Integrated grating piezoelectric modulation closed-loop high-precision acceleration micro-sensor

A micro-acceleration, high-precision technology, applied in the direction of speed/acceleration/shock measurement, measurement of acceleration, instruments, etc., can solve the problems of poor accuracy of measurement acceleration, poor interference ability, small measurement range of micro-optical acceleration sensors, etc., to improve Measuring range and effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

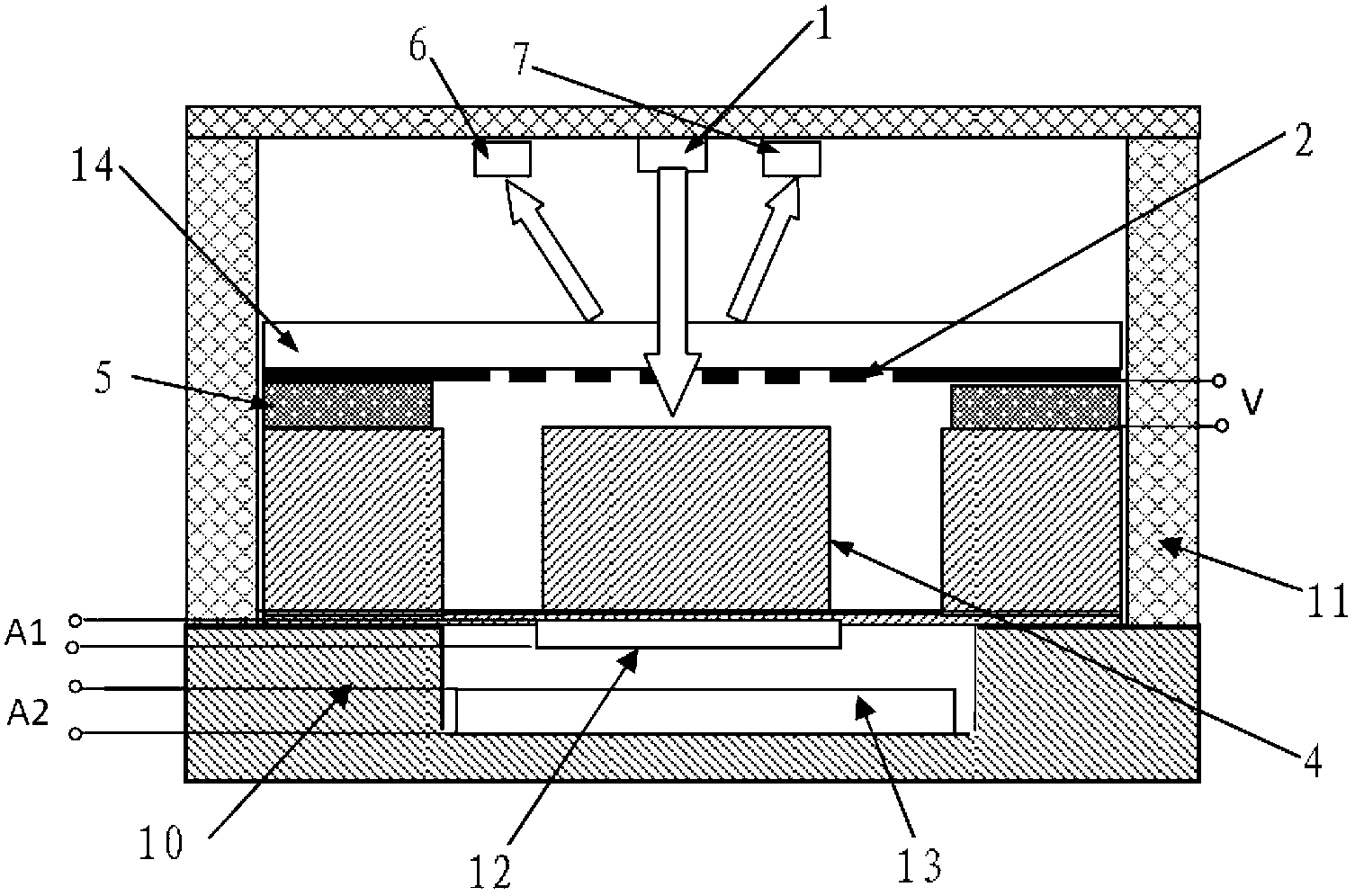

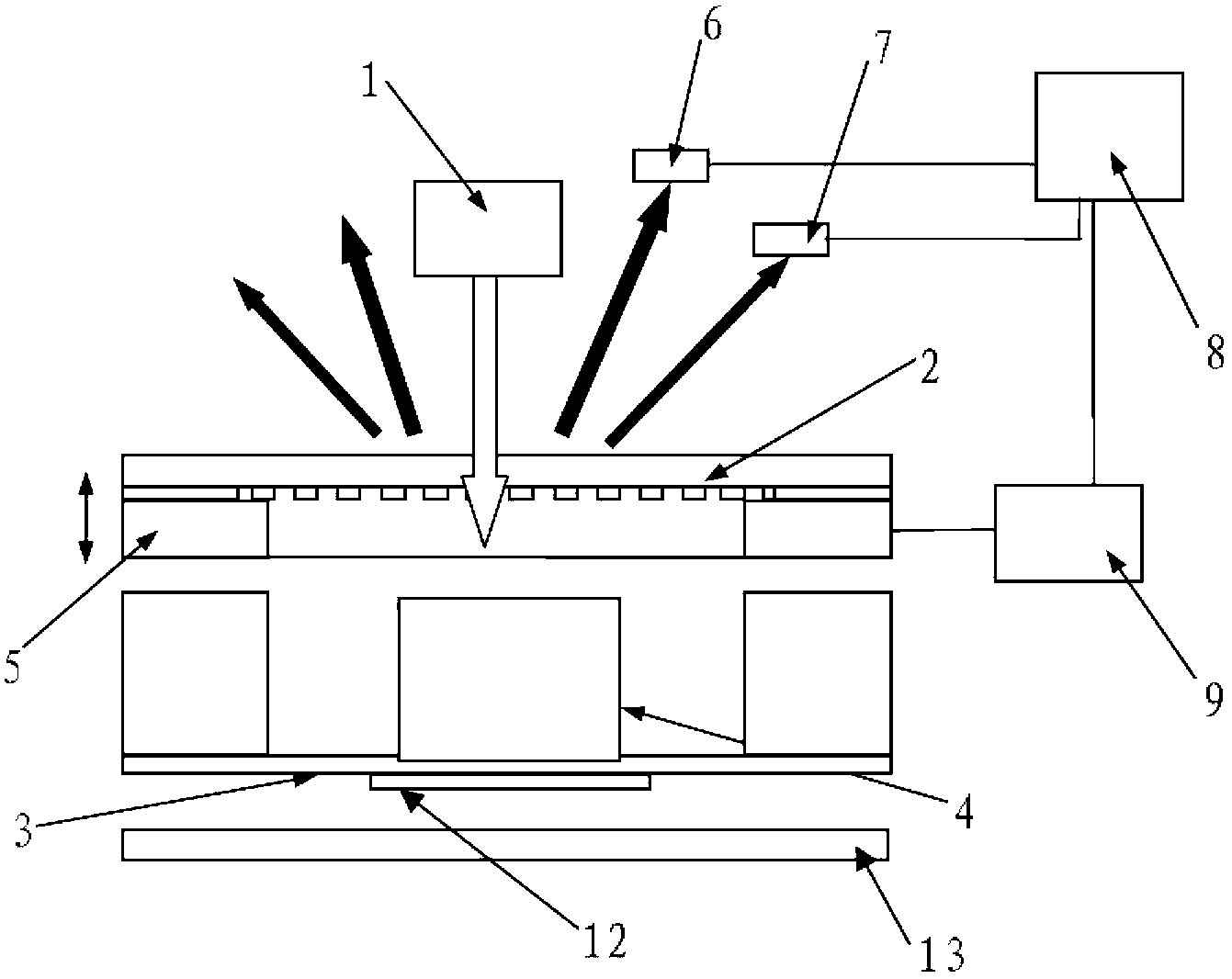

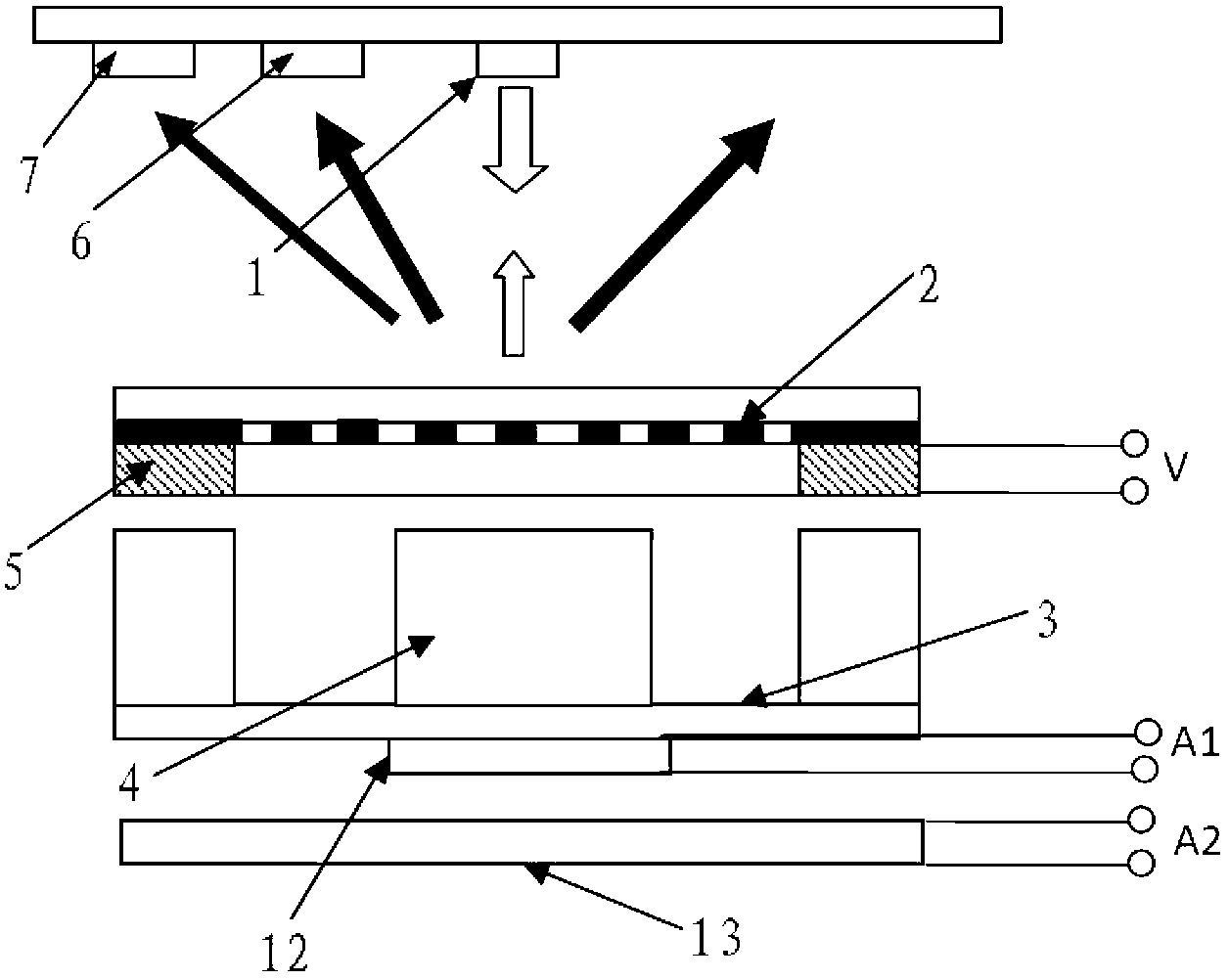

[0029] Such as figure 1 Shown is the micro-optical acceleration sensor of the present invention, comprising a housing 11, a base 10 positioned at the bottom of the housing 11, a MEMS sensing mechanism with a mass 4 and a cantilever beam 3 is arranged above the base 10, and the MEMS sensing mechanism is installed on the housing 11, the base 10 has an accommodation chamber adapted to the mass block 4, which provides space for the displacement of the mass block 4, the bottom of the mass block 4 is fixed with a multi-layer planar spiral coil 12, and the bottom of the accommodation chamber is fixed with Multi-layer planar spiral coil 13.

[0030] A metal grating 2 is arranged above the MEMS sensing mechanism, and an annular piezoelectric ceramic part 5 is arranged between the metal grating 2 and the MEMS sensing mechanism. Can slide vertically. A vertical cavity surface emitting laser 1, a photodiode 6 and a photodiode 7 are arranged above the metal grating 2 and on the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com