Rated voltage 12/20kv~26/35kv mine photoelectric composite medium voltage towing cable and its preparation process

A photoelectric composite and rated voltage technology, applied in the direction of power cables, cable/conductor manufacturing, power cables including optical transmission components, etc., can solve problems such as service life reduction, bending fatigue, etc., to prolong service life and improve flame retardancy , Improve the effect of UV resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

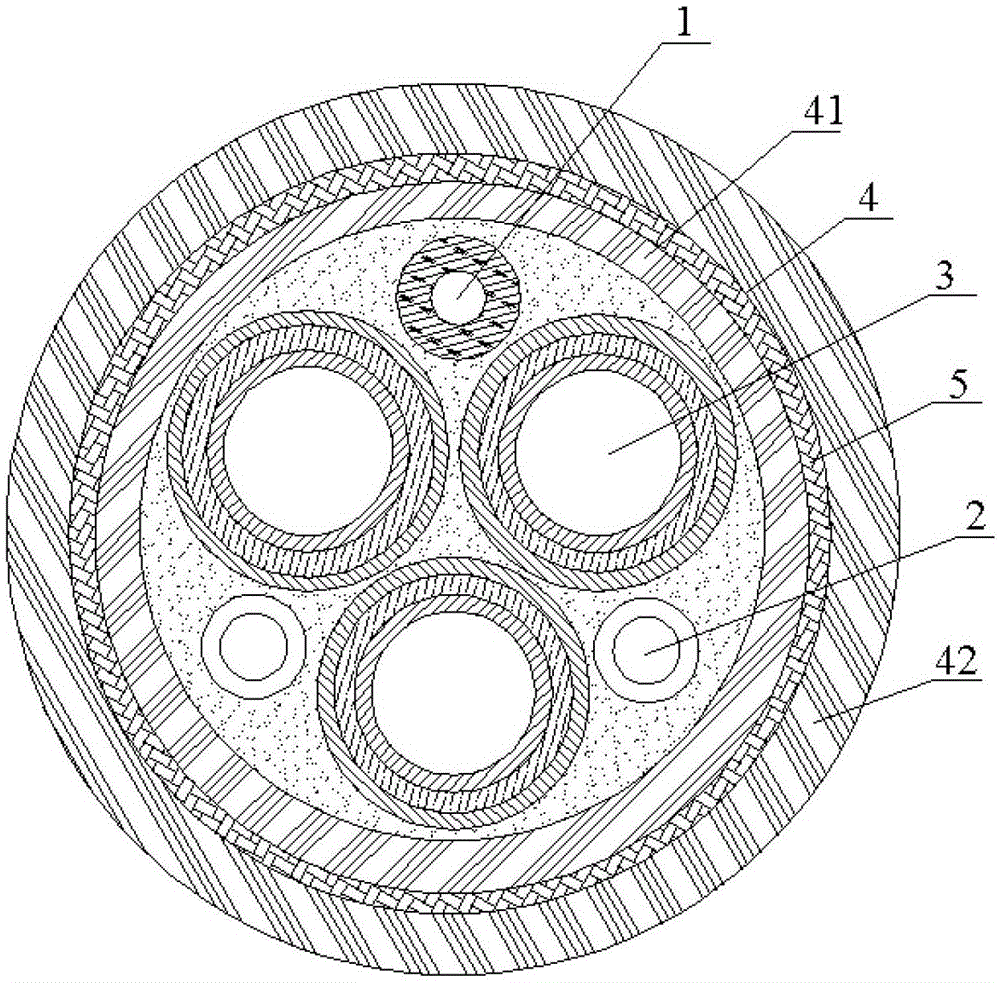

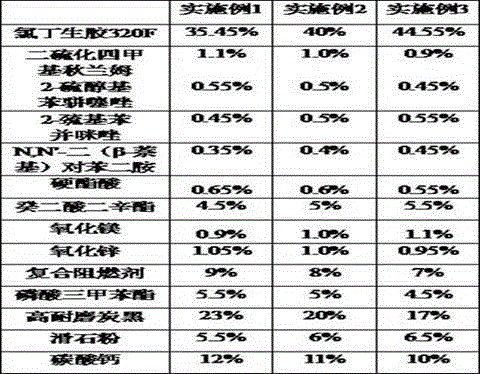

[0034] Embodiment 1: A rated voltage of 12 / 20kV~26 / 35kV mining photoelectric composite medium-voltage towing cable, the voltage towing cable includes a photoelectric unit 1, a ground core 2 and at least three power core conductors 3, a protective The sheath layer 4 covers the outer surface of the photoelectric unit 1, the ground core 2 and at least three power core conductors 3; the sheath layer 4 includes an inner sheath layer 41 and an outer sheath layer 42, the inner sheath layer A braided reinforcing layer 5 is provided between the sheath layer 41 and the outer sheath layer 42, and the inner sheath layer 41 and the outer sheath layer 42 are composed of the following components by weight percentage as shown in Table 1:

[0035] Table 1

[0036]

[0037] The preparation technology of above-mentioned inner sheath layer and outer sheath layer, comprises the following steps:

[0038] Step 1. Mixing the chloroprene rubber 320F35~45% in an internal mixer at 100°C~120°C for 5m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com