Rotational flow air flotation oil removal device

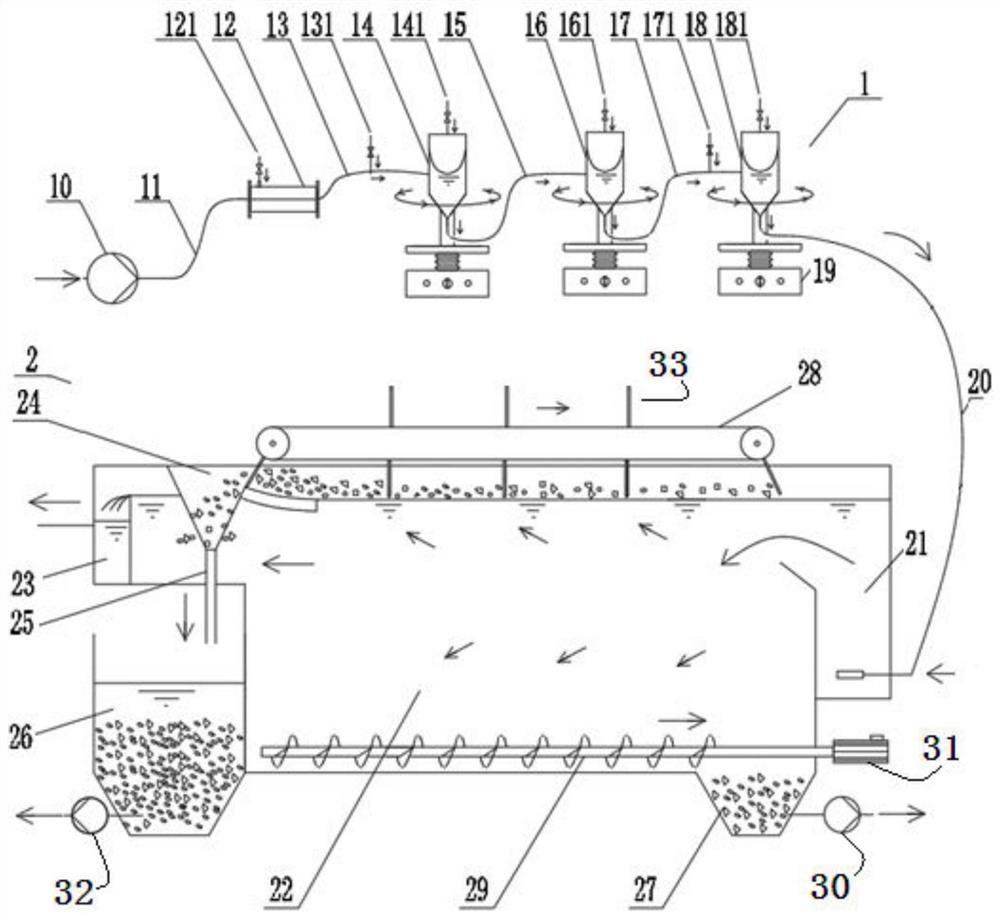

A swirl air flotation and air flotation technology, which is used in grease/oily substance/float removal devices, flotation water/sewage treatment, water/sludge/sewage treatment, etc. Frequent updates and high dissolved gas efficiency, to achieve the effect of high dissolved gas efficiency, small length and large dissolved gas volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1: A slaughterhouse removes the emulsified oil in the water behind the grease trap of its sewage station, and removes suspended solids and part of the particle-type COD and particle-type BOD5 at the same time, and the oil content in the effluent is ≤20mg / L.

Embodiment 2

[0050] Example 2: In an oil field, the emulsified oil in the water behind the grease trap of the sewage station is removed, and the suspended solids and some granular COD and granular BOD5 are removed at the same time, and the oil content in the effluent is ≤20mg / L.

Embodiment 3

[0051] Example 3: A coking plant removes the emulsified oil in the water behind the grease trap of its sewage station, and removes suspended solids and part of the granular COD and granular BOD5 at the same time.

[0052] The invention is an oil removal device, through the innovative swirl flocculation principle and the special swirl reactor and air flotation tank structure design, the efficient removal of emulsified oil is realized, and at the same time, the suspended solids and granular COD (Chemical Oxygen Demand, chemical demand Oxygen) and granular BOD (Biochemical Oxygen Demand, biochemical oxygen demand or biochemical oxygen demand) also have a certain removal effect. The main purpose is the efficient removal of emulsified oil. At the same time, it also has a certain removal effect on suspended solids, particulate COD and particulate BOD, ensuring the normal operation of subsequent biochemicals and reducing the organic load of subsequent biochemicals. The main functions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com