injection molding machine

A technology of injection molding machine and supporting part, which is applied in the field of injection molding machine to achieve the effect of reducing magnetic field leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

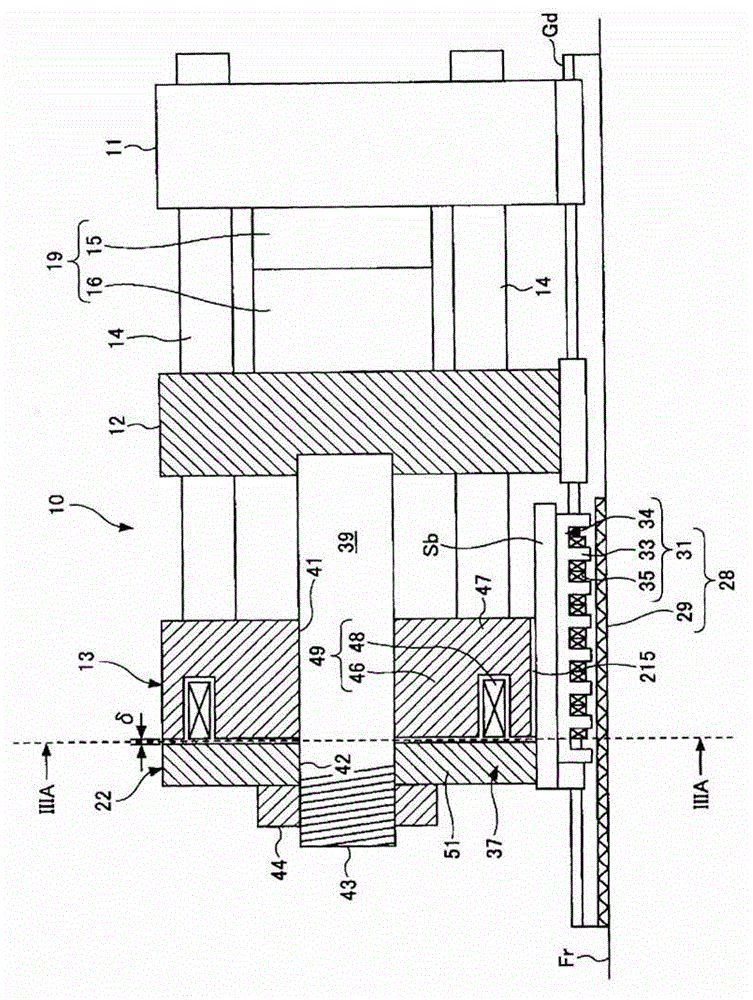

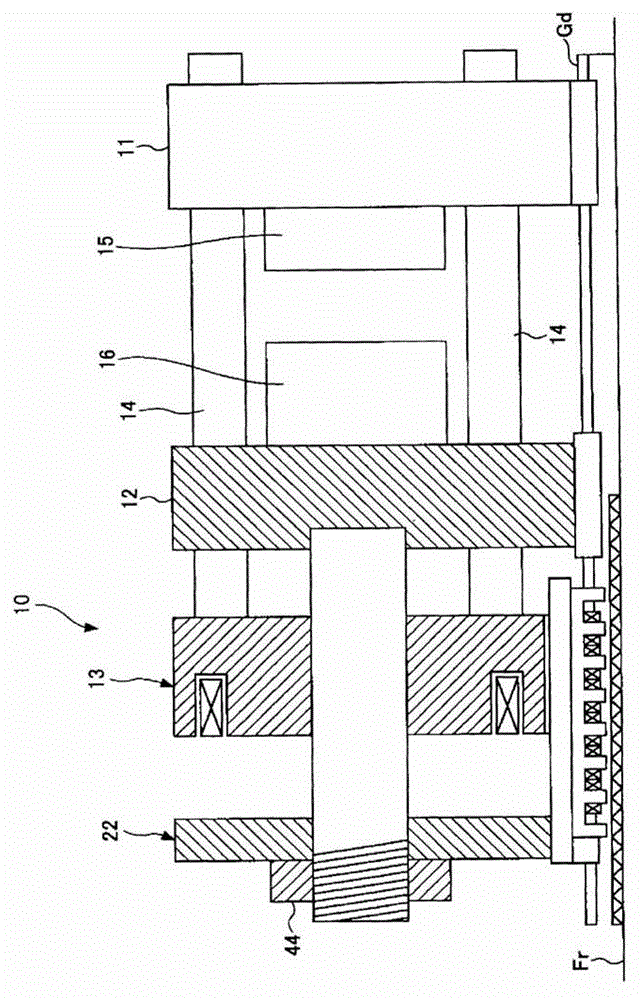

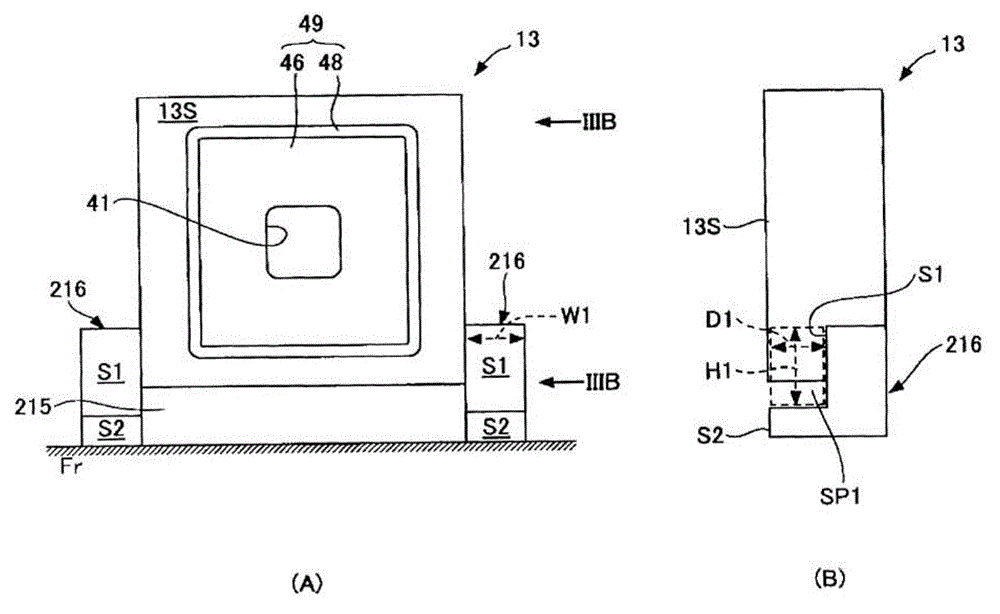

[0017] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In addition, in the present embodiment, the mold clamping device will be described assuming that the moving direction of the movable platen when the mold is closed is set to the front, and the moving direction of the movable platen when the mold is opened is set as the rear.

[0018] figure 1 It is a figure which shows the state at the time of mold closing of the injection molding machine concerning 1st Embodiment of this invention, figure 2 It is a figure which shows the state at the time of mold opening of the injection molding machine concerning 1st Embodiment of this invention. In addition, respectively in figure 1 and figure 2 The slanted hatching portion indicates the section of the vertical plane passing through the centerline of the injection molding machine.

[0019] figure 1 Among them, 10 represents the mold clamping device, Fr represents the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com