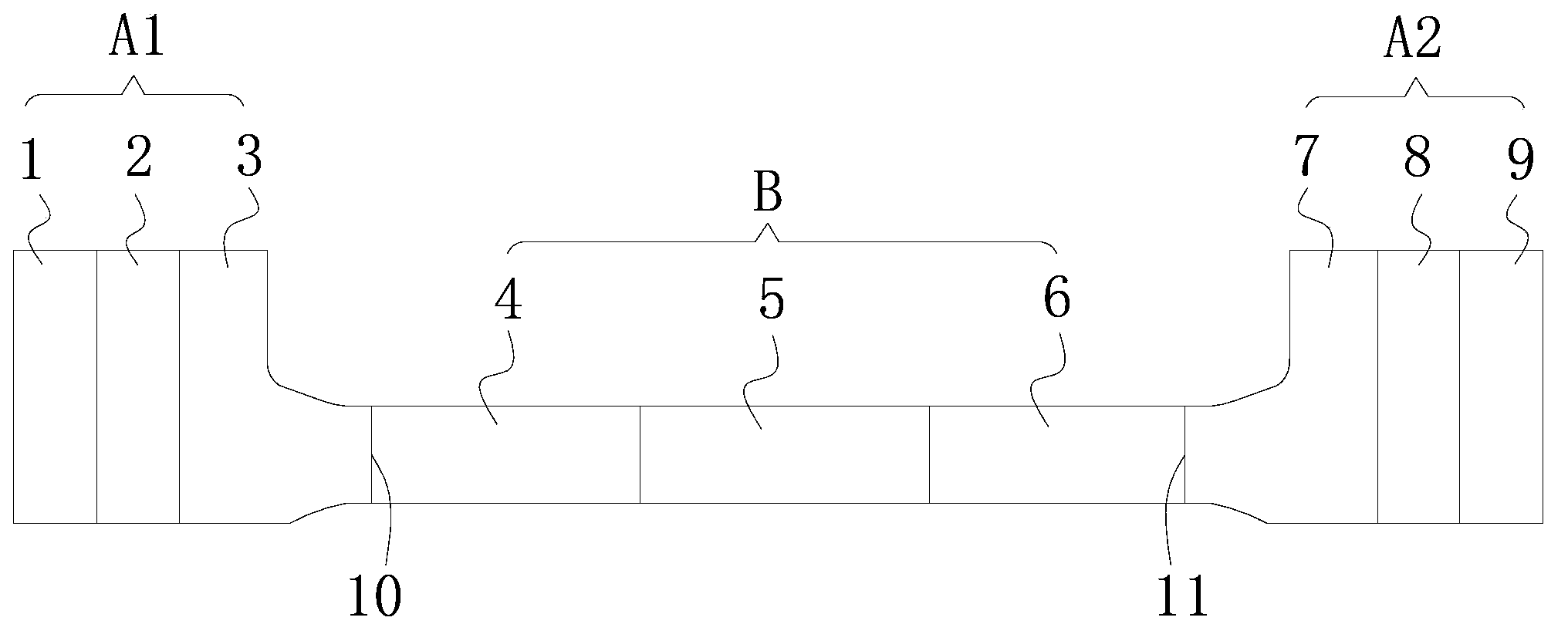

Vertical symmetrical welding method for wide and thick plates

A symmetrical welding, wide and thick plate technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of tight production cycle, unsuitable full-scale welding, and poor control of welding deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

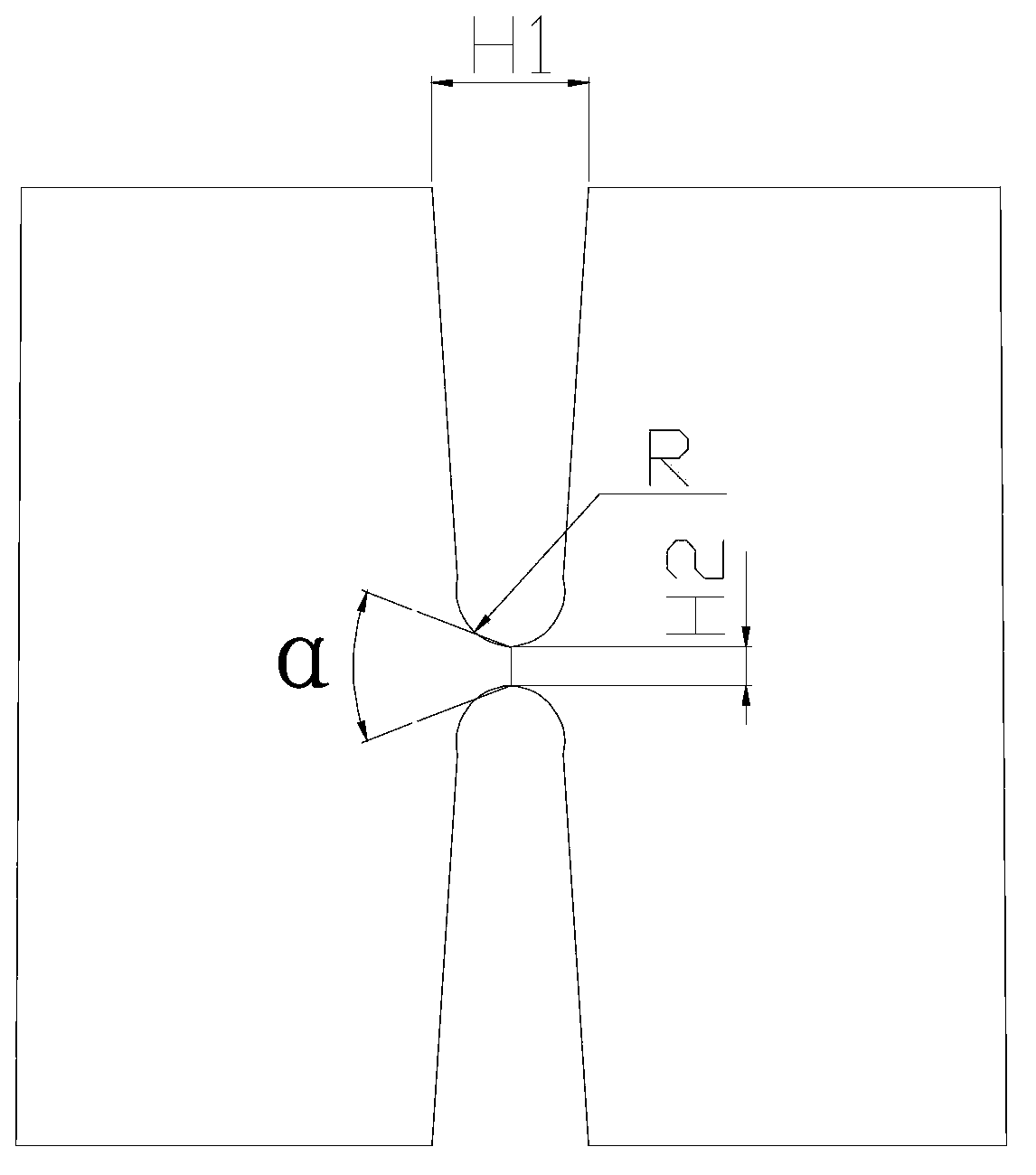

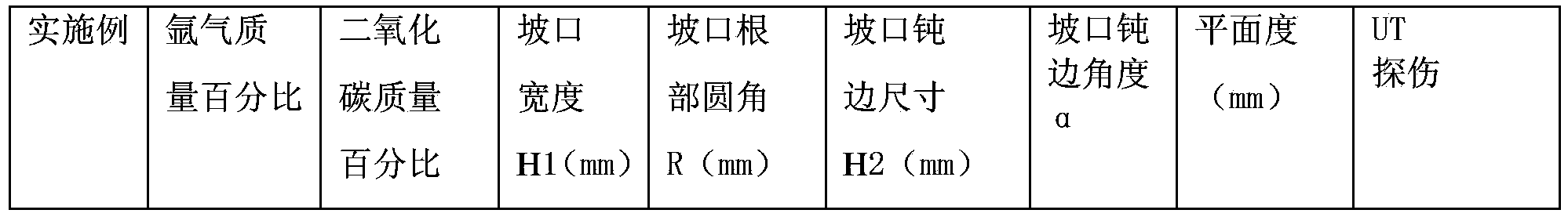

[0024] Use the above four steps of a, b, c, and d to weld the vertical plate. When proceeding to step d, use the parameters in the following table for welding. After the welding is completed, carry out flatness inspection and UT flaw detection to obtain the following The above test results:

[0025]

[0026]

[0027] In the 7 embodiments in the above table, it can be seen that when the mass percentage content of argon is 80%, the mass percentage content of carbon dioxide is 20%, the groove width is 18mm≤H1≤22mm, and the fillet at the root of the groove is When R=4mm, the size of the blunt edge of the groove is 2.5mm≤H2≤2.6mm, and the angle α of the blunt edge of the groove is 35°, the quality of the welded joint of the vertical plate is good, and the non-destructive testing is qualified, and the flatness can be well controlled at 0.2 mm; and when the width of the groove, the fillet R of the root of the groove, the size of the blunt edge of the groove, and the angle α of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com