Microalgae grease extraction method

A technology of microalgae oil and extraction method, which is applied in the direction of fat oil/fat production and fat production, which can solve the problems of loss of biologically active components, high temperature, and long time, and achieve low cost, low energy consumption, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

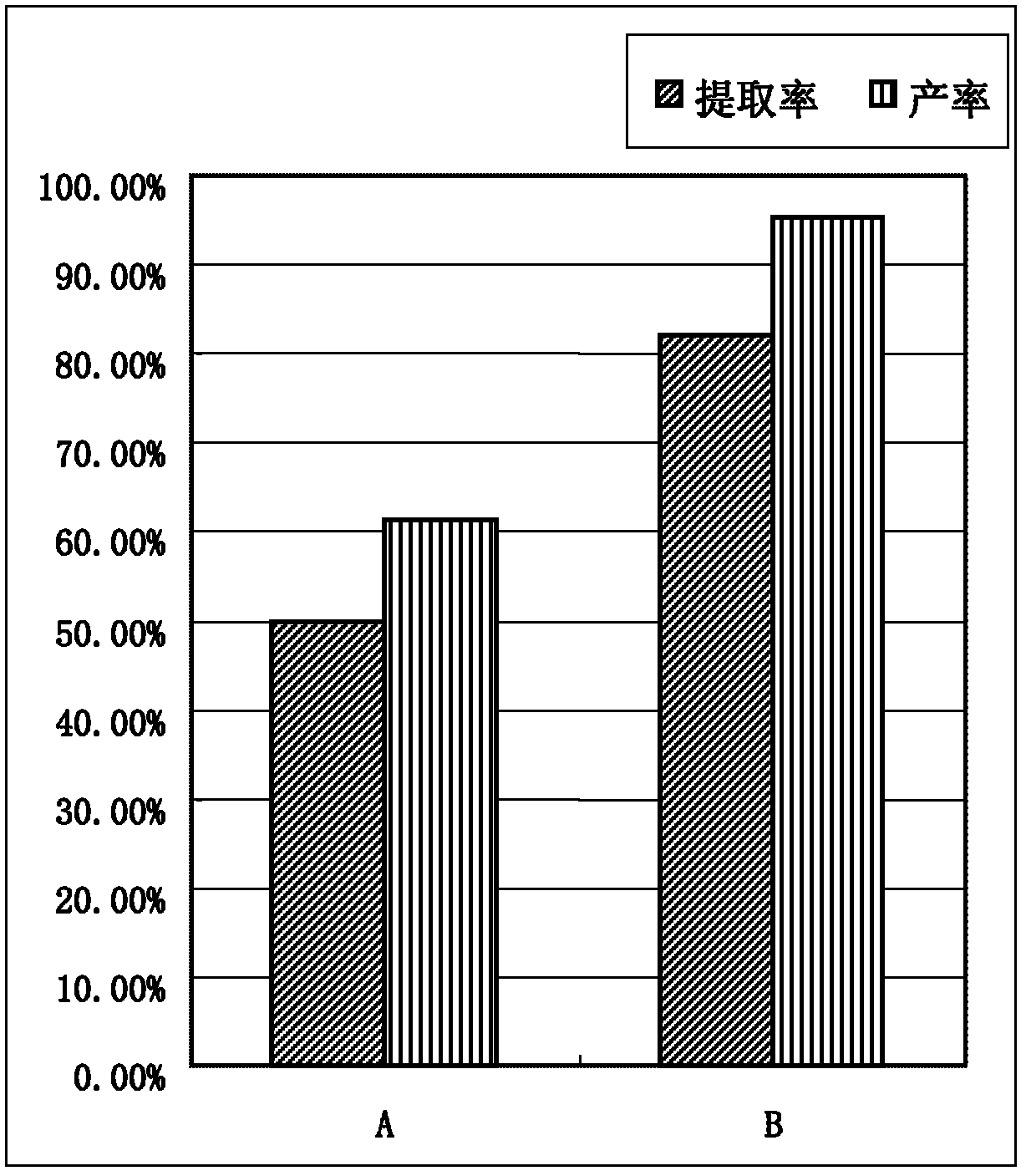

[0036] Oil extraction using wet algae, a species of Chlorococcus. Design two experimental groups A and B, each with 3 parallel samples, take 30g of wet algae from each sample, and adjust the final concentration of wet algae to 100g / L according to the water content. Add dilute sulfuric acid to both groups A and B until the pH value is 2, seal them with sealing film, and treat them at 135°C and 0.2 MPa for 1 min; then add 0.1 g of acid cellulase, 0.02 g of acid pectinase, Acid protease 0.05g, 40°C, 120rpm oscillating for 12h; group B added 0.1g of acid cellulase, acid pectinase 0.02g, 40°C, 120rpm oscillating for 6h, then added acidic protease 0.05g, 40°C, Continue to shake and vortex at 120rpm for 6h.

[0037] Put each algae sample in a 500mL conical flask, add n-hexane at a ratio of 1:10 (algae dry weight / solvent, DWg / mL), fully stir and extract in a water bath at 50°C for 20min, centrifuge at 3000rpm for 3min, and transfer the supernatant ; Repeat this step three times. Th...

Embodiment 2

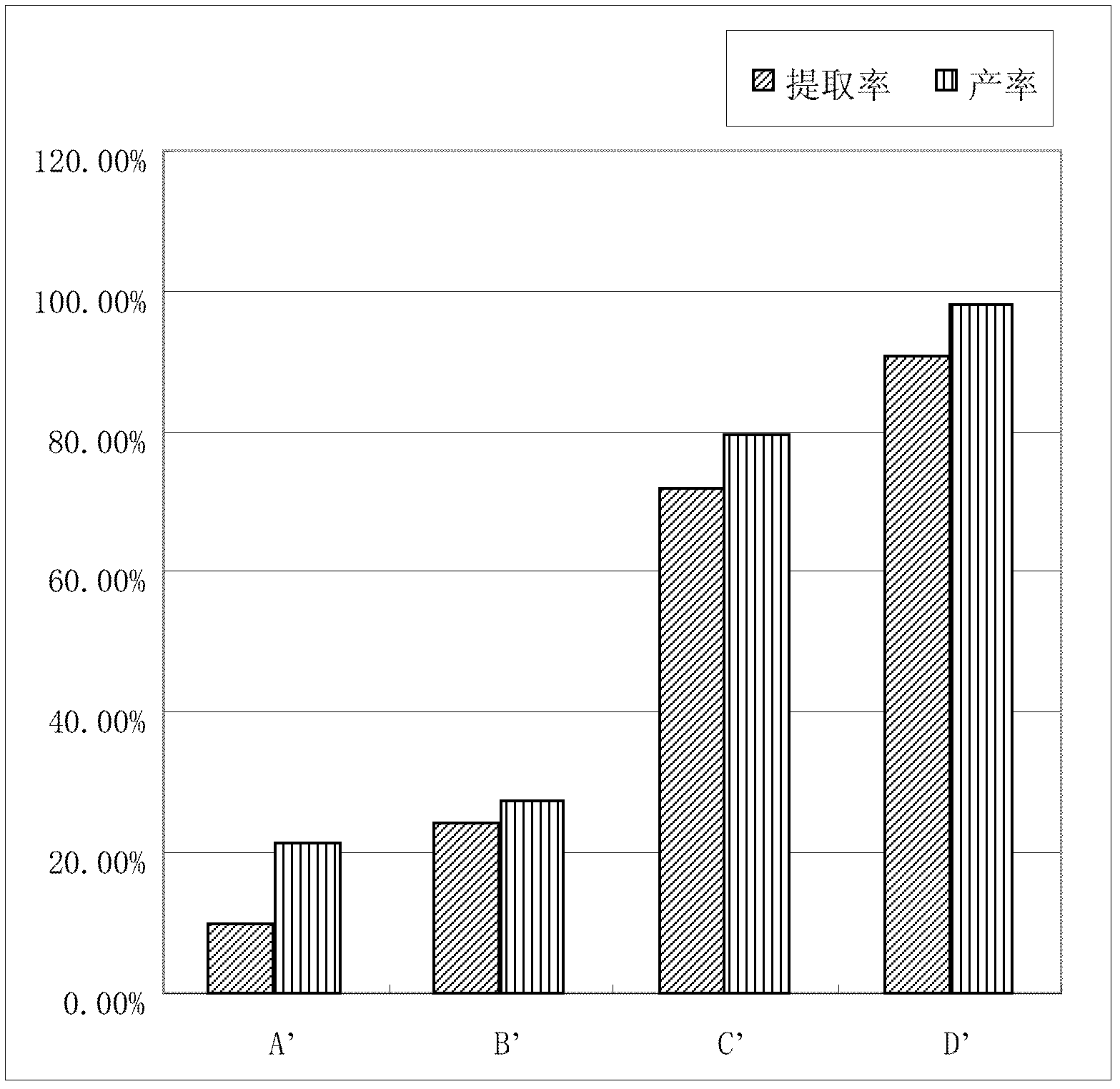

[0042] Oil extraction was carried out with wet algae, a type of Scenedesmus. Design four experimental groups as shown in Table 2, each with 3 parallel samples, take 30 g of wet algae from each sample, and adjust the final concentration of wet algae to 100 g / L according to the water content.

[0043] Table 2

[0044] Experimental group number

Treatment of experimental group

A’

none

B’

pH=2, enzyme treatment

C’

High temperature and high pressure, pH=2

D’

High temperature and high pressure, pH=2; enzyme treatment

[0045] Group A' is the control group without any treatment; groups C' and D' add dilute sulfuric acid until the pH value is 2, seal them with sealing film, and treat them at 135°C and 0.2MPa for 1 min; group B' add dilute sulfuric acid until the pH value is 2. The pH value is 2, add 0.1g of acid cellulase and 0.02g of acid pectinase to the cooled D' group, shake and mix at 40°C and 120rpm for 6h,...

Embodiment 3

[0051] Oil extraction was performed using wet algae, a species of Scenedesmus. Design two experimental groups A and B, each with 3 parallel samples, take 30g of wet algae from each sample, and adjust the final concentration of wet algae to 100g / L according to the water content. Group A is the control group without any treatment; Group B is added with dilute sulfuric acid until the pH value is 1.5, sealed with bottle sealing film, and treated at 150°C and 0.1MPa for 120min; then add 0.1g of acid cellulase and acid pectinase 0.02g, 0.05g acid protease, shake and vortex at 30°C and 30rpm for 48h.

[0052] Put each algae sample in a 500mL conical flask, add n-hexane at a ratio of 1:10 (algae dry weight / solvent, DWg / mL), fully stir and extract in a water bath at 50°C for 20min, centrifuge at 3000rpm for 3min, and transfer the supernatant ; Repeat this step three times. The supernatants were combined, filtered through filter paper, and the solvent was distilled off with a rotary e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com