Aqueous polymer solution with anti-mud or mud-resistance performances and preparation method thereof

An aqueous solution and polymer technology, applied in the field of polymer aqueous solution with mud resistance or mud resistance and its preparation, can solve the problems of fresh concrete slump or fluidity decrease, achieve novel molecular structure, improve anti-corrosion Mud or mud resistance, good mud resistance or mud resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

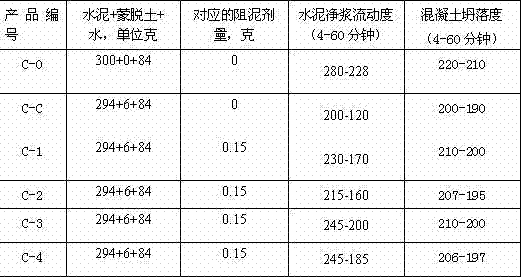

Examples

Embodiment 1

[0025] Monomer A 5g (hydroxypropyl acrylate)

[0026] Monomer B 50g (methacryloyloxyethyltrimethylammonium chloride DMC, 60% aqueous solution)

[0027] Put 60 g of deionized water into a four-necked flask, blow with nitrogen three times, and heat to 50°C with an oil bath. Add monomer A, B, chain transfer agent thioglycolic acid 0.33g and 30g deionized water mixture solution (1), 2g ammonium persulfate and 30g deionized water initiator aqueous solution (2) respectively. The two liquids were added dropwise at the same time, the dropwise addition time was 4 hours, the holding time was 4 hours, and the temperature was lowered to 50°C. An aqueous polymer solution with a content of 20% was obtained. It is recorded as anti-sludging agent C-1.

Embodiment 2

[0029] Monomer A 5g (hydroxypropyl acrylate) and 5g (hydroxypropyl acrylate)

[0030] Monomer B 50g (methacryloyloxyethyltrimethylammonium chloride DMC, 60% aqueous solution)

[0031] Put 75g of deionized water into a four-neck flask, blow with nitrogen three times, and heat to 60°C with an oil bath. Add monomer A, B, chain transfer agent mercaptopropionic acid 0.33g and 35g deionized water mixture solution (1), 2g ammonium persulfate and 40g deionized water initiator aqueous solution (2) respectively. The two liquids were added dropwise at the same time, the time for dropping was 3 hours, the holding time was 3 hours, and the temperature was lowered to 30°C. An aqueous polymer solution having a content of 40% was obtained. It is recorded as anti-sludging agent C-2.

Embodiment 3

[0033] Monomer A 15g (hydroxyethyl methacrylate)

[0034] Monomer B 25g (methacryloxyethyltrimethylammonium chloride DAC, 60% aqueous solution) and 25g dimethyldiallylammonium chloride (DADMAC)

[0035] Put 80 g of deionized water into a four-necked flask, blow with nitrogen three times, and heat to 70° C. with an oil bath. Add monomer A, B, chain transfer agent mercaptopropionic acid 0.33g and 35g deionized water mixture solution (1), 2g ammonium persulfate and 45g deionized water initiator aqueous solution (2) respectively. The two liquids were added dropwise at the same time, the dropwise addition time was 5 hours, the holding time was 5 hours, and the temperature was lowered to 30°C. An aqueous polymer solution having a content of 40% was obtained. It is recorded as anti-sludging agent C-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com