Methanol recombination device started by waste heat of engine

A technology of engine waste heat and recombination, applied in the direction of inorganic chemistry, chemical instruments and methods, non-metallic elements, etc., can solve problems such as complex equipment, reduction of exhaust gas emissions, and reduction of NOx emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

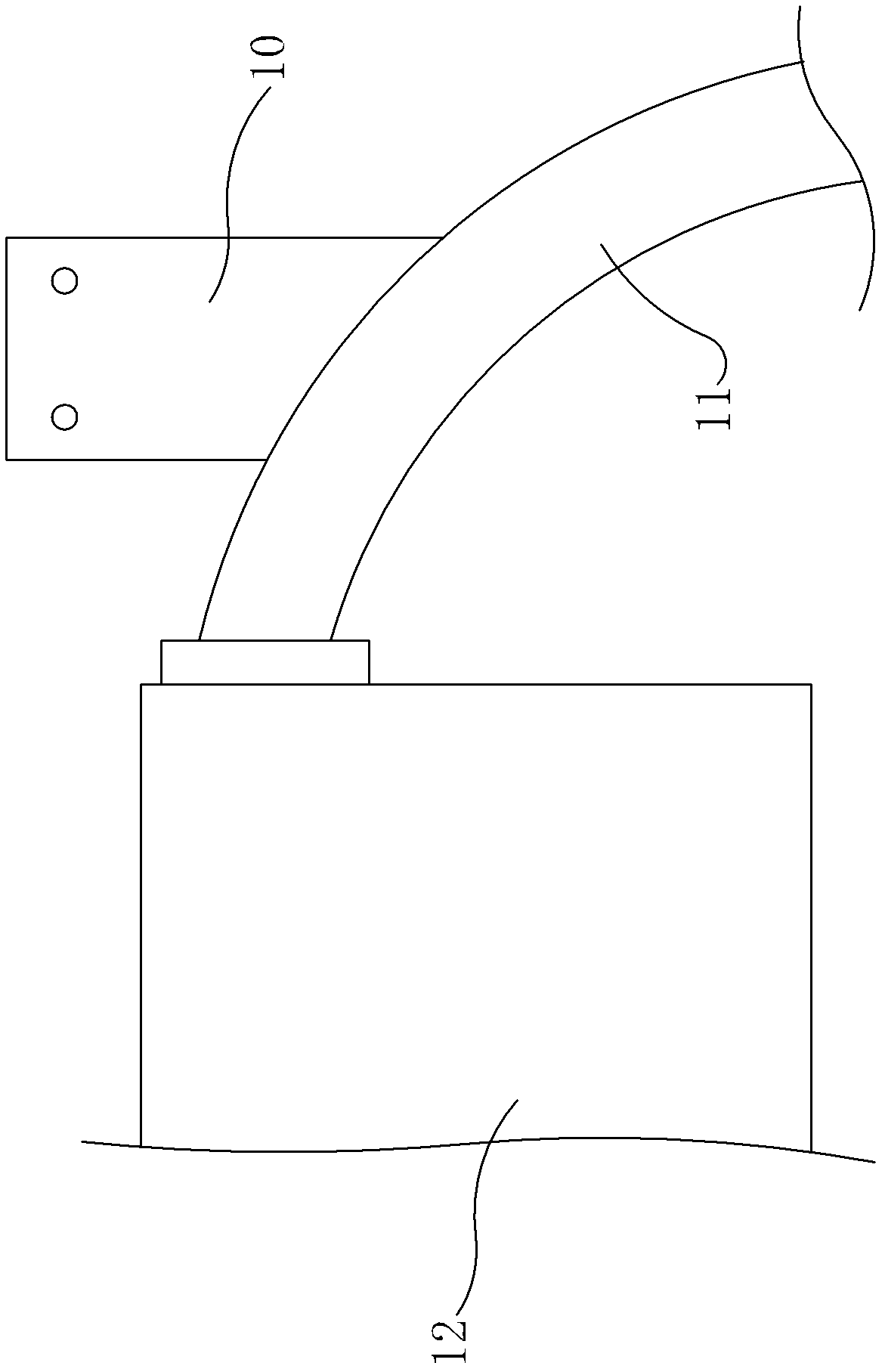

[0037] In order to break through the shortcomings and limitations of the above three methods, without changing the structure of the original internal combustion engine, the present invention uses engine waste heat as a hydrogen production energy source with novel equipment to produce hydrogen, which is injected into the engine to achieve a 20-30% benefit of hydrogen combustion. figure 1 The methanol reformer 10 is shown positioned against the exhaust pipe 11 to absorb heat from the exhaust gas emitted by the engine 12 . However, the exhaust pipe 11 made of pig iron has many small pores and poor conductivity. It takes 20 to 30 minutes to conduct heat to the methanol reformer 10 until the methanol reformer 10 absorbs enough heat to start the operation. slow.

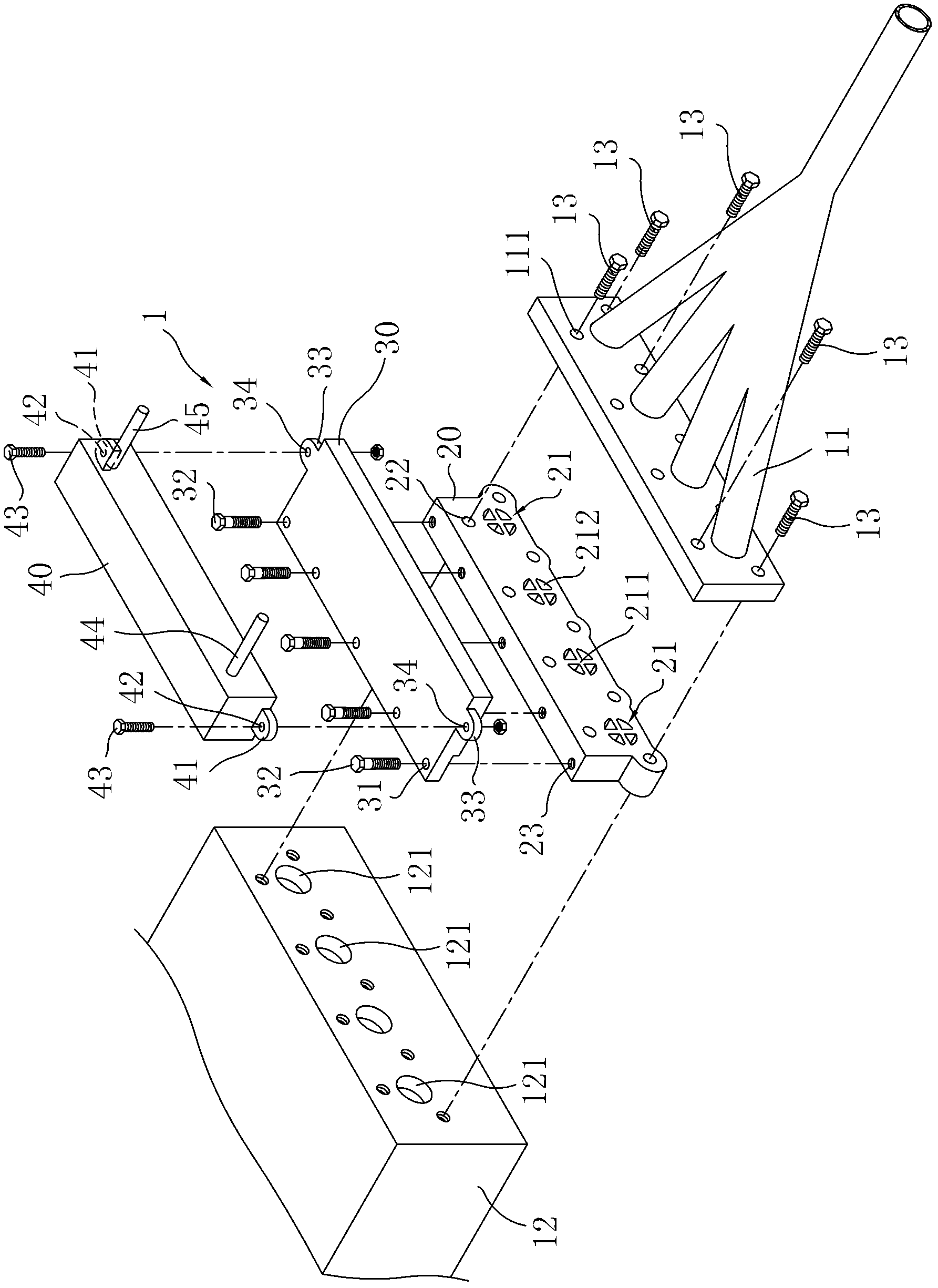

[0038] see figure 2 and image 3. The methanol recombiner 1 disclosed by the present invention is started by waste heat of the engine, mainly uses the waste heat generated by the ignition and explosion of the fuel in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com