A ship position tracking system that can be used for long-distance transportation of shipping equipment

A tracking system and long-distance technology, applied in the field of machinery, can solve the problems of dust pollution, material loss, the inability of the discharge port and the cabin to be in close contact, and achieve the effect of accurate tracking and testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

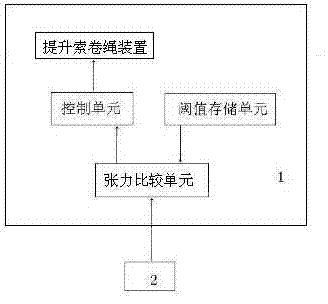

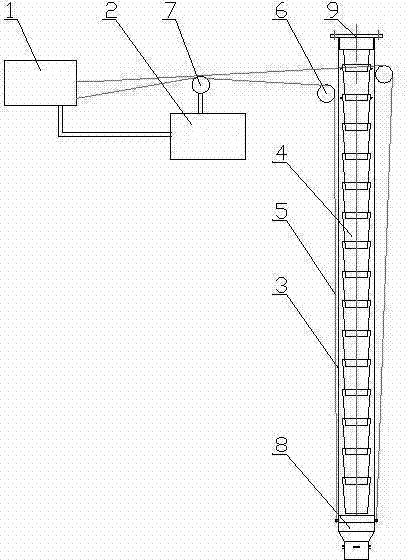

[0029] Ship position tracking system of the present invention, from figure 1 It can be seen in the figure that it includes a drop tube lifting control device 1, a tension sensor 2 and a telescopic drop tube 3; The casing 4 is surrounded by at least two hoisting cables 5 connected to the casing 4. In this embodiment, two hoisting cables 5 are arranged. The discharge port of the conveying and loading equipment is connected, the lower end discharge port 8 of the telescopic drop pipe 3 is sealed and fixedly connected with the cabin, and the lower end of the lifting cable 5 is connected with the discharge port 8; Correspondingly, the same number of hoisting pulleys 6 as the hoisting ropes 5 is provided, that is, each hoisting rope 5 corresponds to a hoisting pulley 6, and the hoisting pulleys are arranged on the top of the telescopic drop pipe 3. In this embodiment, Two lifting pulleys 6 are provided.

[0030] The tension sensor 2 is arranged between the drop tube lifting control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com