Anti-tear EVA (ethylene-vinyl acetate copolymer) foaming shoe material and preparation method thereof

A manufacturing method and tear-resistant technology, applied in the field of leisure shoe soles, can solve the problems of increased design space, easy breakage, poor tear resistance, etc., and achieve the effects of increased design space, wearing safety, and excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

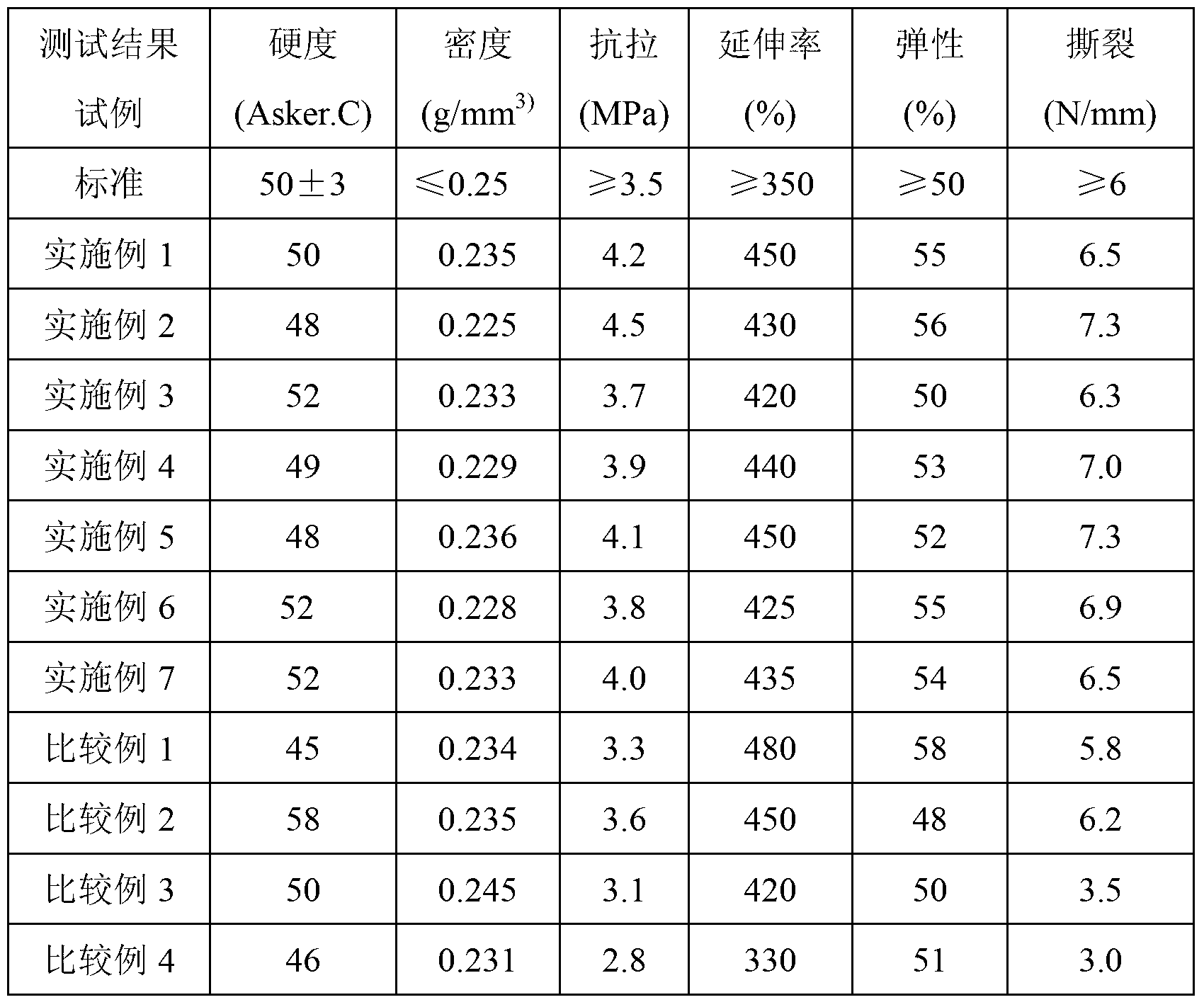

Examples

Embodiment 1

[0046] Embodiment 1: The preparation method of the tear-resistant EVA foam shoe material of the present invention comprises the following steps.

[0047] 1. The composition of raw materials by mass percentage is as follows:

[0048] Ethylene-vinyl acetate copolymer ELVAX260: 60%;

[0049] Ethylene-octene copolymer POE8842: 20%;

[0050] Hydrogenated styrene-butadiene-styrene block copolymer SEBS: 6%;

[0051] Ethylene-acrylic acid copolymer N493: 1.0%;

[0053] Stearic acid: 0.4%;

[0056] Dicumyl peroxide: 0.8%;

[0057] Azodicarbonamide: 2.0%;

[0058] Masterbatch: 2.0%.

[0059] 2. the manufacture method of described tear-resistant EVA foam shoe material is characterized in that comprising the following steps:

[0060] 1) Pound material

[0061] Weigh the raw materials according to the designed formula, after weighing the dicumyl peroxide and azo blowing agent separately, mix the t...

Embodiment 2

[0074] Embodiment 2: adjust the consumption of ELVAX260, POE8842, SEBS, N493 on the basis of embodiment 1, its raw material formula is as follows:

[0075] Ethylene-vinyl acetate copolymer ELVAX260: 55%;

[0076] Ethylene-octene copolymer POE8842: 25%;

[0077] Hydrogenated styrene-butadiene-styrene block copolymer SEBS: 5%;

[0078] Ethylene-acrylic acid copolymer N493: 1.5%;

[0080] Stearic acid: 0.3%;

[0082] Zinc oxide: 0.9%;

[0083] Dicumyl peroxide: 0.8%;

[0084] Azodicarbonamide: 2.0%;

[0085] Masterbatch: 2.0%.

Embodiment 3

[0086] Embodiment 3: On the basis of embodiment 2, continue to adjust the consumption of ELVAX260, POE8842, SEBS, N493, make it be controlled in the setting dosage range, its raw material formula is as follows:

[0087] Ethylene-vinyl acetate copolymer ELVAX260: 65%;

[0088] Ethylene-octene copolymer POE8842: 13%;

[0089] Hydrogenated styrene-butadiene-styrene block copolymer SEBS: 10%;

[0090] Ethylene-acrylic acid copolymer N493: 0.8%;

[0091] Talc powder: 5%;

[0092] Stearic acid: 0.4%;

[0093] Zinc stearate: 0.8%;

[0094] Zinc oxide: 1.0%;

[0095] Dicumyl peroxide: 0.8%;

[0096] Azodicarbonamide: 2.0%;

[0097] Masterbatch: 2.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com