Method for preparing porous nano magnesium silicon based block body thermoelectric material by hot press method in electric field reaction

A technology of electric field reaction hot pressing and thermoelectric materials, applied in the direction of metal silicide, etc., can solve the problems of reducing the thermoelectric transmission performance of Mg2Si thermoelectric materials, complex preparation process, lowering reaction temperature, etc., to reduce the thermal conductivity of the product and achieve high purity. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

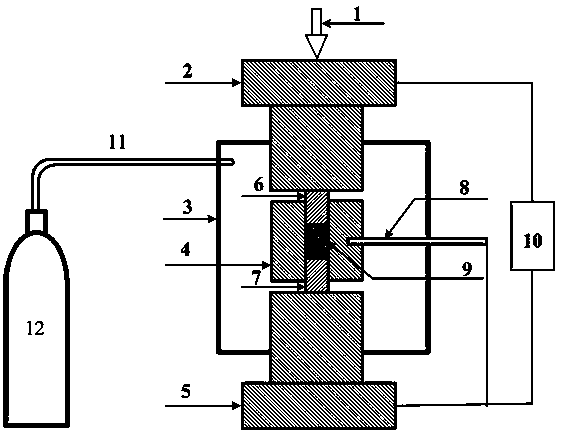

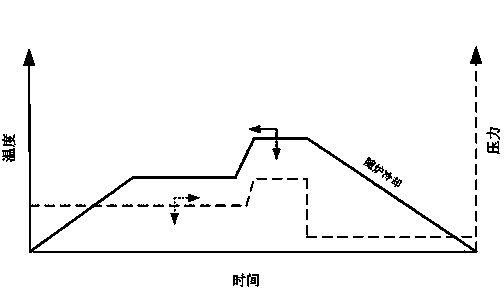

[0014] The reactant MgH 2 Powder (particle size≤45μm, purity≥99.5%), nano Si powder (particle size≤50nm, purity≥99.90%), rare earth metal Y powder (particle size≤45μm, purity≥99.5%) and heavy metal Bi powder (particle size ≤45μm, purity ≥99.5%), the molar mixing ratio is 1.995:0.995:0.005:0.005 (x=0.005, y=0.005), ball milling for 1-3 hours to ensure uniform mixing to form a mixed powder 9, and then the mixed powder 9 Place between the upper indenter 6 and the lower indenter 7 in the graphite mold 4, place the assembled graphite mold in the reaction chamber 3, contact the upper electrode 2 and the lower electrode 5, vacuumize to below 10Pa, and then Pass the Ar protective gas 11 into the cavity from the gas cylinder 12 until the pressure in the cavity reaches 10 5 Pa and keep. Turn on the commercial frequency AC power supply 10 and pressurize 1 in one direction to realize synchronous reaction and sintering densification. Set the heating rate of the powder to 35°C / min. When ...

Embodiment approach 2

[0016] The reactant MgH 2 Powder (particle size≤45μm, purity≥99.5%), nano Si powder (particle size≤50nm, purity≥99.90%), rare earth metal Y powder (particle size≤45μm, purity≥99.5%) and heavy metal Bi powder (particle size ≤45μm, purity ≥99.5%), the molar mixing ratio is 1.995:0.099:0.005:0.01 (x=0.005, y=0.01), ball milling for 1-3 hours to ensure uniform mixing to form a mixed powder 9, and then the mixed powder 9 Place between the upper indenter 6 and the lower indenter 7 in the graphite mold 4, place the assembled graphite mold in the reaction chamber 3, contact the upper electrode 2 and the lower electrode 5, vacuumize to below 10Pa, and then Pass He protective gas 11 into the cavity from the gas cylinder 12 until the pressure in the cavity reaches 10 5 Pa and keep. Turn on the commercial frequency AC power supply 10 and pressurize 1 in one direction to realize synchronous reaction and sintering densification. Set the heating rate of the powder to 40°C / min. When the te...

Embodiment approach 3

[0018] The reactant MgH 2 Powder (particle size≤45μm, purity≥99.5%), nano Si powder (particle size≤50nm, purity≥99.90%), rare earth metal Y powder (particle size≤45μm, purity≥99.5%) and heavy metal Bi powder (particle size ≤45μm, purity ≥99.5%), the molar mixing ratio is 1.99:0.99:0.01:0.01 (x=0.01, y=0.01), ball milling for 1-3 hours to ensure uniform mixing, forming mixed powder 9, and then mixing powder 9 Place between the upper indenter 6 and the lower indenter 7 in the graphite mold 4, place the assembled graphite mold in the reaction chamber 3, contact the upper electrode 2 and the lower electrode 5, vacuumize to below 10Pa, and then Pass the 50%Ar+50%He protective gas 11 into the cavity from the gas cylinder 12 until the pressure in the cavity reaches 10 5Pa and keep. Turn on the commercial frequency AC power supply 10 and pressurize 1 in one direction to realize synchronous reaction and sintering densification. Set the heating rate of the powder to 40°C / min. When th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com