Gas dissolving device capable of combining pipe flow and vortex

A combined, pipe-flow technology, applied in fluid state mixers, grease/oily substance/float removal devices, dissolution, etc., can solve the problems of mechanical equipment maintenance, high maintenance cost, low dissolved gas efficiency, short water flow process, etc. problems, to achieve the effects of easy equipment maintenance, high dissolved air efficiency, and long water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

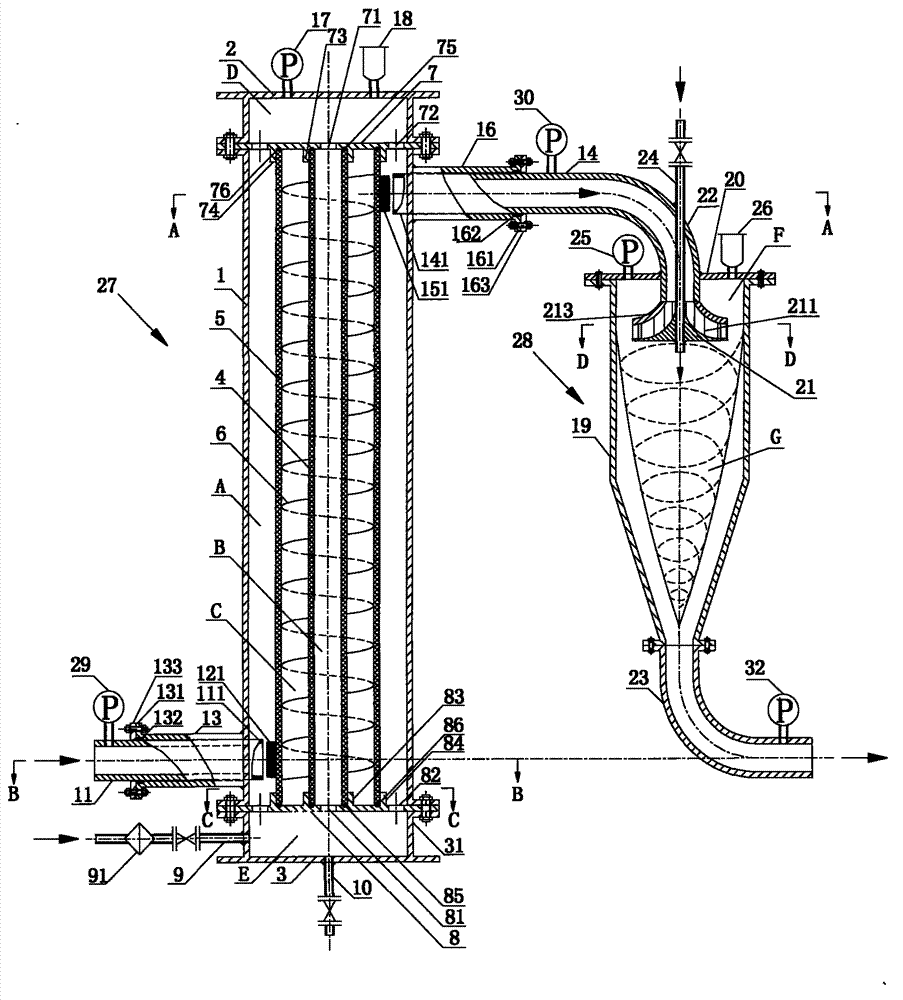

[0049] The air-dissolving device combining pipe flow and eddy current of the present invention can be used as high-efficiency air flotation and air-dissolving equipment for the treatment of oily wastewater and wastewater containing suspended solids, and the pipeline of the water to be treated is connected to the pipe flow tank through flanges or other methods The water inlet pipe 11 is connected to the dissolved air water pipe in the contact area of the air intake floating pool with the outlet pipe 23 of the vortex tank, and the compressed air pipe is connected, and then it can be put into use. The specific implementation is as follows:

[0050] Raw water flow 3m 3 / h, raw water emulsified oil 160mg / L, SS50mg / L.

[0051] Design process: water inlet → pipe flow dissolved air tank 27 → vortex dissolved air tank 28 → air flotation tank → water outlet.

[0052] Adopt the method of full-flow dissolving the waste water. After the waste water is pressurized by the booster pump, i...

Embodiment 2

[0055] The air dissolving device combined with pipe flow and eddy current of the present invention can be used as an integrated equipment for dissolving air and flocculation for the treatment of oily wastewater and wastewater containing suspended matter. Connect the pipeline of the water to be treated to the water inlet pipe 11 of the tube flow tank through flanges or other methods, connect the outlet pipe 23 of the vortex tank to the dissolved air water pipeline in the contact area of the air intake floating tank, and add For a chemical dosing system, such as a PAC dosing system, a chemical dosing system, such as a PAM dosing system, is added to the water inlet pipe 22 of the vortex tank, and it can be put into use after connecting the compressed air pipeline. The specific implementation is as follows:

[0056] Raw water flow 5m 3 / h, raw water emulsified oil 200mg / L, SS60mg / L.

[0057] The design process is: water inlet → pipe flow dissolving tank 27 → primary vortex dis...

Embodiment 3

[0062] The gas dissolving device combining pipe flow and eddy current of the present invention can be used as an ozone oxidation mixing equipment to treat phenol-containing wastewater, and the pipeline of the water to be treated is connected to the water inlet pipe 11 of the pipe flow tank through flanges or other methods, and then it can be put into use . The specific implementation is as follows:

[0063] Wastewater is taken from a gold mine with a flow rate of 3.3m 3 / h, where CN - It is 25mg / L, and the pH is 6.9.

[0064] The design process is: water inlet→pipe flow dissolving tank 27→eddy current dissolving tank 28→water outlet.

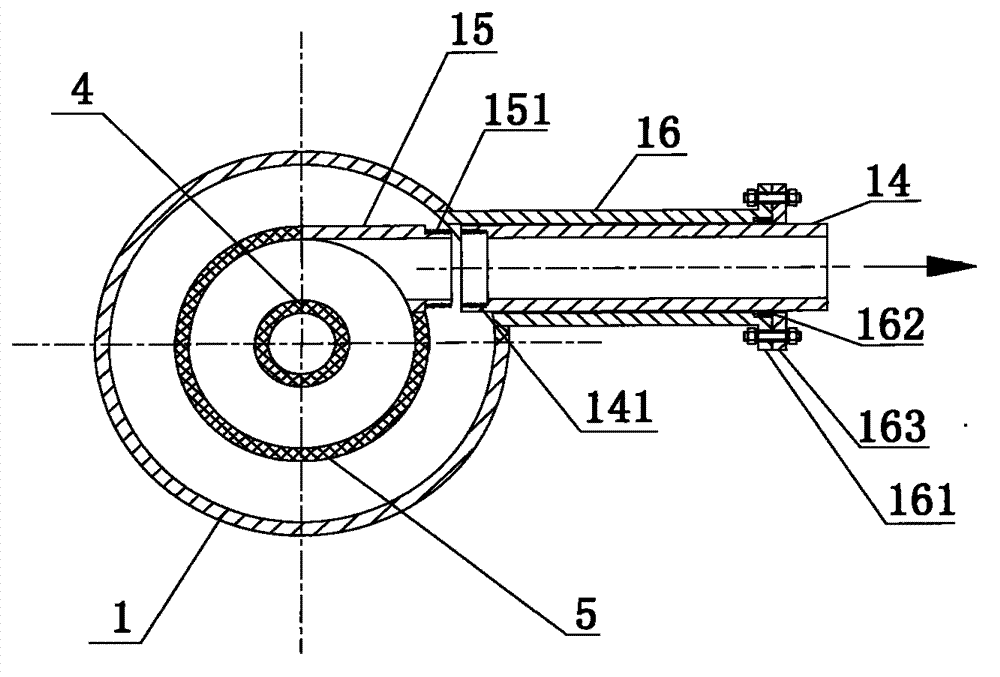

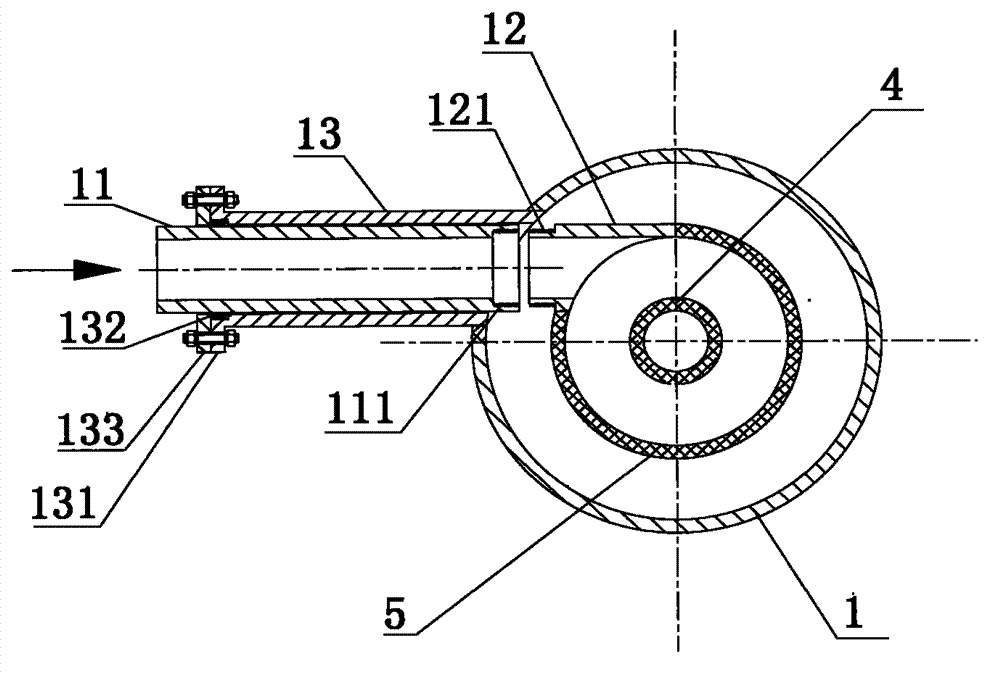

[0065] The ozone generator produces ozone with a concentration of 20mg / L; the ozone enters the annular air channel A in the tube-flow dissolving tank 27, and dissolves ozone into the waste water through the outer ring sintered metal microporous tube 5, and enters the axial air channel B , and dissolve ozone in the waste water through the inn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com