Ferroalloy casting modeling device and ferroalloy casting modeling process in front of furnace

A casting molding, ferroalloy technology, which is applied in the equipment, metal processing equipment, casting equipment, etc. that feed molten metal into the mold, can solve the problems affecting product quality, different shapes and sizes, and high labor intensity, and achieve slag production. Improved iron separation effect, consistent shape and size, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

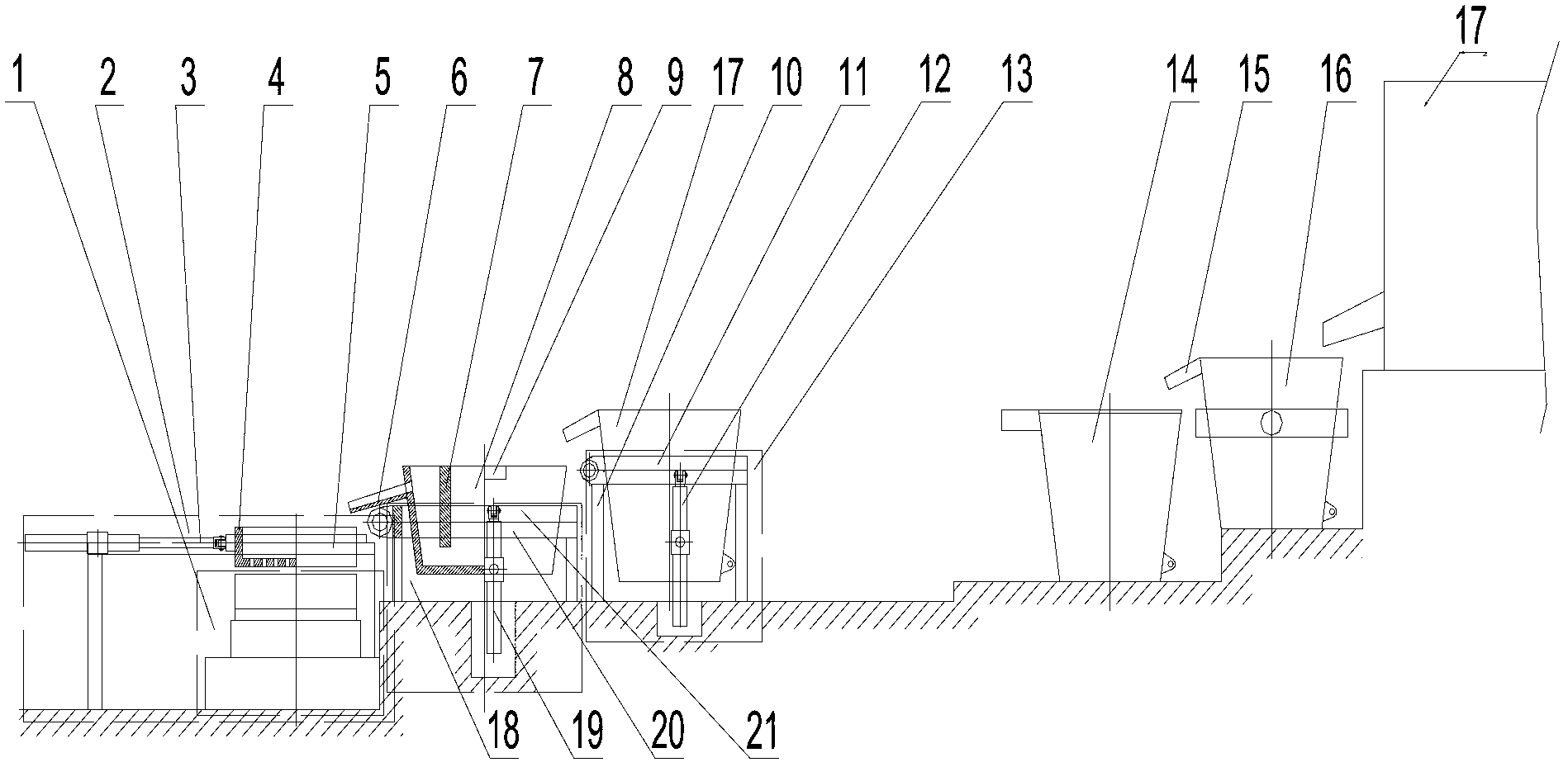

[0032] like figure 1As shown, the pouring molding equipment in front of the ferroalloy furnace of the present invention consists of a ladle 16, a slag ladle 14, a ladle tipping device 13, a slag-iron separation device 18, a pouring tundish device 2 and a cast iron machine 1. Wherein the structure of ladle, slag ladle, ladle tilting device (consisting of fixed frame A10, overturn frame body A11 and hydraulic cylinder A12) and cast iron machine is the same as the prior art, and the volume of ladle 16 is according to different types and different capacities Design of ferroalloy electric furnace and tapping amount of each furnace. Casting machine 1 is composed of sprockets, chains, cast iron molds, etc. The cast iron molds are provided with pits of the same fixed shape according to the requirements of alloy products. Each pit is composed of multiple arc surfaces, and each pit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com