Stone removing crusher

A technology of crusher and gravel, applied in grain processing and other directions, can solve the problems of easily damaged gravel rollers, high difficulty in replacement and assembly, and increased production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

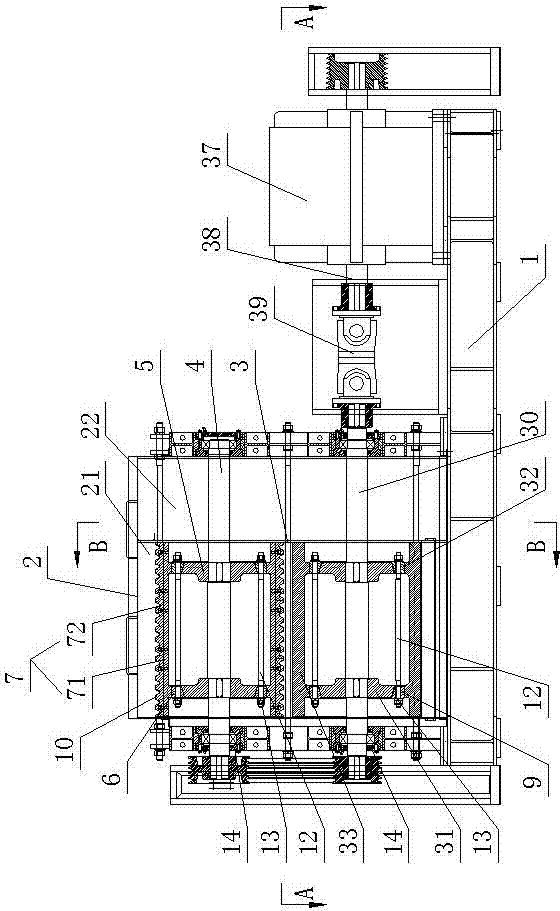

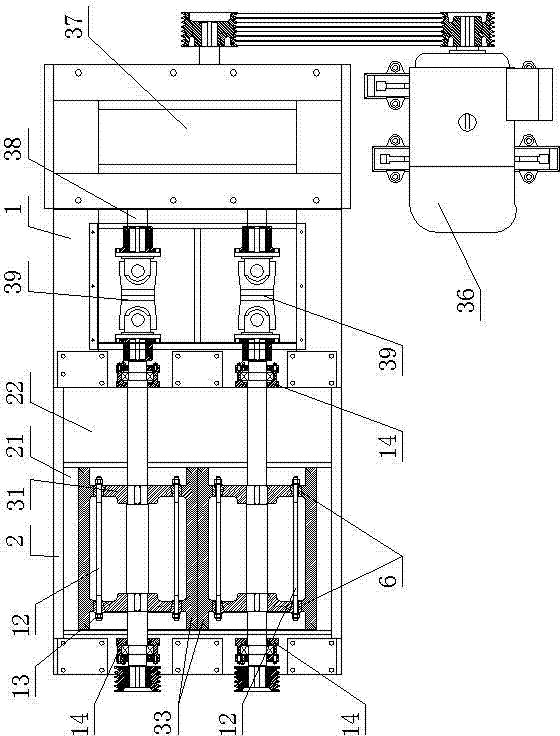

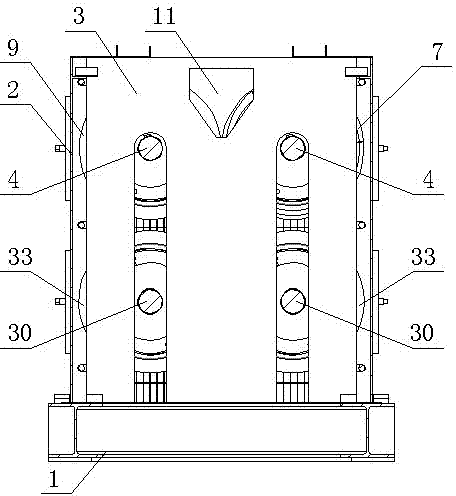

[0022] Such as figure 1 The stone removal crusher shown includes a frame 1, on which a stone removal and gravel bin 2 with a feed inlet is installed on the frame 1, and the stone removal and gravel bin 2 is surrounded by oppositely arranged side plates and passed through Fastened by the bolts, the stone removal bin 2 is equipped with a partition plate 3 that divides its inner cavity into a crushing chamber 21 and a tailing chamber 22. The bottoms of the crushing chamber 21 and the tailing chamber 22 are respectively provided with outlet The feed opening, the partition plate 3 is provided with a feed opening 11 connecting the upper part of the crushing chamber 21 and the tailing chamber 22, and the crushing chamber 21 is provided with a rotating connection on the wall of the stone removal chamber 2 and driven by a power device. For the two crushing shafts 4 rotating in opposite directions, the frame 1 is also equipped with a secondary crushing shaft 30 that is located below the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com