Main shaft-knife handle joint surface nonlinear dynamic characteristic parameter identification method

A nonlinear dynamic and characteristic parameter technology, applied in vibration testing, testing of machine/structural components, measuring devices, etc., to solve problems such as nonlinearity of the spindle-tool holder system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

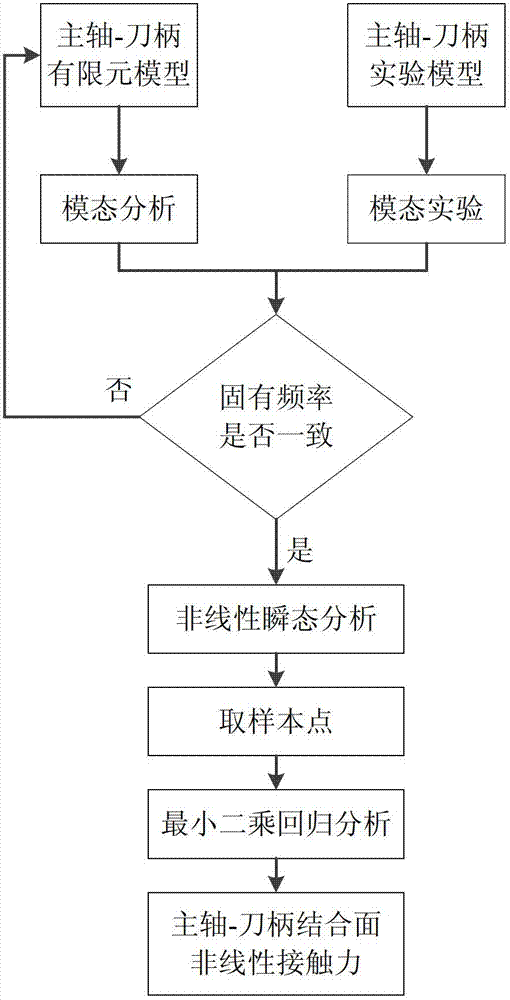

[0042] Such as figure 1 As shown, a method for identifying the nonlinear dynamic characteristic parameters of the spindle-tool holder joint surface includes the following steps:

[0043] (1) The finite element analysis model of the spindle-knife holder is established by using the finite element analysis software; in this embodiment, the finite element analysis model of the spindle-knife holder is established by using the Hyper Works finite element analysis software.

[0044](2) Check whether the spindle-tool holder finite element analysis model is correct, if it is confirmed, go to step (4), if it is confirmed that there is a difference, go to step (3);

[0045] In this embodiment, step (2) specifically includes the following steps:

[0046] (a) Perform free modal analysis on the finite element analysis model of the spindle-tool holder, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com