Power circuit for light emitting diode (LED) illuminating lamp

A technology of LED lighting and power circuits, which is applied in the layout of electric lamp circuits, electric light sources, lighting devices, etc. It can solve problems such as accelerated light decay, shortened LED service life, and hot lamp beads, so as to reduce heat generation and prevent fatigue Phenomenon, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

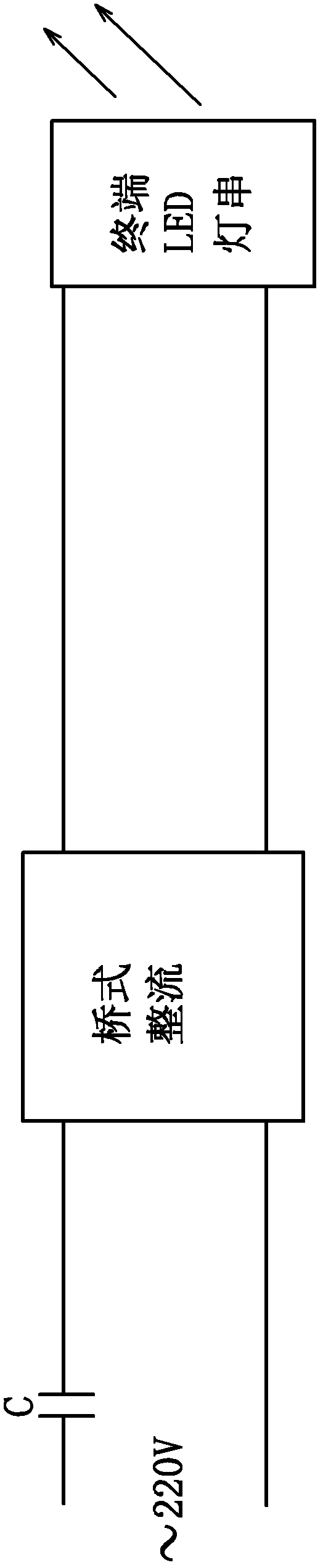

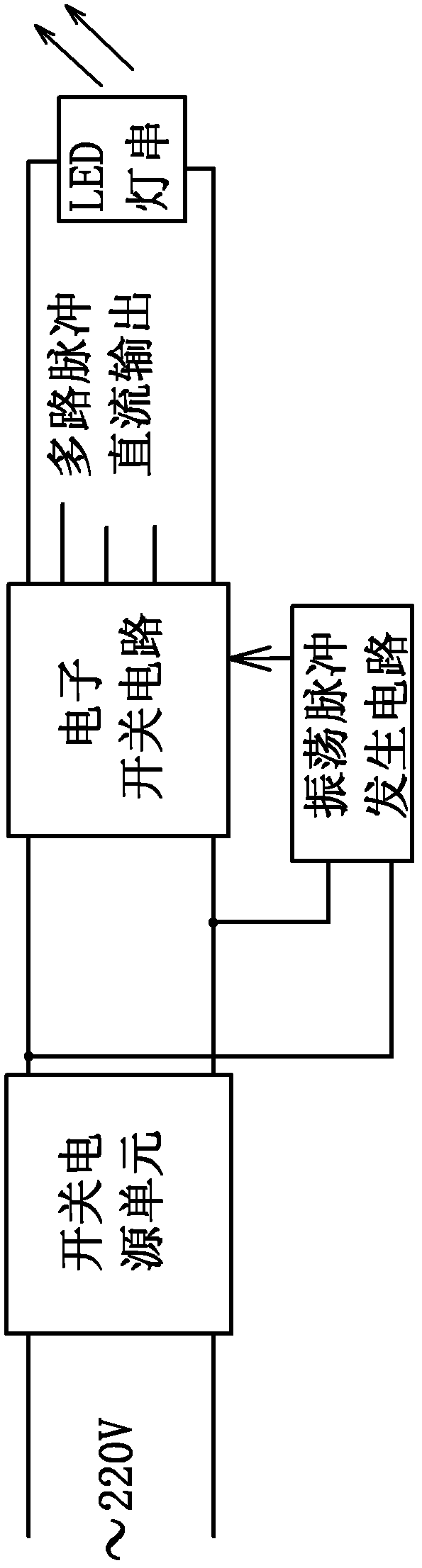

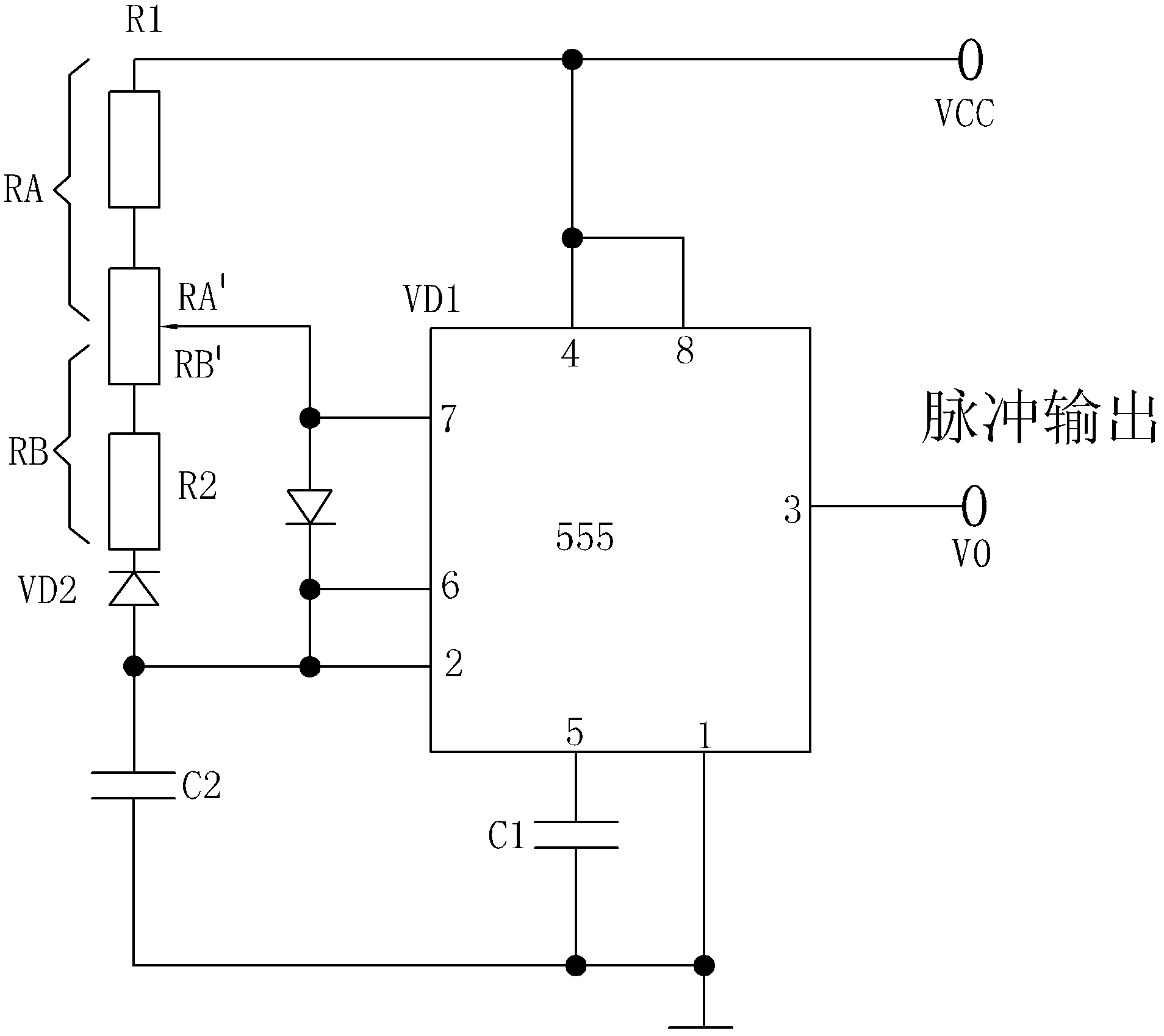

[0011] The LED lighting power supply circuit of the utility model is a conversion circuit for converting mains electricity into DC pulsating voltage. The pulsating frequency is between 100 and 200 Hz. If the pulsating frequency is too low, flickering will occur. If the pulsating frequency is too high, the cooling effect will be reduced. Not noticeable, 100 to 120 Hz is the best. The circuit can have various forms. For low-power LED lighting (not exceeding 15W), a full-bridge rectifier DC pulsating power supply circuit with a current-limiting capacitor connected in series on the AC side can be used, such as figure 1 As shown, the difference from the traditional full-bridge rectifier circuit is that there is no filter capacitor on the DC output side, and the direct output of the DC pulsating voltage is the power supply of the low-power LED lighting. The capacity of the current-limiting capacitor is determined according to the specific power of the LED lighting. I won't repeat th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com