Miniature heat exchanger

A heat exchanger and micro technology, applied in heat exchange equipment, cleaning heat transfer devices, lighting and heating equipment, etc., can solve the problems of insufficient heat exchange and low heat exchange efficiency of the medium, and achieve excellent corrosion resistance, The effect of prolonging the service life and improving the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

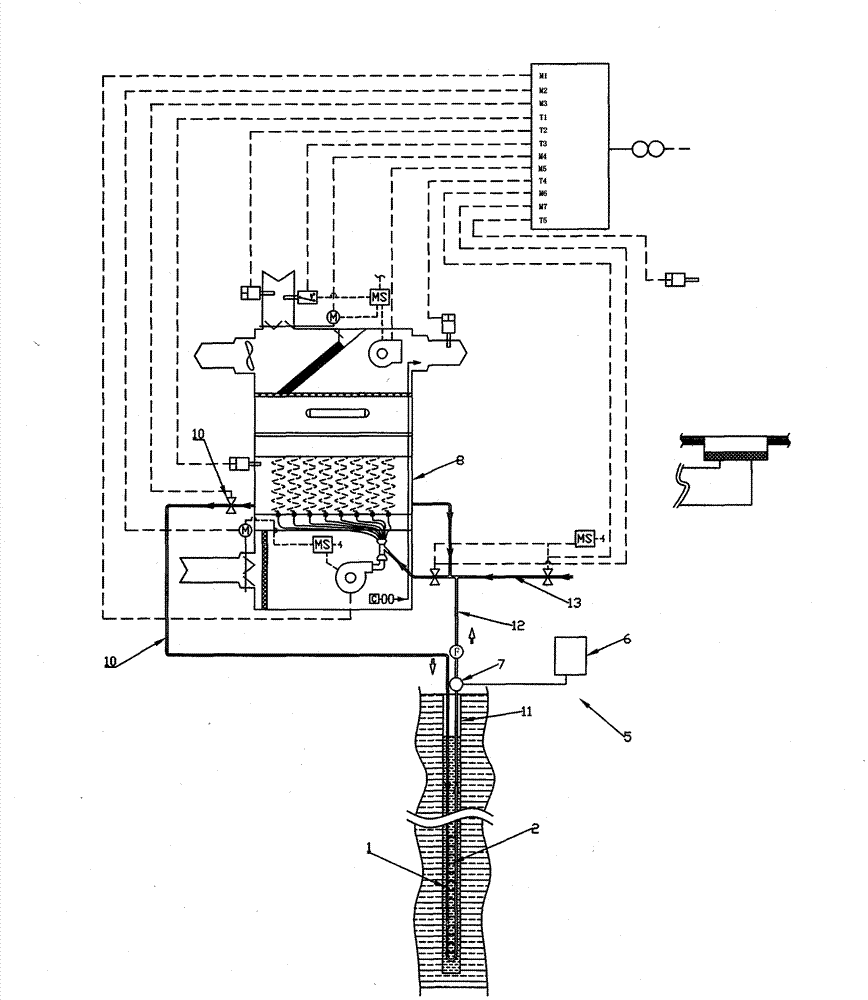

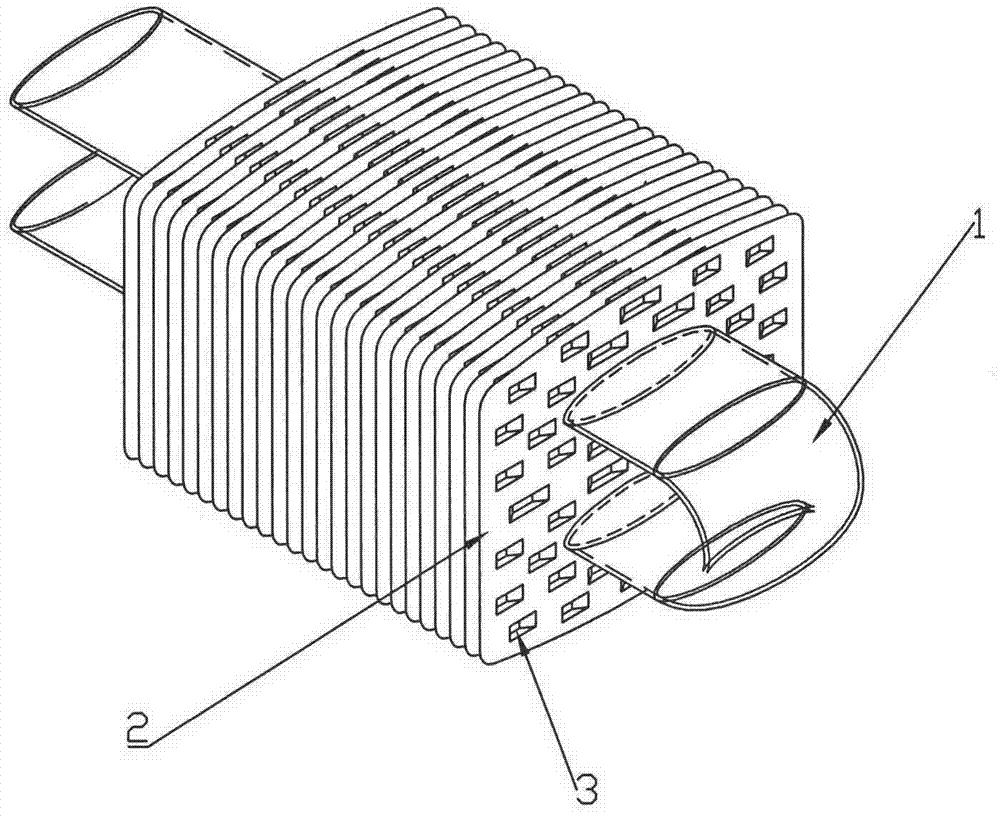

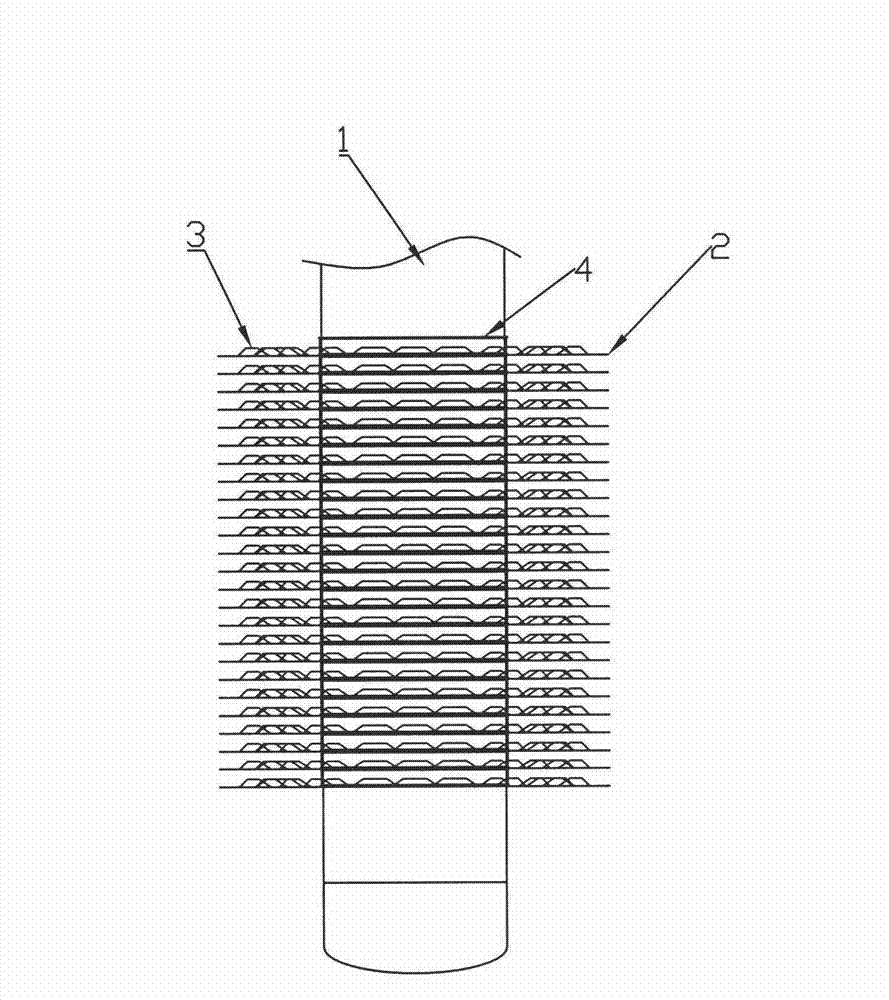

[0019] Such as Figure 1-4 As shown, the miniature heat exchanger includes an elliptical U-shaped tube 1 and a heat exchange fin 2; the heat exchange fin 2 is provided with a heat conduction window 3 and an ellipse sleeve 4, and the heat conduction window 3 has different sizes and Staggered distribution, several heat exchange fins 2 are stacked and the heat conduction windows 3 and elliptical sleeves 4 on each layer of heat exchange fins 2 are aligned respectively; the heat exchange fins 2 are set on the elliptical U On the tube 1, the elliptical casing 4 and the elliptical U-shaped tube 1 are fastened by a high-pressure internal mold expansion tube or a mechanical expansion tube; the heat conduction window 3 protrudes upward from the heat exchange fin 2 in a trapezoidal shape Body structure, the bottom surface, front side, rear side and inside of the trapezoid body are through structures; the heat exchange fins 2 are made of SUS304 or other corrosion-resistant materials with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com