Semiconductor device and manufacturing method thereof

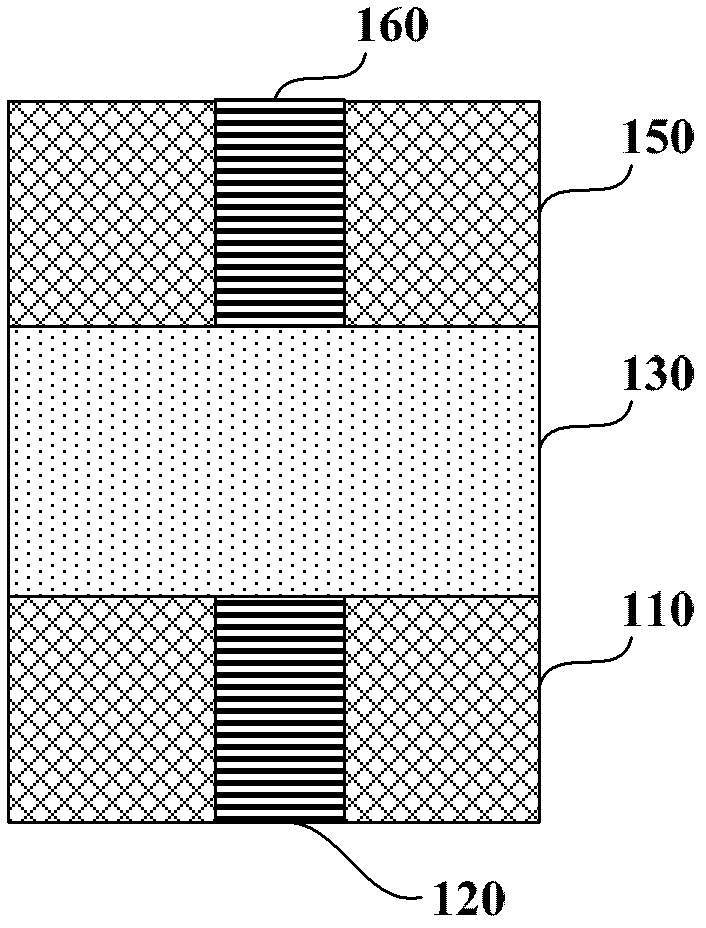

A technology for semiconductors and devices, applied in the field of semiconductor devices and their manufacturing, can solve the problems of small lower electrode contact area and difficult to meet the driving current, and achieve the effect of reducing the contact area and avoiding the limitation of lithography capability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0075] The formation process of the phase change unit and the sidewall electrodes can be the same as the preparation method in the previous embodiment. The method can include:

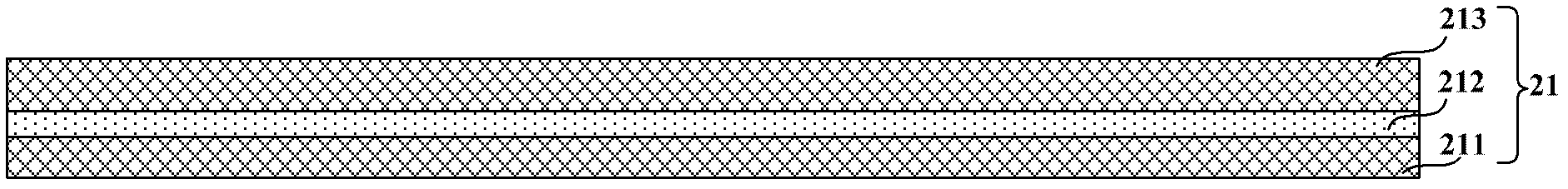

[0076] First, the lower insulating material layer 211, the phase change material layer 212 and the upper insulating material layer 213 are sequentially deposited on the first insulating material layer 251, as Figure 4D shown.

[0077] The material of the two insulating material layers may be insulating oxide. Wherein, the materials of the lower insulating material layer 211 and the upper insulating material layer 213 may be the same or different. The material of the phase-change material layer 212 may be GeSbTe chalcogenide, such as GeSbTe, N-Ge-Sb-Te, As-Sb-Te or In-Sb-Te.

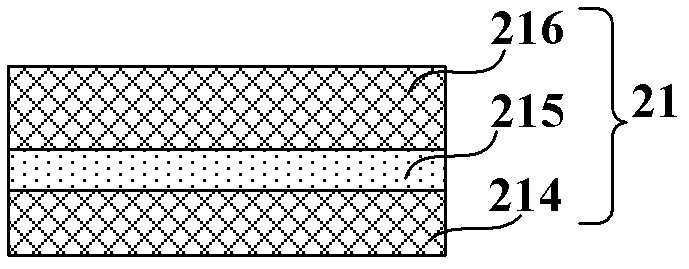

[0078] Then, part of the materials of the above three layers are removed by etching to form the phase change unit 21 . The formed phase change unit 21 includes a lower insulating material layer 214 , an upper insulating mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com