Novel difunctional ultraviolet luminescent material having long afterglow and mechanoluminescence

A luminescent material and stress luminescence technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems that the luminous intensity does not meet the requirements of the application, and the types of stress luminescent materials are scarce.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

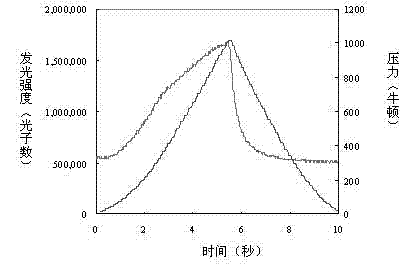

[0008] Take Sr 1.98 MgSi 1.95 al 0.05 o 6 : Ce 0.01 , Dy 0.01 As an example, it is synthesized by a typical solid-state synthesis method. About to analyze pure SrCO 3 , MgO, SiO 2 、Al 2 o 3 , CeO 2 、Dy 2 o 3 After adding ethanol according to the molar ratio for thorough grinding and mixing, pre-fired at 800°C for 2 hours, then fully ground, put it into an atmosphere furnace and roast at 1200°C for 4 hours in a hydrogen atmosphere to obtain the required sample. The resulting samples were tested for fluorescence properties (see attached figure 1 , figure 2 ), the results show that the developed sample has a strong luminescence at 347nm, and the afterglow can last for 3 hours. Mix the obtained luminescent powder sample with high elastic resin (mass ratio 1:3) to prepare a rectangular module (4X2X2cm). And use the self-made instrument to carry out stress luminescence test on it, the result (see image 3 ) shows that the stress luminescence wavelength is consistent...

Embodiment 2

[0010] According to the chemical formula Sr 1.98 MgSi 1.95 Ga 0.05 o 6 : Ce 0.01 ,La 0.01 Accurately weigh analytically pure SrCO by molar ratio 3 , MgO, SiO 2 , Ga 2 o 3 , CeO 2 , La 2 o 3 After adding ethanol for thorough grinding and mixing, pre-fire at 800 degrees for 2 hours, then fully grind, put into the hydrogen atmosphere of the atmosphere furnace (H 2 / Ar) at 1200°C for 4 hours to obtain the desired sample. The obtained sample was tested for fluorescence performance, and the results showed that the developed sample had a strong luminescence at 347nm, and the afterglow could last for 3.5 hours. Mix the obtained luminescent powder sample with high elastic resin (mass ratio 1:3) to prepare a rectangular module (4X2X2cm). And use the autonomous instrument to carry out the stress luminescence test, the results show that the stress luminescence wavelength is consistent with the photoluminescence wavelength, located at 347nm, and has a high sensitivity to stres...

Embodiment 3

[0012] According to the chemical formula Sr 1.98 MgSi 1.95 B 0.05 o 6 : Ce 0.01 ,Ho 0.01 Accurately weigh analytically pure SrCO by molar ratio 3 , MgO, SiO 2 、B 2 o 3 , CeO 2 、Ho 2 o 3 After adding ethanol for thorough grinding and mixing, pre-fire at 800 degrees for 2 hours, then fully grind, put into the hydrogen atmosphere of the atmosphere furnace (H 2 / Ar) at 1200°C for 4 hours to obtain the desired sample. The obtained sample was tested for fluorescence performance, and the results showed that the developed sample had strong luminescence at 347nm, and the afterglow could last for 3 hours. The same stress luminescence performance test shows that the prepared samples have high stress luminescence performance (1000N, 2.1×10 6 cps).

[0013] The functional ultraviolet luminescent material in the present invention has the following superior properties:

[0014] 1. It has high stress luminous performance, under the action of low mechanical force (1000N), its st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com