Hydrodynamic test measurement bridge with high control precision

A hydrodynamic and high-precision technology, which is used in fluid dynamics tests, measuring devices, testing of machine/structural components, etc. It can reduce the possibility of damage and false triggering, improve safety and reliability, and have a long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

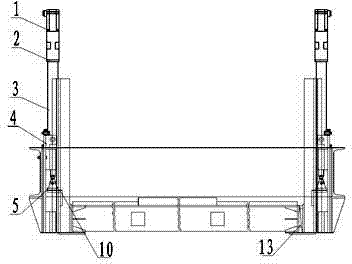

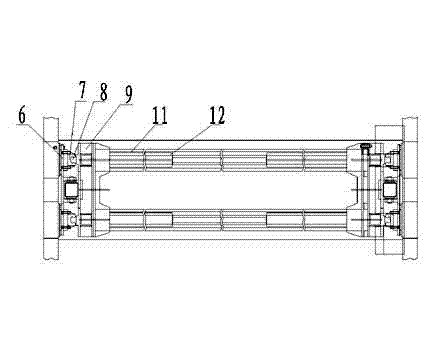

[0026] Such as figure 1 , 2 As shown, the present invention consists of an AC servo motor 1, a planetary reducer 2, a servo electric cylinder 3, an electric cylinder fixing seat 4, a lifting seat 5, a beam connecting plate 6, a linear slider 7, a linear slide rail 8, and a bridge connector 9 , connecting seat 10, central bridge frame 11, instrument fixed track 12 and length compensation inclined block 13. The beam connecting plate 6 is connected with the beam of the test trailer through bolts and nuts to become the fixing part of the whole set of test and measurement bridge frame. AC servo motor 1, The planetary reducer 2 and the servo electric cylinder 3 are fixed on the crossbeam connecting plate 6 through the electric cylinder fixing seat 4, the power output shaft of the AC servo motor 1 is connected with the servo electric cylinder 3 through the planetary reducer 2, and the crossbeam connecting plate 6 The fixed linear slider 7 is slidingly connected to the fixed linear s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com