Double-shielded instrument cable for flame-resistant and fire-resistant ship and manufacture method thereof

A flame-retardant and fire-resistant, instrument cable technology, used in cable/conductor manufacturing, insulating cables, insulating conductors/cables, etc. Facilitates stretch transfer, enhances impregnation against moisture, and eliminates voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

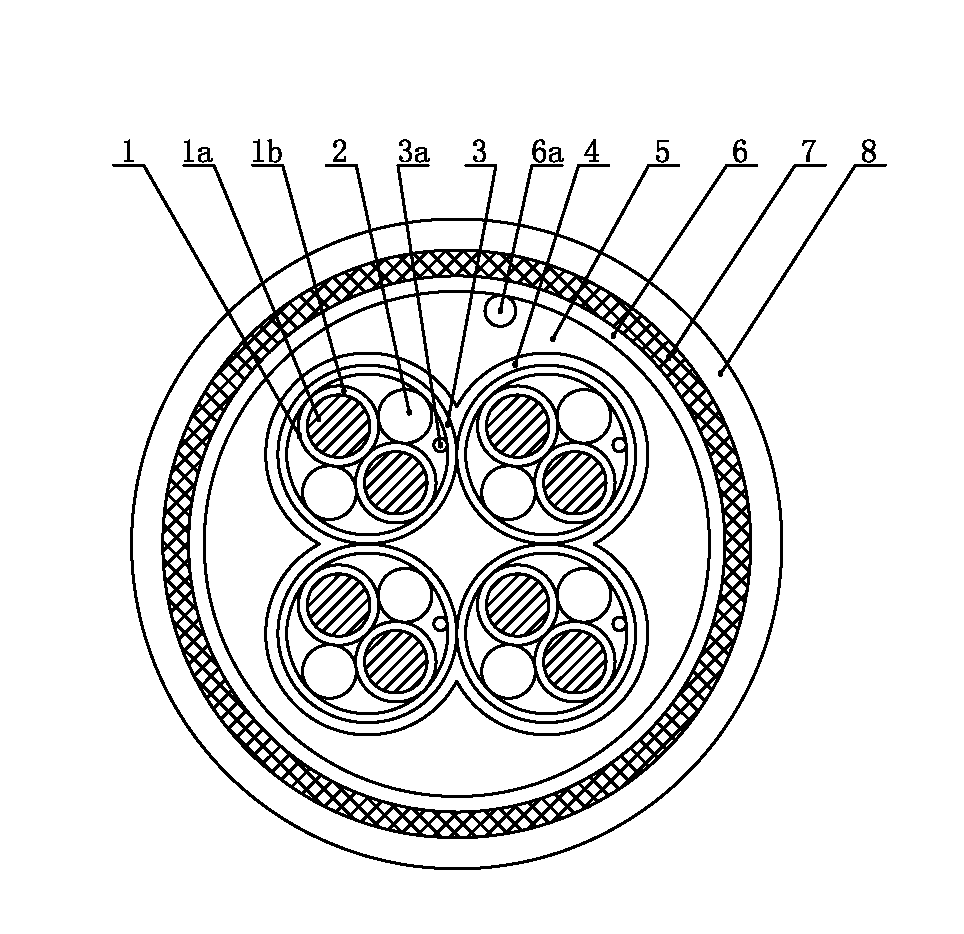

[0023] Such as figure 1 As shown, the flame-retardant and fire-resistant marine double-shielded instrument cable of the present invention includes the following steps in turn: the outer periphery of the stranded copper conductor 1a is extruded with a flame-retardant and fire-resistant ethylene-propylene rubber insulating layer 1b to form an insulating core 1, and the insulating core 1 is twisted in pairs The twisted wire pairs are combined to form a pair of twisted wires, and the gaps of the twisted wire pairs are filled with flame-retardant non-hygroscopic fiber filler 2, and each pair of twisted wire pairs adopts different twisting pitches; the outer circumference of each pair of twisted wire pairs is wound The twisted pair copper foil shielding layer 3 constitutes a twisted group; the copper foil of the twisted pair copper foil shielding layer 3 faces inward and the inner side is provided with a twisted pair copper drain wire 3a, and a twisted pair copper drain wire 3a It r...

Embodiment 2

[0028] Such as figure 1 As shown, the flame-retardant and fire-resistant marine double-shielded instrument cable of the present invention includes the following steps in turn: the outer periphery of the stranded copper conductor 1a is extruded with a flame-retardant and fire-resistant ethylene-propylene rubber insulating layer 1b to form an insulating core 1, and the insulating core 1 is twisted in pairs The twisted wire pairs are combined to form a pair of twisted wires, and the gaps of the twisted wire pairs are filled with flame-retardant non-hygroscopic fiber filler 2, and each pair of twisted wire pairs adopts different twisting pitches; the outer circumference of each pair of twisted wire pairs is wound The twisted pair copper foil shielding layer 3 constitutes a twisted group; the copper foil of the twisted pair copper foil shielding layer 3 faces inward and the inner side is provided with a twisted pair copper drain wire 3a, and a twisted pair copper drain wire 3a It r...

Embodiment 3

[0033] Such as figure 1 As shown, the flame-retardant and fire-resistant marine double-shielded instrument cable of the present invention includes the following steps in turn: the outer periphery of the stranded copper conductor 1a is extruded with a flame-retardant and fire-resistant ethylene-propylene rubber insulating layer 1b to form an insulating core 1, and the insulating core 1 is twisted in pairs The twisted wire pairs are combined to form a pair of twisted wires, and the gaps of the twisted wire pairs are filled with flame-retardant non-hygroscopic fiber filler 2, and each pair of twisted wire pairs adopts different twisting pitches; the outer circumference of each pair of twisted wire pairs is wound The twisted pair copper foil shielding layer 3 constitutes a twisted group; the copper foil of the twisted pair copper foil shielding layer 3 faces inward and the inner side is provided with a twisted pair copper drain wire 3a, and a twisted pair copper drain wire 3a It r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com