VCSEL (vertical cavity surface emitting laser) drive circuit

A vertical cavity surface and drive circuit technology, applied in the direction of lasers, laser components, semiconductor lasers, etc., can solve the problem of large inductance area on the chip, and achieve the effect of reducing the chip area and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

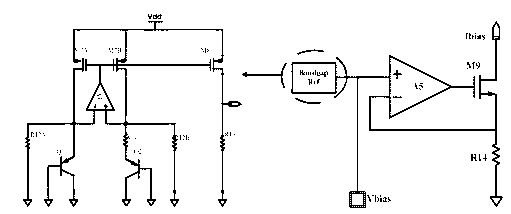

[0014] A common anode vertical cavity surface emitting laser (VCSEL) drive circuit, including an input buffer stage, a three-stage amplifier circuit, a current switch circuit and a bias current source circuit, the function of the input buffer is to realize impedance matching and adjust the operation of the circuit Level, resistors R1 and R2 are used to provide a suitable working level, and resistors R3 and R4 provide input impedance matching; the three-stage amplification structure adopts a cascaded full differential amplification structure with low load impedance to amplify the input signal and provide Sufficient gain, so that within a given range of input signal amplitude, sufficient voltage swing can be obtained on the current switch tube to promote the effective operation of the current switch; in this embodiment, the modulation current is directly coupled to the cathode of the VCSEL, and the bias current source passes through The off-chip inductor is DC-coupled to the cath...

Embodiment 2

[0016] A common cathode vertical cavity surface emitting laser (VCSEL) driving circuit, such as Figure 4 As shown, it includes an input buffer stage, a three-stage amplifier circuit, a current switch circuit and a bias current source circuit. The function of the input buffer is to achieve impedance matching and adjust the working level of the circuit. Resistors R1 and R2 are used to provide suitable Working level, resistors R3 and R4 provide input impedance matching; the three-stage amplification structure adopts a cascaded full differential amplification structure with low load impedance to amplify the input signal and provide sufficient gain, so that at a given input signal amplitude Within the range, sufficient voltage swing can be obtained on the current switch tube to promote the effective operation of the current switch; the output signal of this embodiment is AC-coupled to the common-cathode VCSEL anode through the capacitor (C1), and the VCSEL anode voltage is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com