Vacuum sealing clip

A technology of vacuum sealing and sealing parts, applied in the direction of pipes/pipe joints/pipes, pipe connection layout, mechanical equipment, etc., can solve the problems of easy gas leakage, easy breakage, glass pipe connection problems can not be well solved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

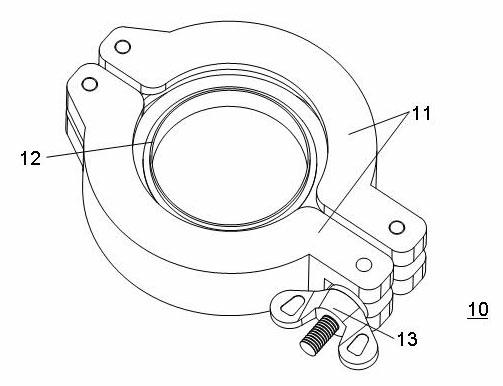

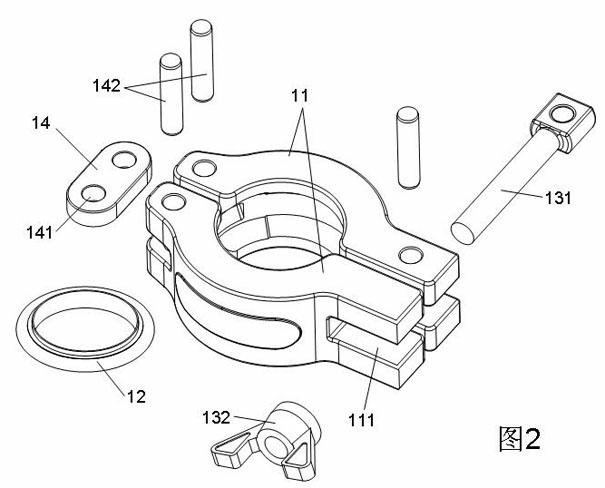

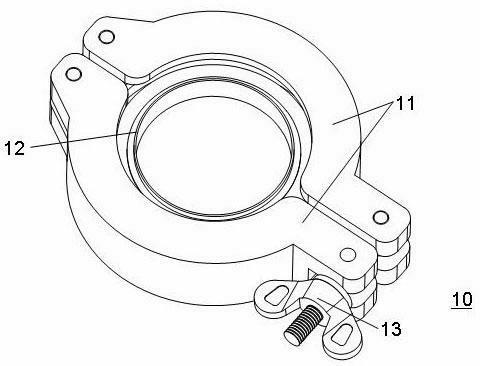

[0018] see figure 1 , figure 2 As shown, the vacuum sealing clip 10 of the present invention includes two semicircular flange snap rings 11, a sealing member 12 and a fastener 13, wherein the two flange snap rings 11 are arranged symmetrically to form a hoop shape, and One ends of the two flange snap rings 11 are pinned together, the seal 12 is arranged on the inner ring of the flange snap rings 11, the fastener 13 is arranged on the other end of the two flange snap rings 11, and the two flange snap rings 11 The other ends are locked together. The specific structure is as follows: a connecting piece 14 is arranged between one end of the two flange snap rings 11, and pin holes 141 are respectively provided at both ends of the connecting piece 14, and a pin shaft is respectively provided at the ends of the two flange snap rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com