Preparation method of galactose vinyl ester/isopropyl acrylamide copolymer nanofiber membrane

A technology of propylacrylamide copolymer and isopropylacrylamide, which is applied in the direction of textiles, papermaking, non-woven fabrics, etc., to achieve the effects of controllable LCST value, improved biocompatibility, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

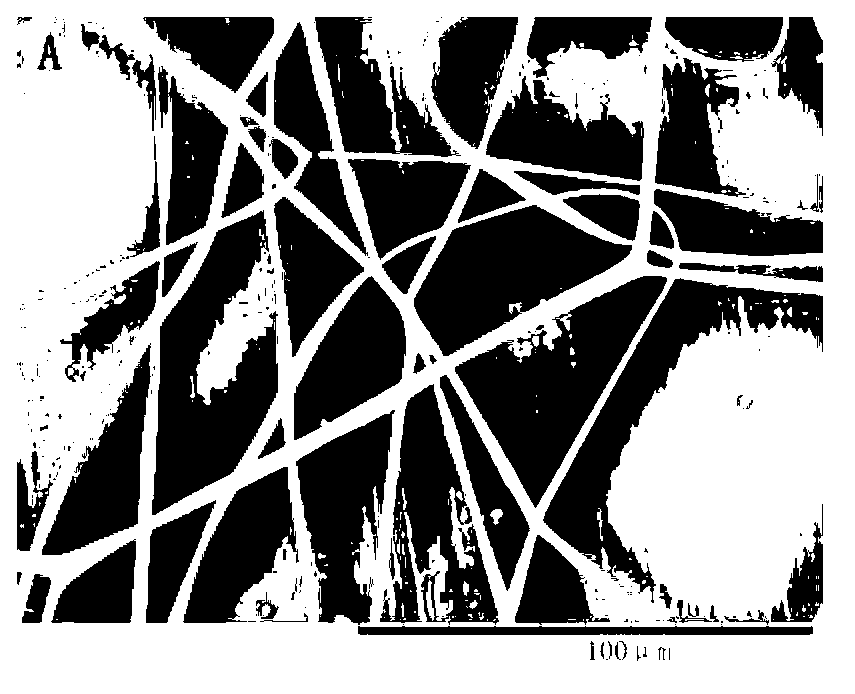

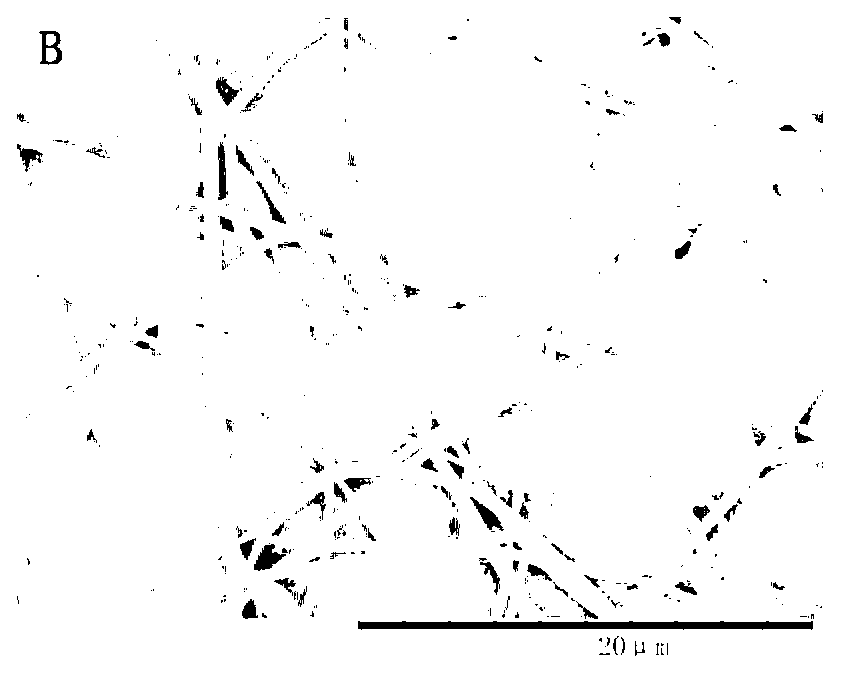

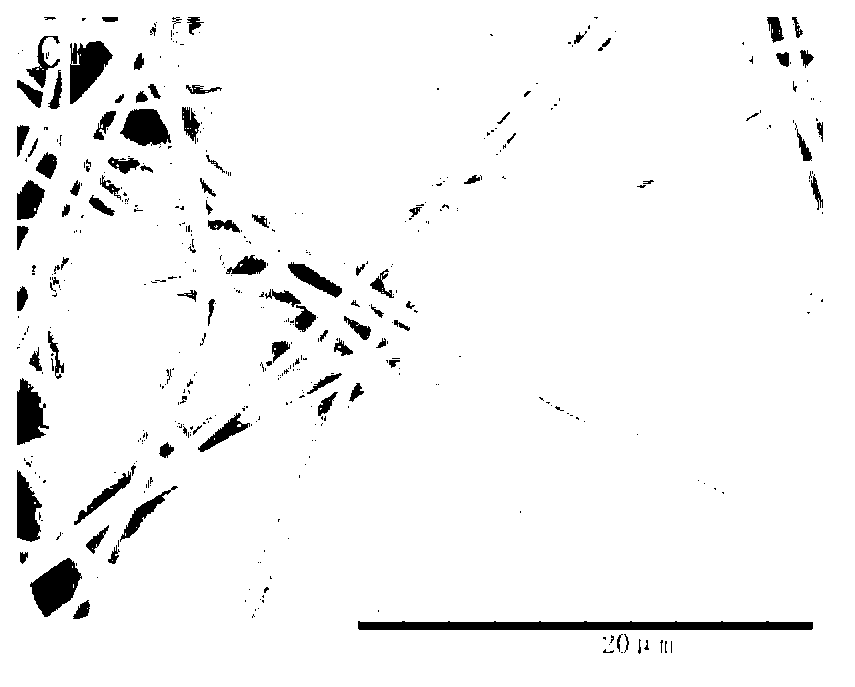

Image

Examples

Embodiment 1

[0039](1) Divinyl azelate and galactose were dissolved in anhydrous pyridine at a certain ratio (4:1, molar ratio), and galactose vinyl ester was synthesized by enzymatic synthesis technology. After the reaction, the crude product was separated and purified by silica gel column chromatography, the eluent was ethyl acetate, and the developing solvent was ethyl acetate, methanol and water (17:3:1, v / v / v). 2 color. Put the above-mentioned glycolipids in a micropolymerization tube, add a certain amount of N-isopropylacrylamide (the molar ratio to glucose ethylene lipid is 7:1), and use azobisisobutyronitrile (AIBN) (accounting for galactose Vinyl ester and N-isopropylacrylamide (the mass fraction of the total mass is 2.0) as the initiator, adding absolute ethanol as the solvent (the monomer concentration is 2.5mol / L absolute ethanol), sealed, and vacuumized by an oil pump Nitrogen, repeated several times. The system was placed at 50-60° C. under the protection of nitrogen and st...

Embodiment 2

[0046] (1) Divinyl azelate and galactose were dissolved in anhydrous pyridine at a certain ratio (4:1, molar ratio), and galactose vinyl ester was synthesized by enzymatic synthesis technology. After the reaction, the crude product was separated and purified by silica gel column chromatography, the eluent was ethyl acetate, and the developing solvent was ethyl acetate, methanol and water (17:3:1, v / v / v). 2 color. Add a certain amount of N-isopropylacrylamide (the molar ratio of galactose vinyl ester is 7:1), and use azobisisobutyronitrile (AIBN) (accounting for galactose vinyl ester and N-isopropylacrylamide The mass fraction of the total mass is 2.0) as an initiator, adding absolute ethanol as a solvent (the monomer concentration is 2.5mol / L absolute ethanol), sealing, vacuuming with an oil pump, and passing nitrogen gas, repeating many times. The system was placed at 55-60° C. under the protection of nitrogen and stirred for 6 h.

[0047] (2) Add a certain mass of temperat...

Embodiment 3

[0053] (1) Divinyl azelate and galactose were dissolved in anhydrous pyridine at a certain ratio (4:1, molar ratio), and galactose vinyl ester was synthesized by enzymatic synthesis technology. After the reaction, the crude product was separated and purified by silica gel column chromatography, the eluent was ethyl acetate, and the developing solvent was ethyl acetate, methanol and water (17:3:1, v / v / v). 2 color. Put the above-mentioned glycolipid in a micropolymerization tube, add a certain amount of N-isopropylacrylamide (the molar ratio of galactose vinyl ester is 7:1), and use azobisisobutyronitrile (AIBN) (accounting for half The total mass fraction of lactose vinyl ester and N-isopropylacrylamide is 2.0) as an initiator, add absolute ethanol as a solvent (monomer concentration is 2.5mol / L absolute alcohol), seal, and vacuumize with an oil pump Nitrogen, repeated several times. The system was placed at 50-60° C. under the protection of nitrogen and stirred for 6 h.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com