Method for preparing ecological organic fertilizer from organic waste

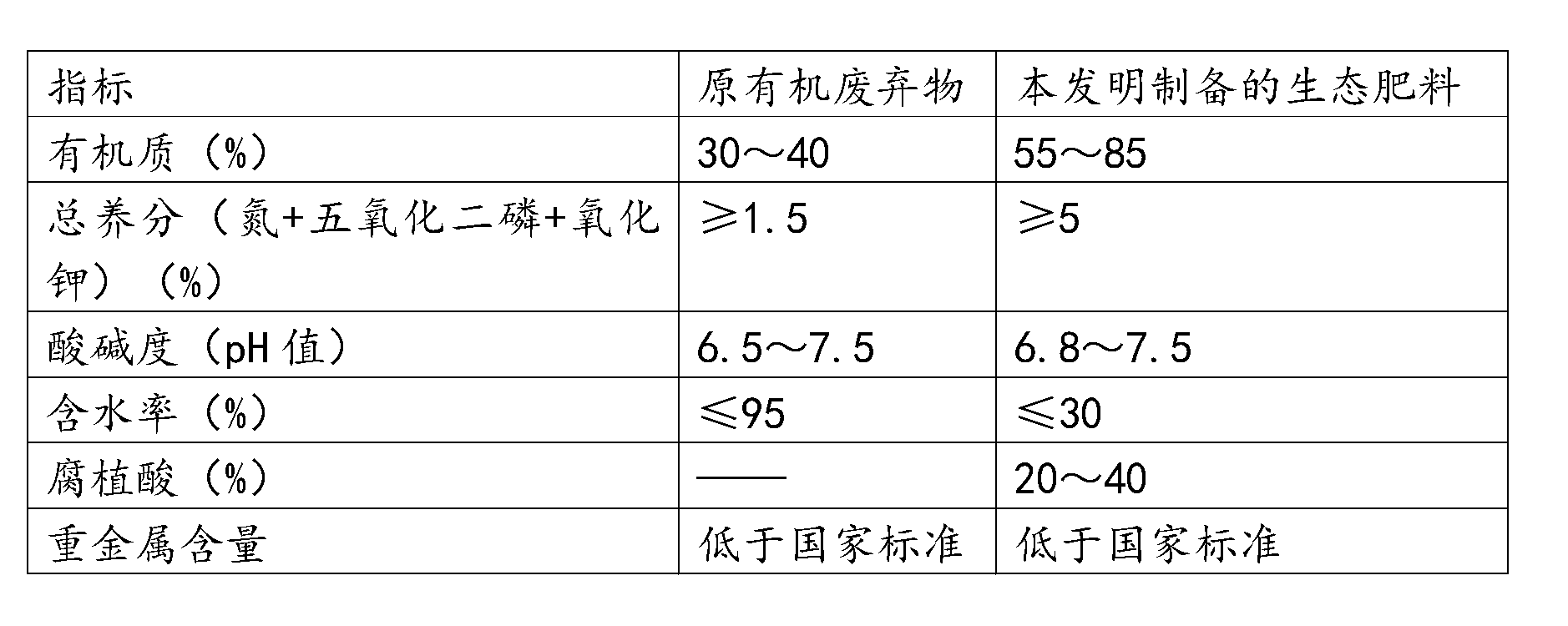

A technology of organic waste and organic fertilizer, which is applied in the environmental field, can solve the problems of complex process design and equipment, unpassivated heavy metals, and increased dehydration costs, so as to avoid difficult control of odor, accelerate the reproduction speed, and shorten the fermentation cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

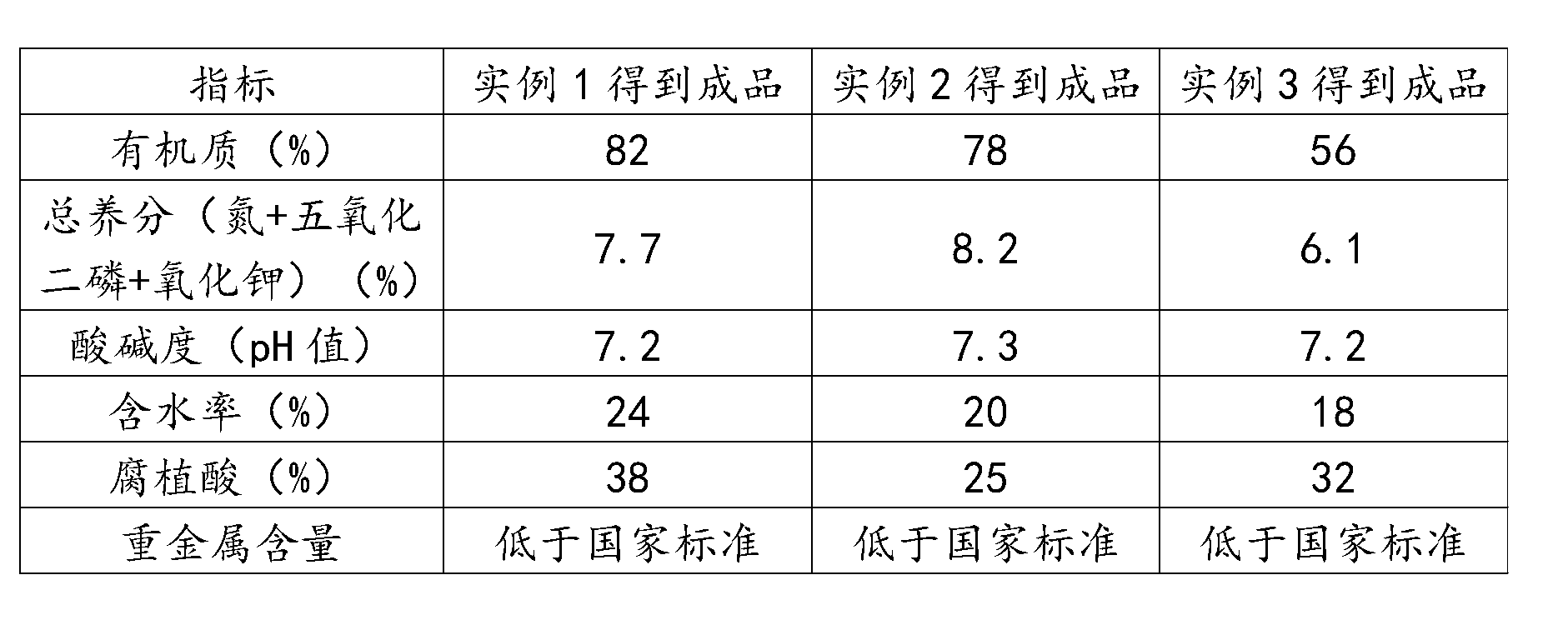

Embodiment 1

[0038] Put 1 ton of municipal sludge (85% water content by weight) and 500kg of medicinal residue (10% water by weight) into the subcritical water reactor, then add NaOH to adjust the pH to 8, and pass steam into the reactor , adjust the temperature to 200°C, the pressure to 1.5MPa, turn on the mixer and stir to make it evenly heated, and react for 30min. After the reaction is completed, the sludge is further dried to a water content of 55% by weight.

[0039] Add 10.5 kg of bacillus, 2.5 kg of filamentous fungus, and 2.0 kg of mold, and mix evenly to make a heap. After 3 days, the temperature of the heap will rise to 60°C and keep at 55-70°C for 7 days; when the temperature exceeds 65°C, Turn the stack until the temperature does not change any more to obtain the finished product.

Embodiment 2

[0041] Put 1 ton of distiller's grains (water content 62% by weight), rice bran 600kg (water content 8% by weight) into the subcritical water reactor, then add NaOH to adjust the pH to 7.5, pass steam into the reactor to adjust the temperature To 230°C, pressure to 2.7MPa, turn on the mixer to stir to make it evenly heated, and react for 45min. After the reaction is completed, the organic waste is further dried to a water content of 50% by weight.

[0042] Add 12.6 kg of bacillus, 2.7 kg of filamentous fungi, and 2.7 kg of yeast, and mix evenly to make a heap. After 2 days, the temperature of the heap will rise to 70°C, and keep it at 55-70°C for 5 days. When the temperature exceeds 65°C , turn the stack until the temperature no longer changes, and get the finished product.

Embodiment 3

[0044] Put 1 ton of animal manure into the subcritical water reactor (water content percentage is 22%), straw 200kg (water content percentage percentage is 8%), then add NaOH to adjust the pH to 8.5, pass steam into the reactor to adjust When the temperature reaches 260°C and the pressure reaches 4.9 MPa, turn on the mixer and stir to make it evenly heated, and react for 40 minutes. After the reaction, the sludge was further dried to a moisture content of 55%.

[0045] Add 10.5 kg of bacillus, 2.5 kg of filamentous fungus and 2.5 kg of mold, and mix evenly to make a heap. After 3 days, the temperature of the heap will rise to 70°C and keep at 55-70°C for 6 days. When the temperature exceeds 65°C, Turn the stack until the temperature does not change any more to obtain the finished product.

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com