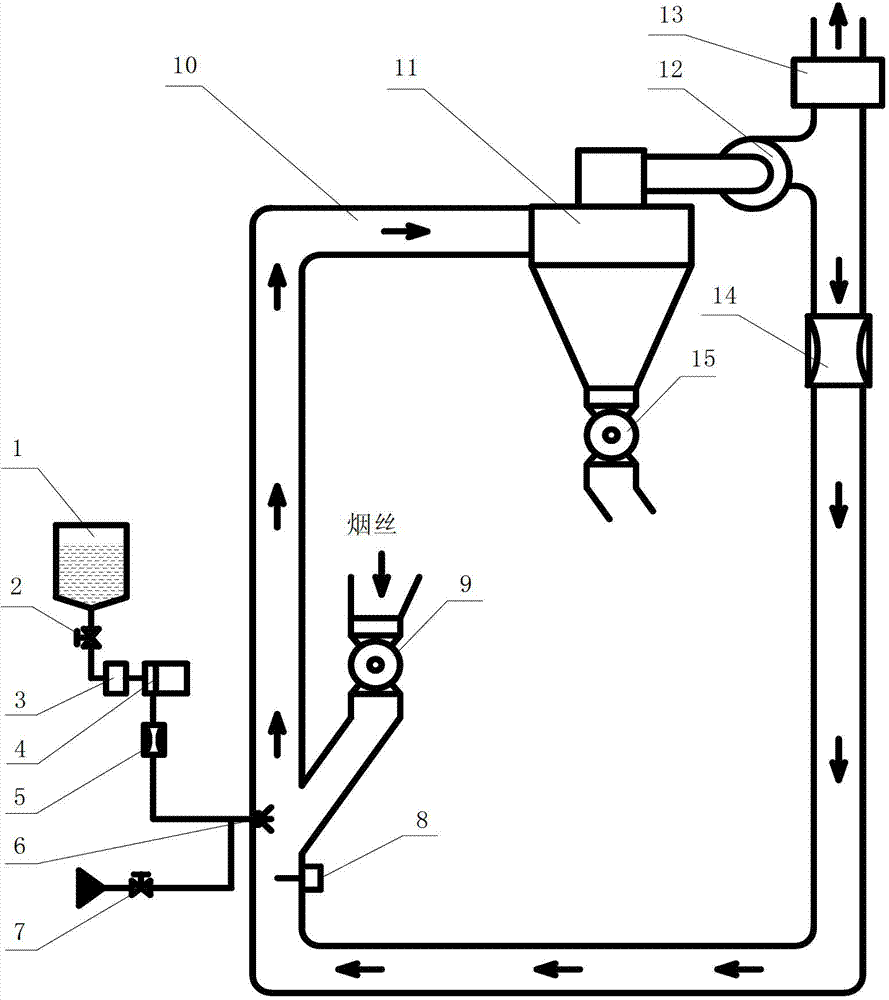

[0015] like figure 1 As shown, the present invention includes a spice tank 1, a feed liquid solenoid valve 2, a filter 3, a pump 4, a nozzle 6 and an air compression device 7, and the spice tank 1 passes through the feed liquid solenoid valve 2, the filter 3, the pump 4 and the nozzle 6 Pipeline connection, air compression device 7 and nozzle 6 pipeline connection, also includes feed air lock 9, process gas pipeline 10, cyclone blanker 11, circulation fan 12, exhaust damper 13 and discharge air lock 15, nozzle 6. The feed air lock 9 is fixed on the process gas pipeline 10, and the exhaust damper 13 is installed on the process gas pipeline 10. One end of the process gas pipeline 10 is connected to the circulating fan 12, and the other end is connected to the cyclone blanking device 11. The feeder 11 is connected with the circulating fan 12, and the discharge air lock 15 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com