Production process intelligent control system and method

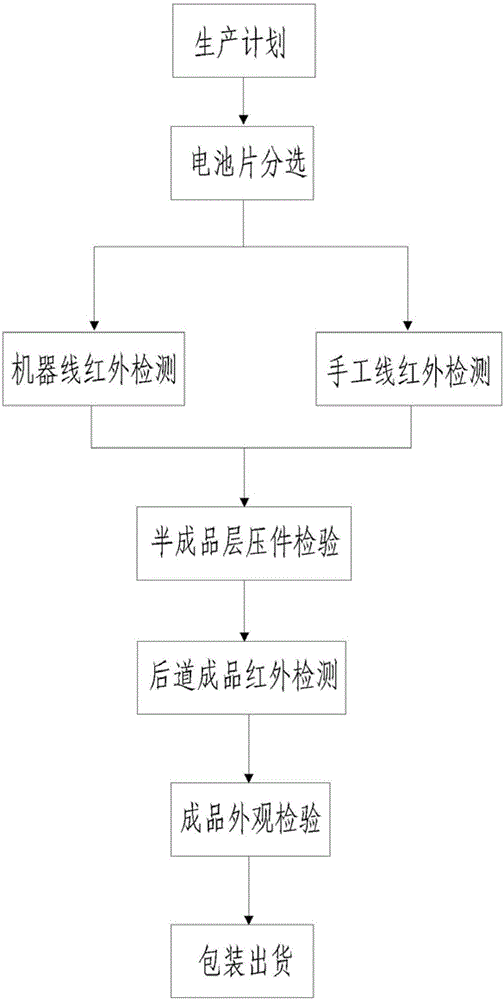

A production process and intelligent technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of repeated ID numbers, artificial inability to check and find ID numbers in time, troublesome product quality and sales, etc., to achieve improvement The effect of life and completeness, eliminating duplication of ID numbers, and facilitating traceability and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific drawings and embodiments.

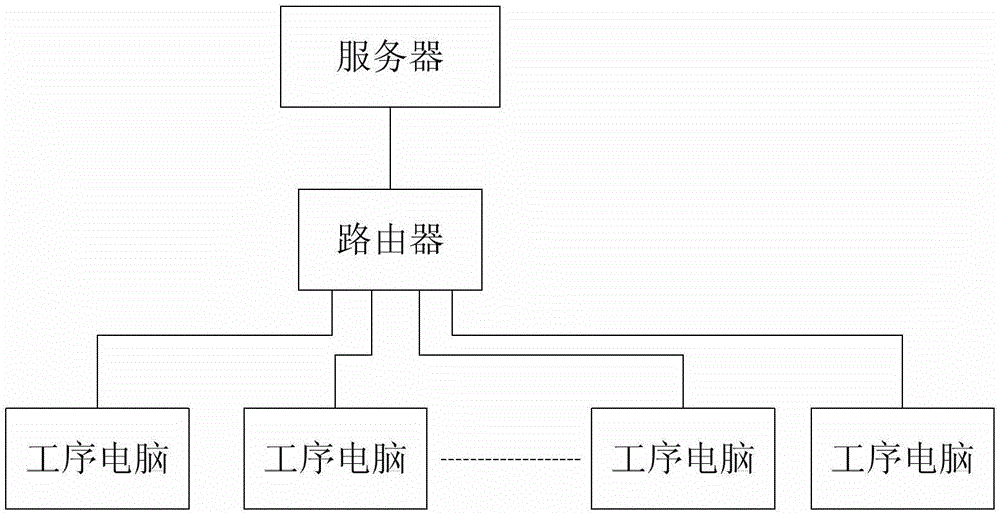

[0028] The production process intelligent management and control system includes two parts: hardware system and software system. The hardware system includes one or more process computers corresponding to each production process. The process computers are connected to the server through a router to form a local area network; a platform can be provided for the operation of the software system.

[0029] figure 1 The structure of the local area network is given. The server is connected to the router through the network cable, and the other process computers in the local area network are also connected to the router through the network cable, so that all the process computers can access the server. For each production process, a corresponding process computer is configured.

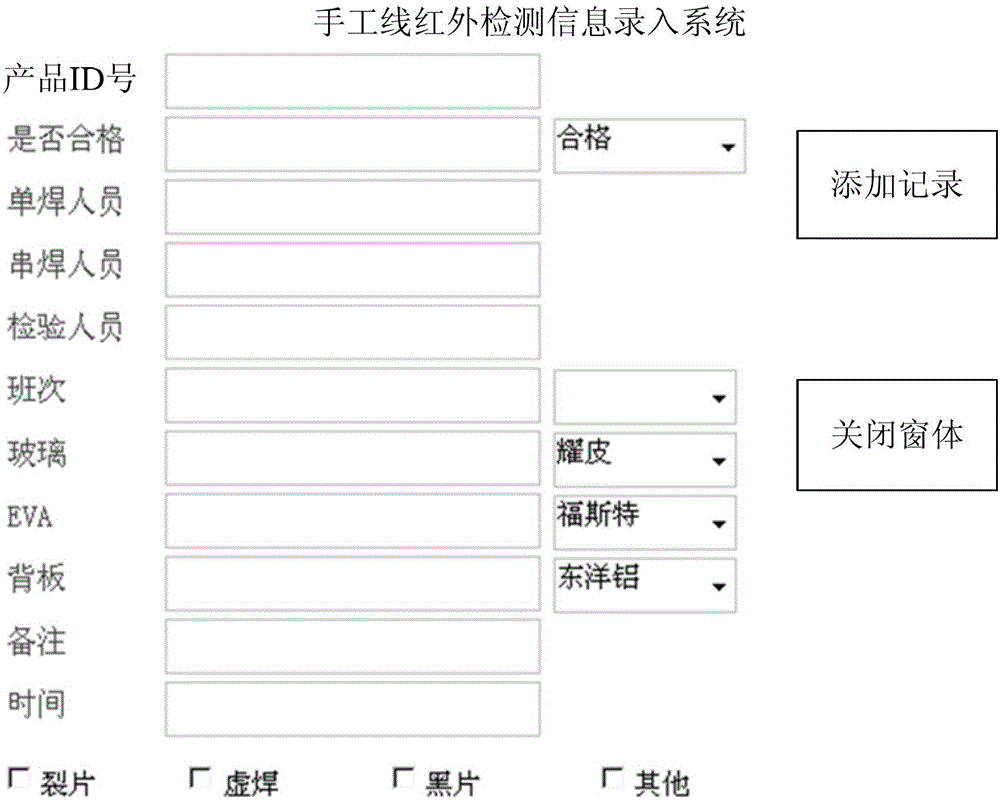

[0030] The software system uses VB language to develop based on ACCESS software programm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com