Conductive adhesive composition, electronic device, positive electrode laminate, and method for manufacturing electronic device

A conductive adhesive and electronic device technology, applied in the direction of conductive adhesives, semiconductor/solid device manufacturing, conductors, etc., can solve the problems of reduced carrier injection efficiency, low interface adhesion, and low conductivity of the bonding layer , to achieve excellent adhesion, low surface resistance and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0137] (4) Preparation method of electronic device

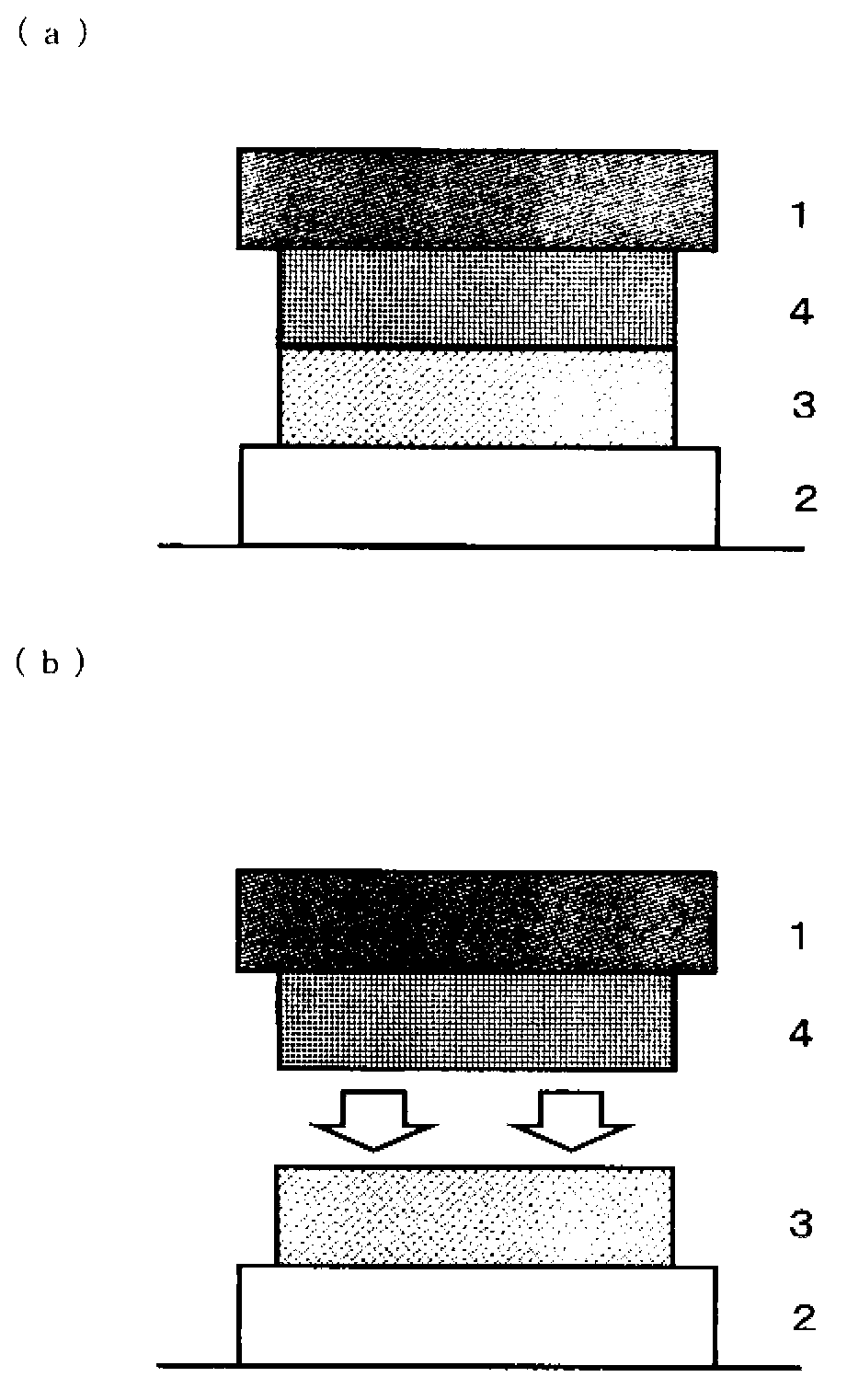

[0138] The manufacturing method of the electronic device of the present invention is characterized in that the step of forming a conductive layer formed of the conductive adhesive composition on the anode layer to form an anode laminate; forming the step of forming the anode layer on the cathode layer A step of forming a photoelectric conversion layer or a light-emitting layer to form a cathode laminate; above the temperature at which the conductive adhesive composition softens, the surface of the photoelectric conversion layer or light-emitting layer of the cathode laminate is bonded to the anode layer The conductive layer surface of the pressing body is bonded.

[0139] Below, through figure 1 (b) The method of manufacturing the electronic device of the present invention will be described in order.

[0140] The integration of the anode layer 1 and the conductive layer 4 is referred to as an anode laminate (described late...

Embodiment 1

[0158] [Preparation of conductive adhesive composition]

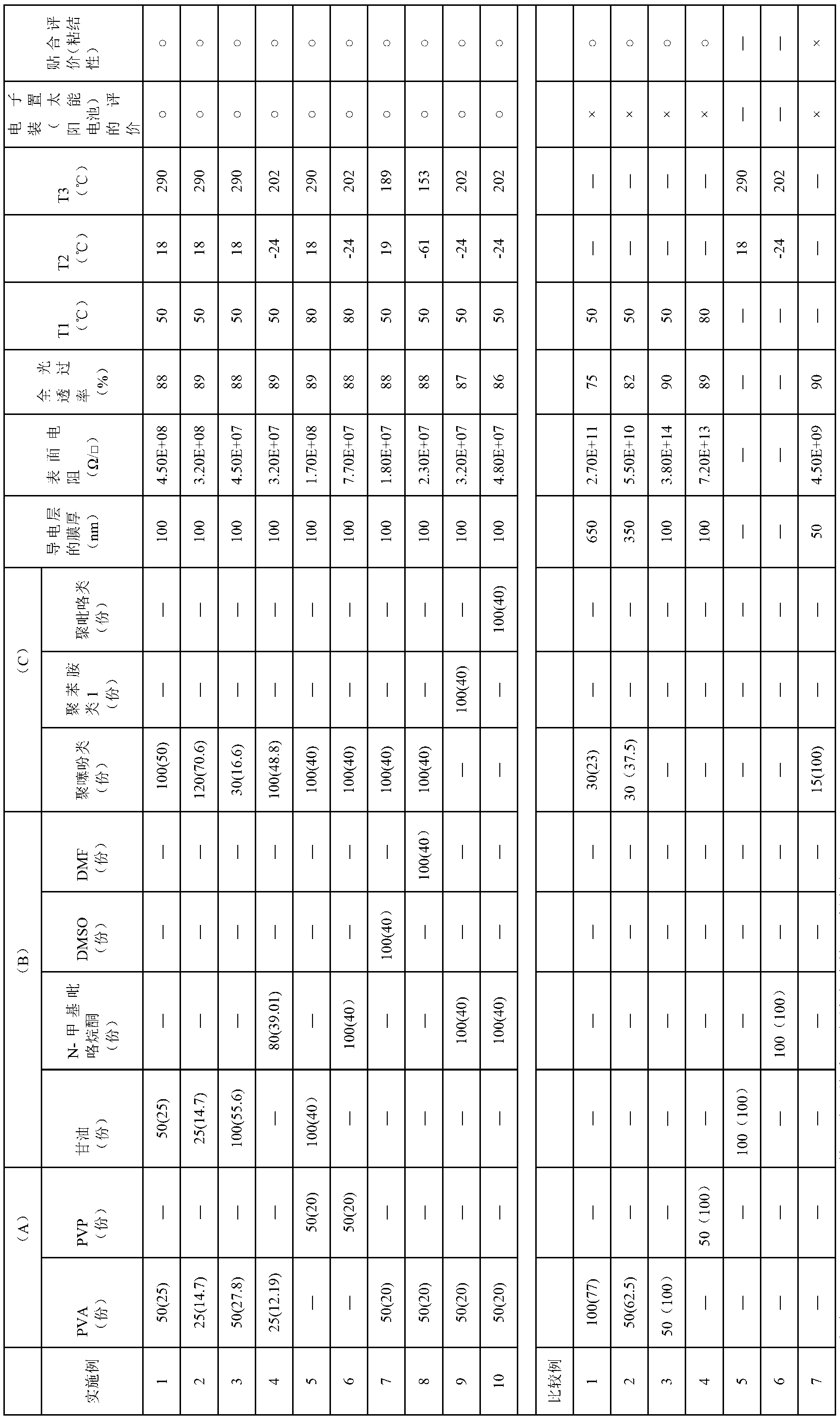

[0159] As the water-soluble polyvinyl polymer of component (A), 50 parts by mass of polyvinyl alcohol [manufactured by Sigma Aldrich Co., Ltd., product name "polyvinyl alcohol", molecular weight Mw = 9100, Tg (T1): 50°C, It is recorded as PVA in Table 1]. As the organic additive of the component (B), 50 parts by mass of glycerin [manufactured by Sigmardrich Co., Ltd., product name "glycerin", melting point (T2): 18° C., boiling point (T3): 290° C.] was used. As the conductive polymer polythiophenes of the component (C), 10,000 parts by mass of a mixture of poly(3,4-ethylene oxidethiophene) (PEDOT) and polystyrene sulfonic acid (PSS) (PEDOT:PSS ) [manufactured by H.C. Starck, product name "Clevious PVP.AI4083, active ingredient 1% by mass", described as polythiophenes in Table 1].

[0160] The components (A), (B) and (C) were dissolved in 200 parts by mass of pure water to prepare a coating solution of a conductive adh...

Embodiment 2、3

[0170] Except having changed to the blending of the following Table 1, it carried out similarly to Example 1, and obtained the electronic device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com