High-nitrogen fluid compound fertilizer containing multiple protein fluid nutrient elements and preparation method thereof

A compound fertilizer and protein solution technology, applied in fertilization methods, fertilizer mixtures, fertilization devices, etc., can solve the problems of insufficient functional liquid fertilizers in comprehensive utilization of resources, no substantial improvement in fertilizer products, and backward liquid fertilizers, etc., to achieve nutrient distribution The effect of being flexible and changeable, reducing environmental pollution and ecological damage, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

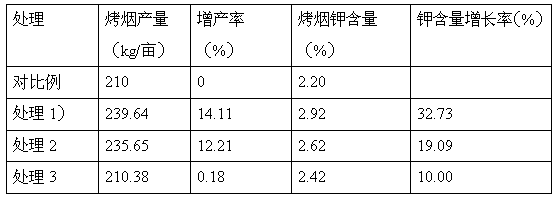

Examples

Embodiment 1

[0043] Prepare raw materials according to the following parts by weight:

[0044] Protein liquid 28 parts by weight;

[0045] 30 parts by weight of urea;

[0046] 13 parts by weight of ammonium dihydrogen phosphate;

[0047] Potassium sulfate 10 parts by weight;

[0048]Potassium chloride 11 parts by weight;

[0049] 5 parts by weight of hydroxyethyl cellulose;

[0050] 3 parts by weight of sodium bentonite.

[0051] All the solid fertilizers mentioned above are made by crushing the raw materials of the fertilizer through the LP series vertical chain crusher, and then passing through a 100-mesh sieve.

[0052] Fertilizer preparation method:

[0053] S1. Take 28 parts by weight of the protein solution and heat it to 70°C, keep the temperature at 70°C, add 5 parts of hydroxyethyl cellulose, stir to dissolve it; then add 3 parts of sodium bentonite, stir while adding, and finish adding the two Stir the ingredients for another 25 minutes to fully mix the two components to m...

Embodiment 2

[0060] Prepare raw materials according to the following parts by weight:

[0061] Protein solution 30 parts by weight;

[0062] 30 parts by weight of urea;

[0063] 10 parts by weight of ammonium dihydrogen phosphate;

[0064] 7 parts by weight of potassium sulfate;

[0065] Potassium chloride 15 parts by weight;

[0066] 5 parts by weight of hydroxyethyl cellulose;

[0067] 3 parts by weight of sodium bentonite.

[0068] Fertilizer preparation method:

[0069] (1) Take 30 parts by weight of the protein solution and heat it to 80°C, keep the temperature at 80°C, add 5 parts of hydroxyethyl cellulose, stir to dissolve it; then add 3 parts of sodium bentonite, stir while adding, and finish adding the two Stir the ingredients for another 15 minutes to fully mix the two components to make a suspension;

[0070] (2) Slowly add 30 parts of urea, 10 parts of ammonium dihydrogen phosphate, 7 parts of potassium sulfate and 15 parts of potassium chloride to the suspension prepare...

Embodiment 3

[0076] Prepare raw materials according to the following parts by weight:

[0077] Protein solution 35 parts by weight;

[0078] 34 parts by weight of urea;

[0079] 8 parts by weight of ammonium dihydrogen phosphate;

[0080] 7 parts by weight of potassium sulfate;

[0081] Potassium chloride 9 parts by weight;

[0082] 4 parts by weight of hydroxyethyl cellulose;

[0083] 3 parts by weight of sodium bentonite.

[0084] The preparation method of fertilizer is the same as embodiment 1 or 2.

[0085] The appearance of the obtained liquid fertilizer is a black liquid with good uniformity and suspending property, the nitrogen content is 241 g / L, and the phosphorus content (P 2 o 5 ) is 57 g / L, potassium content (K 2 O) is 135 g / L, and the fertilizer density is 1.43g / cm 3 , containing 3.62~7.24% protein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com