High-frequency closely-spaced piezoelectric film hydrophone array and production method thereof

A technology of piezoelectric film and hydrophone array, applied in the field of high-frequency hydrophone array and its preparation, to achieve the effects of improving detection resolution, overcoming array element position errors, and enhancing electromagnetic compatibility and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

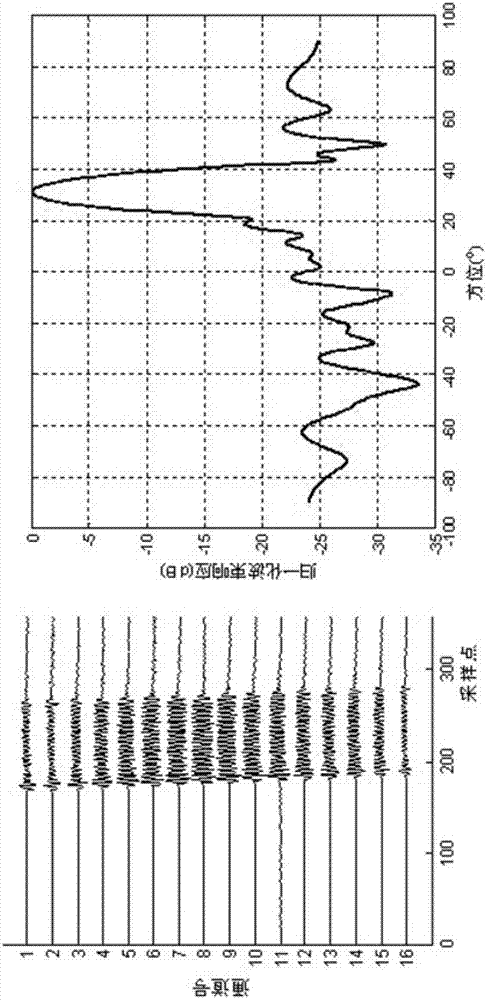

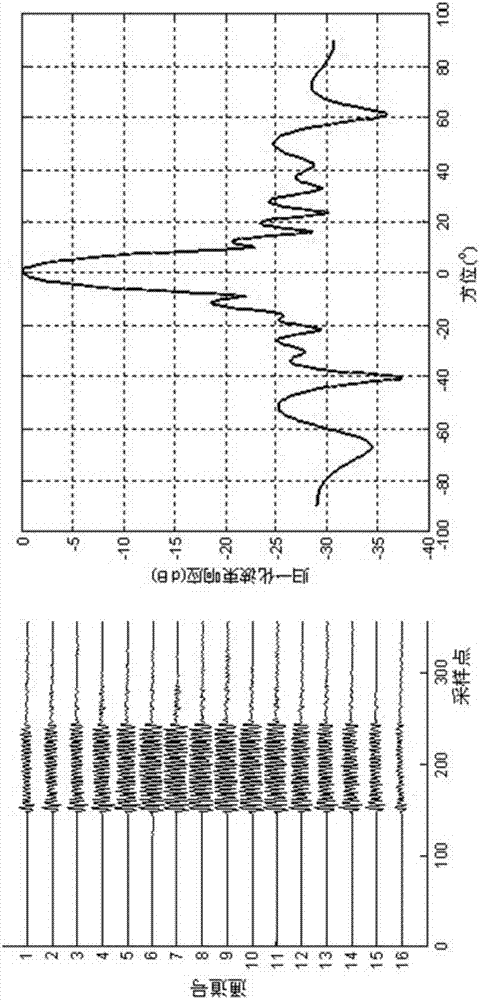

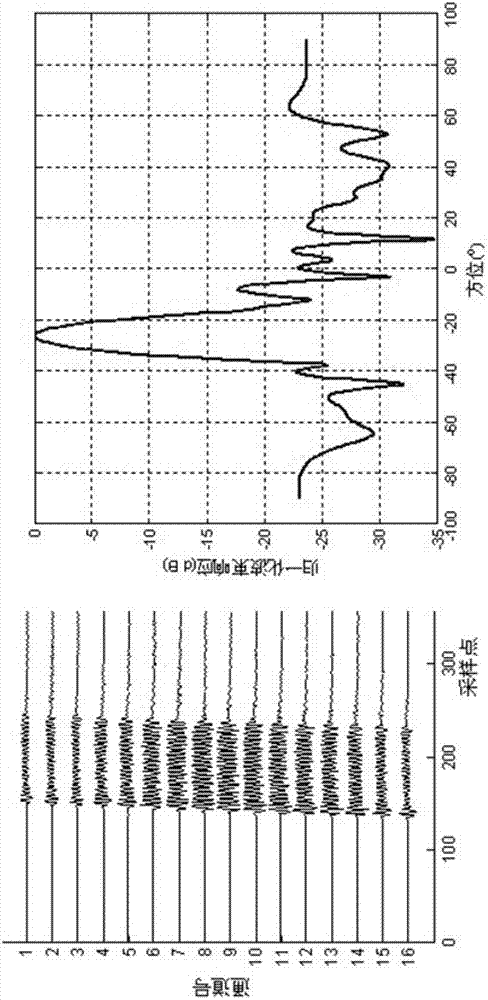

[0041] see Figure 1 ~ Figure 3 , the present embodiment is a high-frequency close-packed piezoelectric film hydrophone base array prepared by the technical solution of the present invention, seawater-resistant polyurethane is used as the sound-transmitting sealing jacket 1, and the entire PVDF piezoelectric film 3 is used as 256 arrays The sensitive material of the hydrophone, the upper surface of the PVDF piezoelectric film 3 is a full-through electrode, the common ground electrode 2 is introduced into the PCB circuit board 7, and the bottom of the piezoelectric film 3 is a brass backing plate 5 to form a 16×16 element hydrophone The sensor array and the array element frame are used as the hydrophone sensitization parts, the cork rubber 4 is used between the backing particles to decouple the array elements, and the multi-layer PCB circuit board 7 u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com