Parallel connection double-junction solar cell

A technology of solar cells and parallel connection, which is applied in the field of solar cells, can solve problems such as complex preparation processes, and achieve the effect of ensuring heavy doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

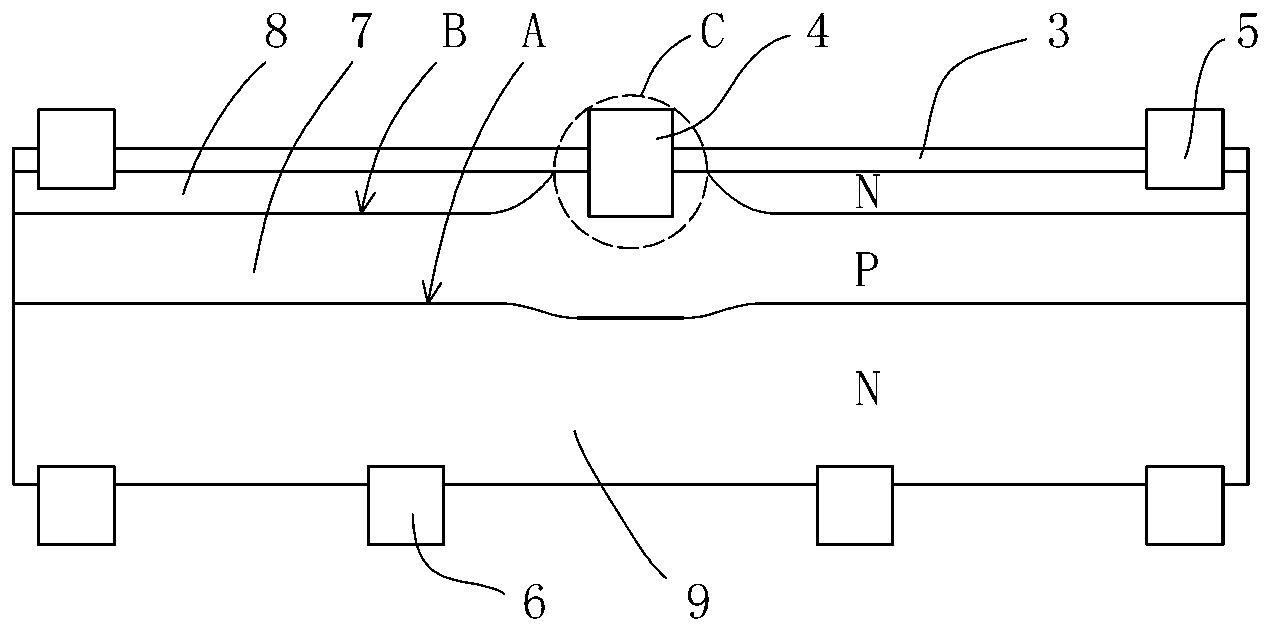

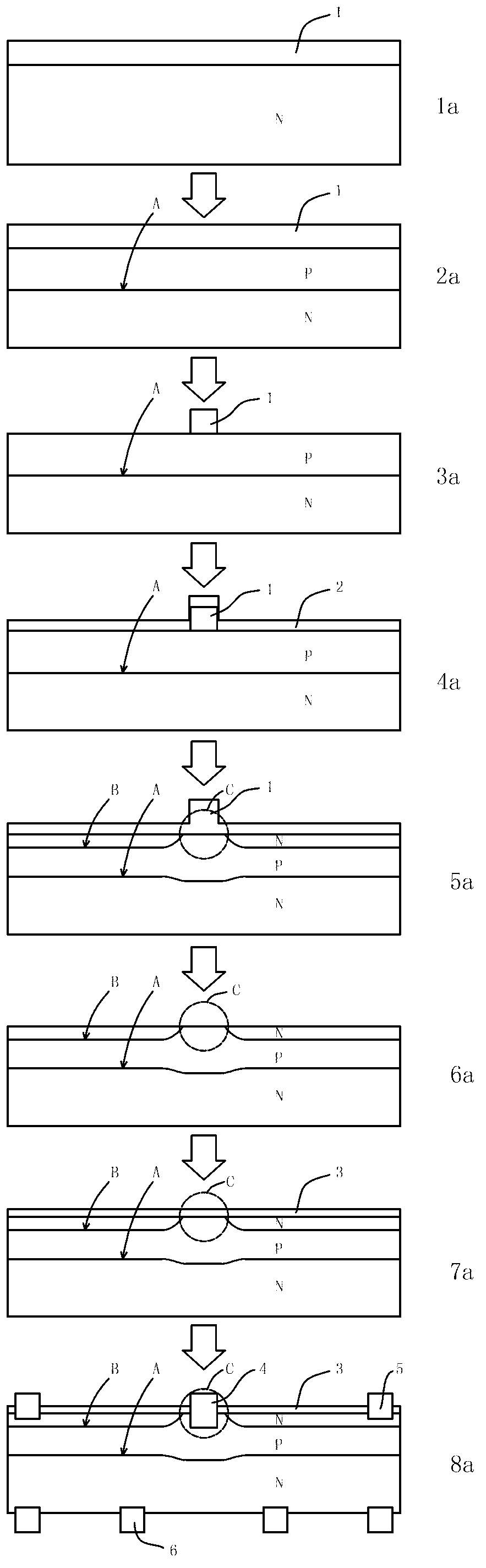

[0040] Such as image 3 As shown, it is a schematic diagram of the manufacturing process flow of the parallel double-junction solar cell of the present invention, and the specific steps of the process are as follows:

[0041] 1a, use magnetron sputtering to deposit a silicon dioxide film 1 with a thickness of about 0.05 microns on the upper surface of the silicon wafer 9 after texturing, and the concentration of boron in the silicon dioxide film 1e19 / cm3 ;

[0042] 2a. Diffusion the deposited silicon wafer at high temperature, so that the doping element (boron) in the silicon dioxide film 1 diffuses into the silicon wafer to form a PN deep junction A;

[0043] 3a. Removing the oxide layer (silicon dioxide film 1) other than the top electrode area on the upper surface of the silicon wafer 9;

[0044] 4a. Depositing an intrinsic amorphous silicon layer 2 on the upper surface of the silicon wafer, the thickness of the deposited intrinsic amorphous silicon layer is about 40nm; ...

Embodiment 2

[0050] The steps of this embodiment are the same as those of Process Example 1, the difference lies in the process parameters of high-temperature diffusion in dry oxygen environment in step 5a (the fifth step). In this embodiment, the process temperature of high-temperature diffusion is 1000°C, and the duration is 5 minute.

Embodiment 3

[0052] The steps of this embodiment are the same as those of Process Example 1, the difference lies in the process parameters of high-temperature diffusion in dry oxygen environment in step 5a (step 5). In this embodiment, the process temperature of high-temperature diffusion is 1100°C, and the duration is 2 minute.

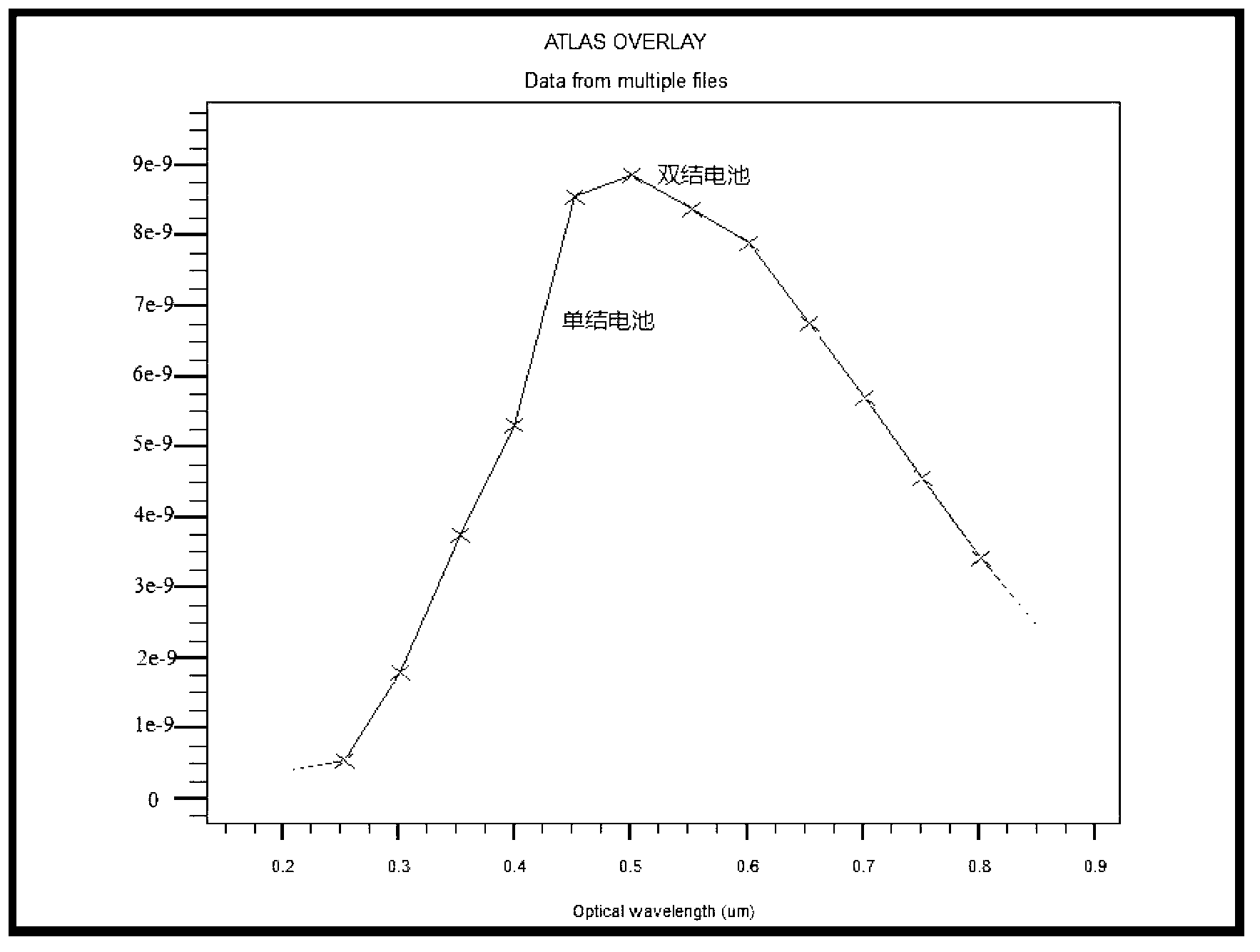

[0053] After simulating the above three process embodiments, it is found through comparison that the PN junction of the battery is continuously deepened with the increase of the high temperature diffusion temperature of the reverse diffusion process. The impurity concentration on the surface of the battery first increases and then decreases, but the impurity concentration in the top electrode region gradually increases with the increase of temperature. The heavily doped impurities in the top electrode region mainly diffuse into the battery body, and the lateral diffusion is small. This is related to the deposition of the intrinsic amorphous silicon layer on the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com