Prism sheet and backlight unit including same

A prism sheet, prism technology, applied in prisms, optical components, optics, etc., can solve problems such as reducing product appearance and brightness, product defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

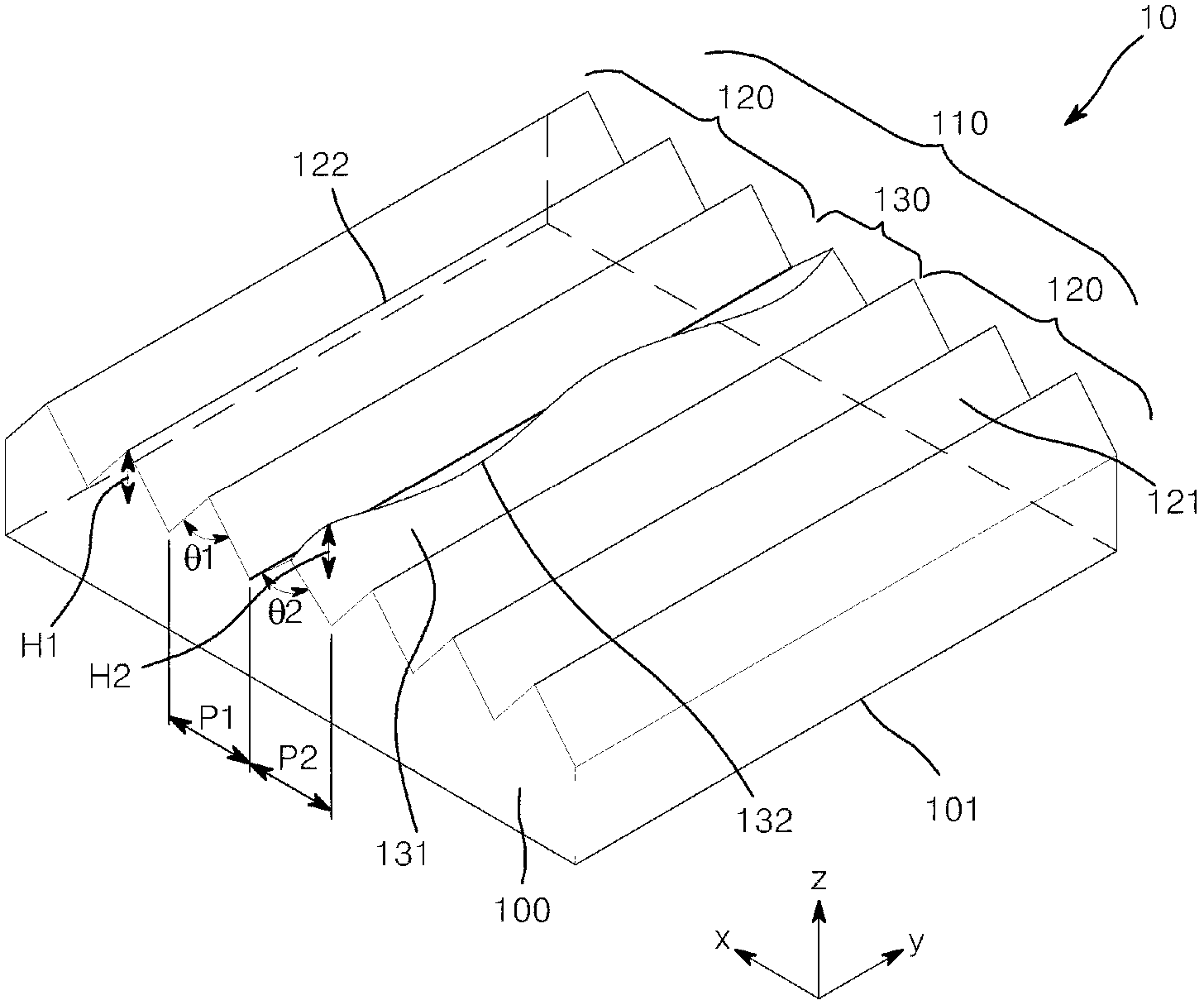

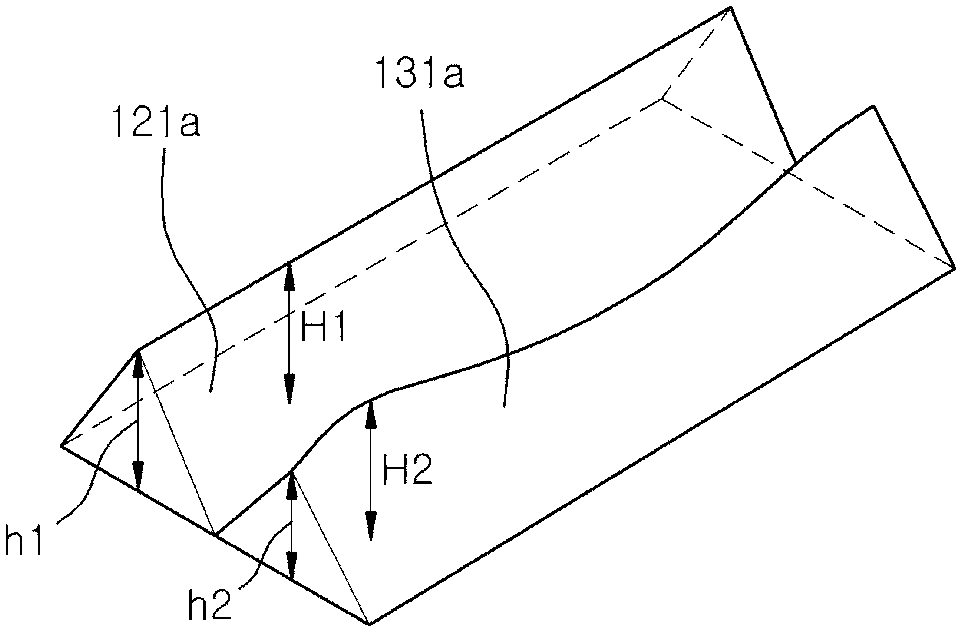

[0077] A prism sheet including a base film and optical refraction segments formed on the base film is fabricated. The optical refraction section includes a first prism part (A1) with 19 prisms and a second prism part (A2) with a single prism, the first prism part (A1) and the second prism part (A2) according to A1A1... The sequence of A2...A1A1 is arranged. The prisms of the first prism section had a triangular cross-section, a height of 25 μm, and a pitch of 50 μm. The prisms of the second prism section had a triangular cross-section, a height of 23-27 μm, a maximum height of 27 μm, and a pitch of 50 μm. A line connecting the heights of the prisms of the second prism portion has a waveform.

example 2

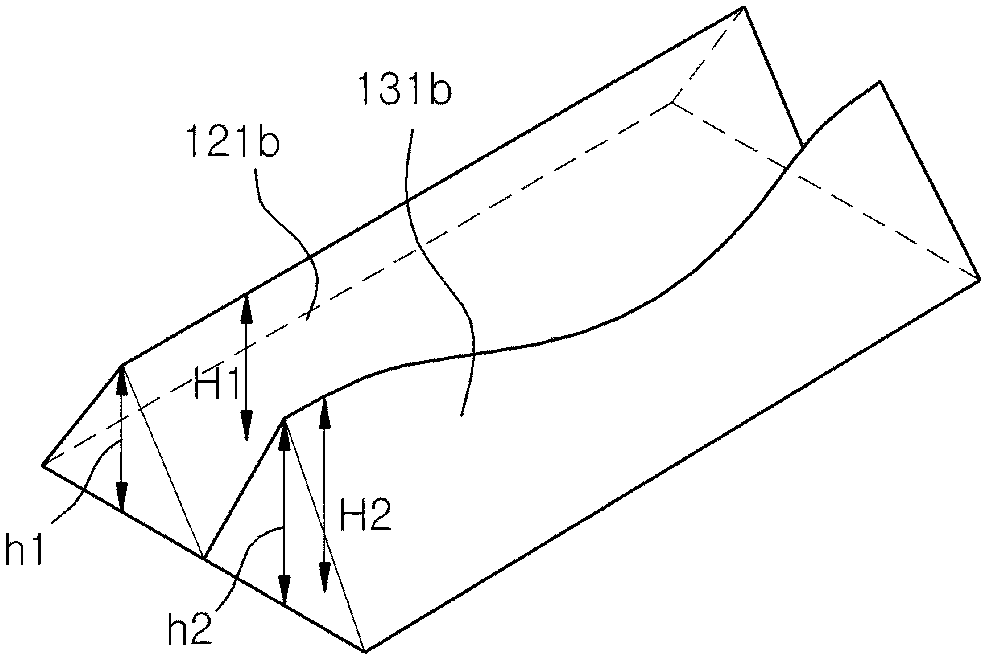

[0079] A prism sheet including a base film and optical refraction segments formed on the base film is fabricated. The optical refraction section includes a first prism part (A1) with 10 prisms and a second prism part (A2) with a single prism, the first prism part (A1) and the second prism part (A2) according to A1A1... The sequence of A2...A1A1 is arranged. The prisms of the first prism section had a triangular cross-section, a height of 25 μm, and a pitch of 50 μm. The prisms of the second prism section had a triangular cross-section, a height of 31-35 μm, a maximum height of 35 μm, and a pitch of 66 μm. A height difference between the prisms of the first prism part and the prisms of the second prism part is 6-10 μm. A line connecting the heights of the prisms of the second prism portion has a waveform.

example 3

[0081] A prism sheet including a base film and optical refraction segments formed on the base film is fabricated. The optical refraction section includes a first prism part (A1) with 19 prisms and a second prism part (A2) with a single prism, the first prism part (A1) and the second prism part (A2) according to A1A1... The sequence of A2...A1A1 is arranged. The prisms of the first prism section had a triangular cross-section, a height of 25 μm, and a pitch of 50 μm. The prisms of the second prism section had a triangular cross-section, a height of 31-35 μm, a maximum height of 35 μm, and a pitch of 66 μm. The second prism has a radius of curvature of 2 μm. A height difference between the prisms of the first prism part and the prisms of the second prism part is 6-10 μm. A line connecting the heights of the prisms of the second prism portion has a waveform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com