Breathable reflective tape and production process thereof

A technology of reflective tape and fabric, which is applied in the field of reflective tape, can solve the problems of poor air permeability, low reflection efficiency of glass beads, and difficult to play an indicating role, and achieve good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

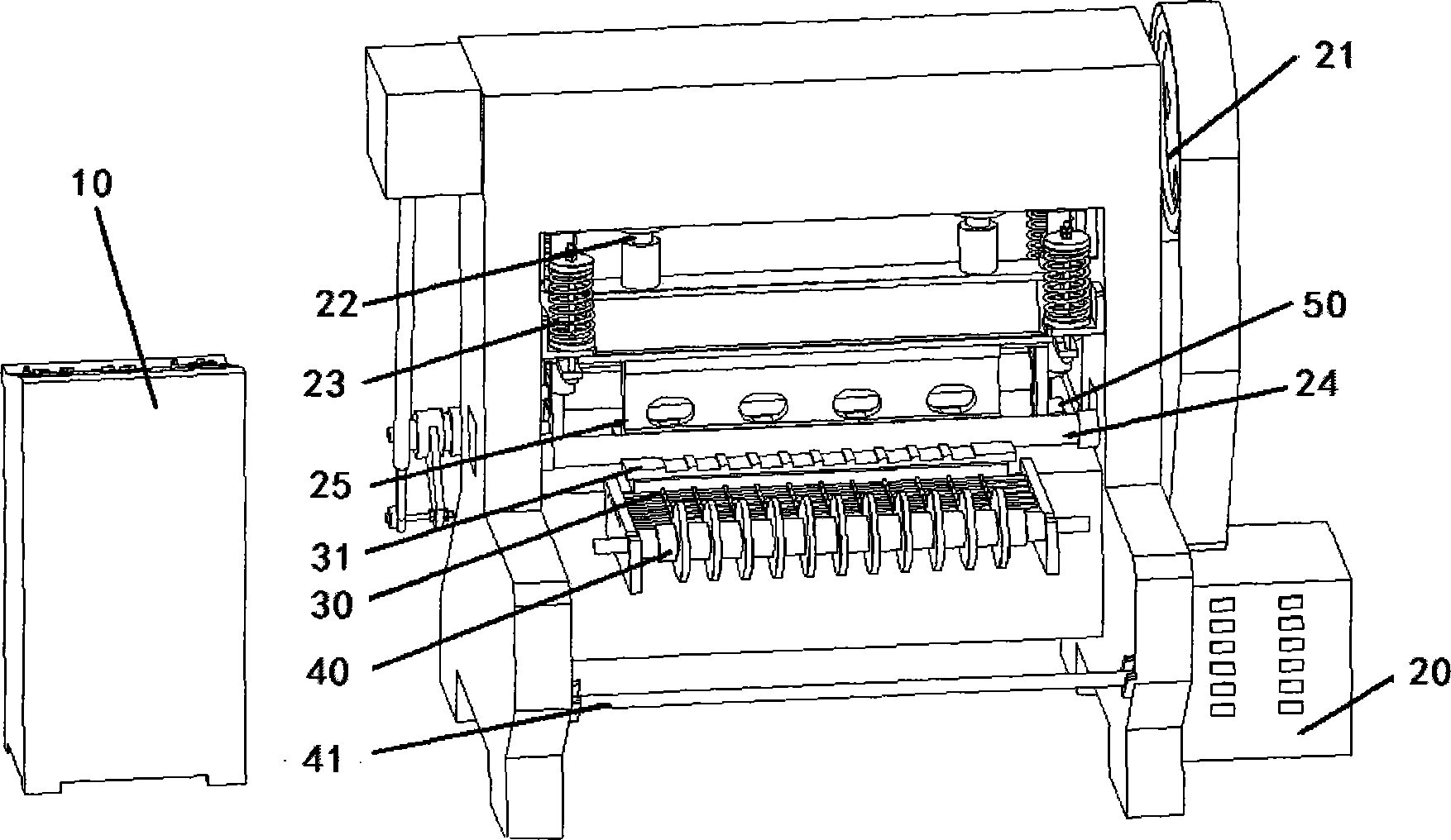

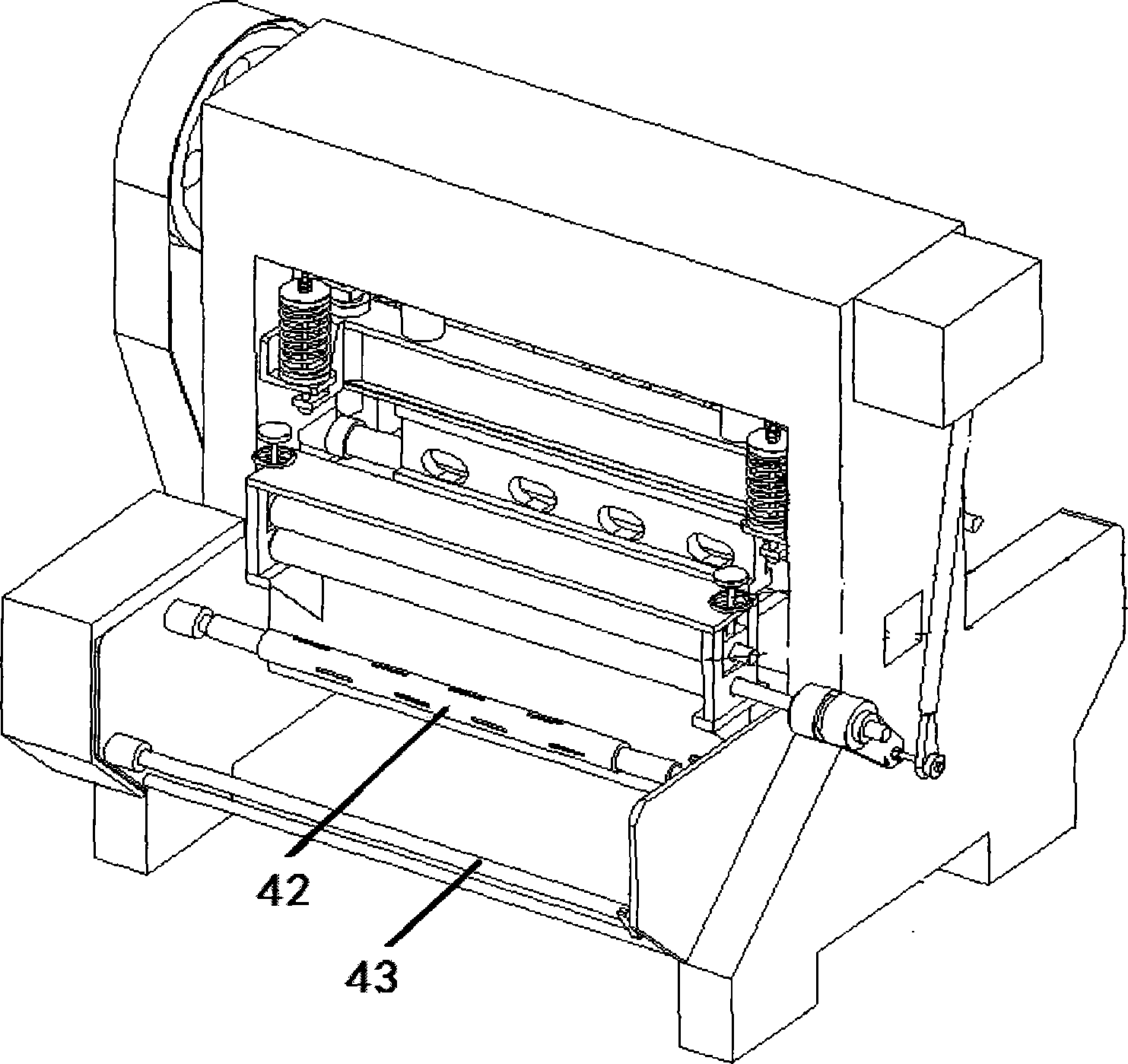

[0022] The air-permeable reflective tape of the present invention, for example, can be attached Figure 1-2 The device is prepared. as attached Figure 1-2 As shown, the described equipment mainly includes electric control mechanism, power and transmission mechanism, feeding mechanism, material distribution mechanism, pressing mechanism, stamping mechanism and receiving mechanism; more specifically, the described equipment includes electronic control mechanism Box 10, driving motor 20, and the transmission belt 21 connected with the driving motor, transmission shaft 22, damping spring 23, punching template 25, pressing roller 24, material distribution plate 31, material distributor 30, feeding device 40 , The upper paper device 41, the finished product roller 42, the delivery roller 43 and the waste discharge device 50. First the bottom layer of the fabric (such as polyester fiber cloth) is placed in the feeding device 40, the bottom layer of the fabric passes through the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com